Industry Panel: Exploring Digital Transformation

64 min video / 57 minute readSpeakers

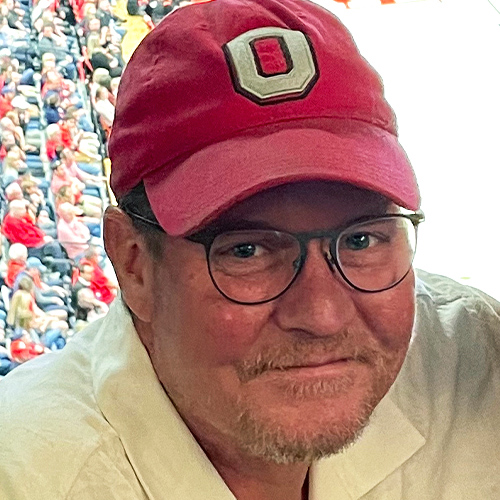

Don Pearson

Chief Strategy Officer

Inductive Automation

Craig Resnick

Vice President

ARC Advisory Group

Jean-Paul Moniz

Technical Services Coordinator

Cameco Fuel Manufacturing

Dan Stauft

Director of Operational Technology

SugarCreek

Keith Weerts

Chief Technical Officer

Blentech Corporation

Ravi Subramanyan

Director of Industry Solutions Manufacturing

HiveMQ

Remus Pop

Sr. Partner Solution Architect

Amazon Web Services (AWS)

It takes coordination to revamp processes or upgrade machinery, but it’s a far more complicated task to establish change all the way from the plant floor to the C-suite. While the necessary Digital Transformation of manual operations may look different across a variety of industries, the critical benefits of increased stability, flexibility, and security remain consistent. Hear from a panel of industry thought leaders and experts as they explore how enterprise-wide solutions have led their companies to a new level of growth and answer your questions about large-scale Digital Transformation.

Transcript:

00:00

Announcer: Welcome to the Industry Panel. Please give a round of applause to Inductive Automation's Chief Strategy Officer, Don Pearson.

00:23

Don Pearson: Well, welcome everyone to the Industry Panel. The theme of the panel this year is “Exploring Digital Transformation,” which happens to be, I think, a very relevant topic. We have some wonderful guests, panelists today to discuss that. They'll be answering your questions. I have a bunch of questions of my own, but if we don't get to my questions 'cause you guys have them ahead of time, we'll just take your questions higher priority. I've already been introduced, so I'm not gonna introduce myself again, but I will be the moderator for this panel, so I think what I would like to do now is since we don't have any panelists yet, let's ask them to come up and join us here.

01:26

Don Pearson: I think what I'm gonna do is read through the bios first, and then I'm gonna come back around, and I will give each of you an opportunity to say a couple of words, a couple of minutes, or something about yourself in relation to the topic, to the company you work for, to the things you work on, things like that. That sound okay to everyone?

01:47

Dan Stauft: Yes.

01:48

Don Pearson: Okay, and then I'm gonna make a noble effort to try and get to as many questions and spread it around to... I won't expect everyone to answer every question, but if I ask you a question and you wanna add something to it, just jump in and add it and we'll just kinda take it from there. There are also people with mics around somewhere, right? Upstairs, downstairs, so yes, thank you. So I definitely wanna have you have the mics available since we are gonna... We do this panel virtually. We wanna make sure we get the questions on the recording also. Alright, first, starting at the far end first with Dan Stauft. He's Director of Operational Technology at SugarCreek. Dan spent 21 years in advanced automotive manufacturing engineering and management with GM, and Toyota, and Nissan. Then about 10 years ago, he joined SugarCreek. It's a private label manufacturer, and he joined them to help spearhead their Digital Transformation. Over the last decade, SugarCreek has grown from Excel and paper-based reporting to implementing a world-class Ignition-based SCADA and MES solution. In fact, in 2017, SugarCreek was awarded the Firebrand Award. I think if it's okay with you folks, I might shorten some of these wonderful bios that you all put together for me, okay? Just gonna kind of do it on the fly here. But there's a whole lot more about Dan. He's an amazing person, okay.

03:21

Don Pearson: Keith Weerts, Chief Technical Officer, Blentech Corporation. Keith Weerts started as a process engineer and a manager working for multinational chemical companies, regularly interacting with the research staff to design processes, products, and applications for sale to food, pharmaceutical, and personal care industries. Later as the Business Development Manager for… Keith worked with Ph.D. researchers to turn their ideas into business opportunities. Major accomplishments include systems for remediating mines and recovery of copper from printed circuit board manufacturers. He's been focused on automation for 25 years, and I think I'll stop there. And let's welcome Keith.

04:16

Don Pearson: Ravi, you are gonna have to really forgive me for not pronouncing your last name. I'll give it a shot, Ravi Subramanyan.

04:23

Ravi Subramanyan: You got it.

04:23

Don Pearson: Okay. Director of Industry Solutions for Manufacturing at HiveMQ. Ravi is a Director of Industry Solutions for Manufacturing at HiveMQ. His expertise covers smart manufacturing, Industry 4.0, and IoT in industries such as mining, O&G, industrial automation, automotive, and fleet management. As a products management leader, he has extensive experience delivering high-quality products and services that have generated revenues and cost savings of over 10 billion for companies such as HiveMQ, Parker Hamlin, GE Digital, Motorola, and others. So please welcome Ravi.

05:05

Don Pearson: And Remus Pop is the Senior Partner Solution Architect with Amazon Web Services. Remus is a recognized industry expert in Industry 4.0 and Digital Transformation, with a long background in manufacturing that spans automotive, aviation, and battery. Remus has helped companies design strategies, deploy and scale smart factory projects across the globe. In his current role as Senior Partner Solution Architect at Amazon Web Services, he continues to help companies understand the value of technology and how to take advantage of cloud services to make that value a reality. Please welcome Remus.

05:47

Don Pearson: Next is Craig Resnick, he's Vice President, Consulting, ARC Advisory Group. I actually asked Craig to sit in sort of late in the game because he did double duty, he just finished a panel next door, but I said you can probably add something to this one, so I appreciate him joining us. He has 35 years experience in sales, marketing, product development, and project management in the industrial market, and gained that experience with major suppliers of PLCs, process control systems, power transmission equipment, and field devices. Craig has been with ARC since 1999. Please welcome Craig Resnick.

06:24

Don Pearson: Jean-Paul Moniz, Technical Services Coordinator, Cameco Fuel Engineering. Jean-Paul Moniz is a 20-plus-year veteran of the factory automation industry. He currently holds the position of Technical Services Coordinator for Cameco's Cobourg facility. He's been leading and implementing factory automation projects his entire career, with experience in aerospace, automotive, and nuclear. Jean-Paul's relentless drive for process efficiency and technology application to solve end-users’ problems makes him wake up in the morning. Hey, I like that, Jean-Paul Moniz. And stay awake in the afternoon, I hope too. Anyway, welcome, Jean-Paul Moniz.

07:13

Don Pearson: Nathan Elmore is a Senior Manager, Warehouse Controls, Walmart Inc. Nathan works for Walmart as the Senior Manager for warehouse controls that primarily focus on Ignition. Nathan oversees integrating Ignition across Walmart’s supply chain. Prior to Walmart, he previously worked in supply chain, automotive, and food industries as a controls engineer. So please welcome Nathan Elmore.

07:43

Don Pearson: So I think what I'd like to do, we'll leave this light up for a while here, so you can sort of see the people here also in the back 'cause we can remember their names then, but Dan, I said I was gonna come back to you and give you an opportunity to share a little bit about maybe the transformation at SugarCreek, maybe your overall background as it relates to today's topic, and maybe I'll ask everybody, since we have a large panel here and I wanna get to questions, just take a couple, three minutes to give us that kind of introduction, and then we're just gonna come down the line, they'll going to you next. Okay?

08:17

Dan Stauft: Perfect.

08:18

Don Pearson: Dan.

08:18

Dan Stauft: Hi. Happy to be here. I spent my first 21 years of my career in automotive for GM, Toyota, and Nissan, and the automotive industry is very data-intensive, and they are lightyears ahead of most manufacturing. Especially in food and bev when it comes to Digital Transformations per se. When I joined SugarCreek in 2013, I was tasked with coming up with, at the time, what was going to be a “machine data collection system.” And we stumbled across Inductive Automation, actually from the recommendation of a Wonderware salesman because we didn't wanna pay Wonderware as much, they said that maybe we could try Inductive Automation 'cause it was this “cheap little start-up” in California. So eight years ago, we got our first gateway. We are 100% internal integrators. We do not use external controls engineers. We don't use anybody external. We built the whole thing in-house. I've got a team of four people that do all the Ignition development for our company that this year is on track to do 1.2 billion in sales from five manufacturing facilities. Don's been through one of our plants, and I think he'll attest. We do everything with Ignition.

09:39

Don Pearson: Thanks Dan. Go.

09:43

Keith Weerts: So I've been in automation for about 25 years now, and one of the things that I think almost anybody who's been an integrator understands is that you can tell your customers, "I've got all this data I can collect for you. All you have to do is use it." And then they get this blank look on their face, and they say, "Yeah, go ahead and collect it." And after you collect a gigabit, two gigabits every year, and for 20 years, they never look at the data. So I finally got fed up with it, and I said, "Well, we need a way to help them see the data. When they see the data, they'll appreciate the data." And that's where I got involved with Ignition because it was the best platform for helping them see it. Fast forward to now, the company I work with is called Blentech, we make food manufacturing equipment, and we supply the automation system for our equipment, and we also supply is a visualization system that is basically a hybrid environment where we transfer the data up into the cloud and then we give them cloud access to their data, so they can see their data, but we put a lot of work into it.

10:46

Keith Weerts: We build platforms that allow them to see their data in a much more meaningful way. It's not always easily accepted. That's probably some of the things we'll talk about today, is people are very resistant to you looking at their data, but we don't share it, we're very careful about how we handle our customer's data, but still, it's not an easy thing to do. Thanks.

11:07

Don Pearson: Thanks Keith. Ravi.

11:11

Ravi Subramanyan: Yeah, thank you for the opportunity, Ravi Subramanyan. I've been in the industry for about 22 years or so, over the past eight years or so, I've been with industrial automation. I worked at GE Digital, and GE started this, coined the term “industrial IoT” and started a Predix platform through which they wanted to move assets to the cloud. That's where I got my initiation into Inductive and Ignition because GE had a HMI/SCADA product and there's a new kid on the block called Inductive and Ignition. They have like this cool solution. So I started looking at it, and over the years, I've spent time with a mining OEM, for example. Trying to create a predictive modeling for their remote operations so they know exactly when to replace them. I know you spent some time in mining, so I would love to get your opinion on that. Like supply-chain optimization. That's typically like a very common use case for data because you have different ERP systems coming together, and over time, they speak different languages.

12:19

Ravi Subramanyan: It's important to bring it all together so people get a single pane of glass when it comes to looking at supply chain and how is it, how to ensure that you know where your parts are, and how you can fulfill the orders. In today's day and age, after COVID, it's become more and more important because there's a lot of strain on supply chain, so I go back to the days that I start doing that. And smart operations and smart manufacturing. That's another area I spent time in. More recently, in the last six months, I joined HiveMQ. HiveMQ offers an enterprise MQTT broker, and we've started having some conversations with Inductive. Looking forward to working with them. So basically, connecting OT assets to IT assets either on the enterprise or the cloud, to be able to do remote monitoring, for example, or to be able to prepare the data for your advanced use cases like AI, ML, and so on and so forth. So I'm looking forward to participating in this panel. Don, Thank you.

13:24

Don Pearson: Thanks, Ravi. Remus.

13:24

Remus Pop: So like Dan, I spent a large majority of my career in an automotive plant or another. I think I've also been on this stage in a lot of different roles throughout the year, so it's pretty interesting to be on this stage in one month and do a new gig I have now with AWS. So it's a pretty exciting time, and I think, obviously, with what Travis and Kevin just showed, that it shows that there's a lot of interest from the cloud providers, specifically AWS, and what's happening in this space. Throughout my career, I've held a couple of different roles, both as an integrator, an end user, and now, kinda a little bit of both. So I'm excited to share some of that knowledge and some of the experiences that we've gone through, but yeah. My background, pretty heavy in controls automation like most people here. That's where I started my career and just migrated through the multiple different steps of where that career path can take you.

14:15

Don Pearson: Thanks, Remus. Craig.

14:17

Craig Resnick: Hello there. I started out, started in the DCS industry, then went to the PLC, pack industry, went into motion control, went into sensors, and then after about 20 years of doing that, I decided, "Why don't I try this thing called being an industry analyst?" So I figured I'd try it for a few months, and then 20 years later, it's still going on. Well, what we do is we work with really three kinds of clients at ARC Advisory Group. One is the people that certainly do the manufacturing and that ranges from clients in aerospace and automotive, so heavy discrete all the way through the Aramcos, and Shells, and Chevrons in heavy process. So we're working with them and trying to help them along with their Digital Transformation strategy. At the same time, we work with all the vendors, and I'd say probably... We can't say we work with every person in the planet that manufactures, but we certainly can say we probably work with everybody that supplies solutions to the manufacturing and processing industry.

15:18

Craig Resnick: Again, helping them with knowing market sizes, shares, trends and helping them through their strategic planning and product strategy for what the world needs as far as products and solutions. And then the third type of client we work with are the financial analysts. It's the equity analysts that are on the quarterly calls with the CEOs that participate in industrials and helping them formulate when they wanna talk about, for example, Digital Transformation. They wanna know who are some of the leaders in that space and what are they doing? And if they're devoting two cents EPS to Digital Transformation, is that a worthwhile investment or not? So we kinda look at it from all three sides. We just finished doing a Digital Transformation trends presentation a few minutes ago, so I look forward to working with the esteemed panel here and Don so.

16:11

Don Pearson: Thanks, Craig. Jean-Paul.

16:14

Jean-Paul Moniz: So it's Jean-Paul Moniz. I work for Cameco Fuel Manufacturing. Sorry, not Engineering. But we're a Canadian supplier of CANDU fuel bundles for the Canadian nuclear industry. We supply the… I think it's the North America's largest reactor fleet in Bruce Power. And so I've been an active Ignition user since about day one. 2010 was, I think when we first bought, talking with Melanie, I think we're customer number 100, but we have two manufacturing facilities to manufacture CANDU fuel. We're full stack Ignition and Sepasoft in both plants with an enterprise broker. Tomorrow we're doing a presentation with 4IR on “Git Serious” and deploying Ignition up in the cloud for dev and QA environments. A lot of our work right now is focused on finishing off our MES implementation for full-stack traceability on our manufacturing components and then also working towards that single pane of glass view for frontline and line users.

17:25

Don Pearson: Good, thanks for being here. Nathan.

17:29

Nathan Elmore: Yeah, thank you for Inductive Automation for having me. Yeah, I've worked in a couple of different industries. Currently, at Walmart, in supply chain, I've worked in automotive and food as well. What we work on at Walmart is specifically giving more visibility into our buildings on the back-end of our warehousing and supply chain, even providing that at the associate level and then all the way up to the CEO level, where we're working and moving our information from the warehouse to make it actual data into the cloud formation and an enterprise solution.

18:01

Don Pearson: Good. Thanks. I think this group can probably see from the introductions here that we probably have a few people who could answer some questions you may have. I'm gonna open with one and then I can... It's kind of bright up there, so I can’t actually see everybody, so you'll have to then see if... Raise your hand or something and grab a mic and then say something if I don't see your hand. I can't see hands up there, but I think I could probably see them down here. But I'll start with just a general... And everyone doesn't have to answer this, but some of you probably there will be an answer to it. What really got you started on, if you could call it a "Digital Transformation journey," what was it that got you, your company, your organization, started on that journey? Or if it happens to be you personally or professionally. What got you started on that? So Dan.

18:51

Dan Stauft: Yeah, so as I said earlier, my whole career in automotive was data-driven, and that was kind of how I thought all manufacturing was. I had no idea that I was spoiled rotten in the automotive industry. And when I joined SugarCreek, we have some really, really cool technology on the floor in islands. For example, we've got these slicers that have vision systems on them that adjust bacon thickness to get the right weight after a microwave oven. And great technology. They were plugged into the ethernet, and they were talking to nothing.

19:25

Dan Stauft: So there was absolutely no data being used at these amazing million-and-a-half-dollar machines. And when I looked around the company, I noticed that that was pretty much the norm. We had a ton of great equipment that wasn't talking. So when I pulled the trigger on trying to replicate it at an automotive assembly plant, I did it using the Ignition trial. I downloaded the trial. I'd never used Ignition before. My background was simplicity in Wonderware. And I modeled a microwave oven line that's a high-volume, pre-cooked bacon facility just to prove what it could do. I had the Sepasoft MES components in it, and I basically walked up to the owner... I'm lucky. The owner of my company, there's only one guy. He's the single stockholder. So if he likes something, it gets ramrodded, basically, through the process.

20:24

Dan Stauft: So I showed him this one area of one of our six plants, and I said, "This is what I can give you, and this is the price tag that it's gonna be." And John nodded his head. The PO was written within two hours of “corporate approval,” which is... It would've taken me probably two years at General Motors to get something like that through. And we implemented it based on pain points. The first line that we went full throttle on was a problem child line, and we fixed the problems. And as we rolled this out, we also rolled in a corporate continuous improvement team because data by itself doesn't fix it. If you suck and you connect the machines, they just show that you suck.

21:08

Dan Stauft: And if you don't do anything, then you continue to suck, but now everybody knows you suck in real time.

21:15

Ravi Subramanyan: But at least you know that you suck.

21:24

Dan Stauft: So data doesn't do anything by itself. You need to bring in a culture of continuous improvement, and you need to have a strategy for what you're gonna do with the data, and we were lacking that. Luckily, we hired a couple of other guys from outside of SugarCreek that were used to that environment. Toyota-type guys in ConAgra. And we built a corporate continuous improvement team. And every single plant, within six months of putting Ignition online, we had at least a 50% OEE improvement. Every one of our plants has more than doubled as we've progressed. Right now, we're at the point where to get gains are requiring engineering resources because all the low-hanging fruit is gone. And we've got... Everybody in our company is 100% focused on Ignition, empowered workers on the floor. It's completely changed the culture of the company.

22:19

Don Pearson: Cool. So thanks. Anybody else wanna comment on it? Yeah, Ravi.

22:21

Ravi Subramanyan: I can talk to it from an OEM perspective. Like talking to companies and other customers that are on this journey. So, obviously, we talk to companies about their Digital Transformation journey, factory modernization, how they would like to do it, what sort of technologies they want to use. Pre-COVID, it would obviously have taken a long time for them to take the move. I think COVID, in some ways, yes, it was negative in a lot of ways, but at least from a Digital Transformation perspective, it really made people wake up. You know what? We are losing money. Supply chains are strained. Regulatory compliance needs are hitting over the roof, and we are still managing things with paper. At least we should digitize it so we can actually automate some of our processes, make sure we're able to handle some of the near-term needs. That's really helped companies just jump ship and get into it.

23:16

Ravi Subramanyan: One thing that Dan mentioned, which was really important, is the culture, right? Prior to this, the reason why the Digital Transformation initiatives were stalled is because the company culture wasn't quite there. They didn't see the need to do it. "If it ain't broken, let's not fix it" was the attitude that a lot of people showed around different industries, but now, they realize that if they don't do it, they don't have a future. So the culture, that created a cultural transformation, which made Digital Transformation much easier because when it comes top-down, it really is something that people will adopt. So I just wanted to add that perspective.

23:54

Don Pearson: That's a good perspective. Someone else? Yeah, go ahead, Jean, jump in.

23:58

Jean-Paul Moniz: I think from my perspective, I like to... To me, I kinda hate the word “Digital Transformation” because, from my perspective, it's more of a Digital Evolution. You know what I mean? You sit there... And we've spent the last 15 years automating our processes, and so with the goal of automation. But then, as technology evolves and as new use cases show up after you go through the automation of the process, and then you're sitting there looking for your next gain, whether it's through continuous improvement or other means or whatnot. You're looking for the next opportunity to sit there and find an advantage and whatnot. And to me, I look at it with the lens of evolution. Some of the things that we're doing now, we couldn't do 20 years ago, but then I sit there and look back, like Dan, I spent some time in automotive too, and we were doing aisle in-line vehicle sequencing back in the early 2000s. So to me, I look at it as more as an evolution and sort of technology adoption. And then I sort of throw on the lens of technology adoption curves, and that sort of explains how we have some of this disparity in the industry where you have some industry leaders out there doing all the right things. And then you got a lot of laggards out there that are sitting there just trying to figure out what to do.

25:15

Don Pearson: Sure. Anybody else wanna make any comment on that? Craig?

25:19

Craig Resnick: Well, it's interesting because when it comes to being technology leaders and laggards, when we work with clients, we're very involved with the old path initiative for Open Process, use like Open Process Control. And ExxonMobil wants to take a leadership position, but when we work with the other oil companies, everybody wants to be number two, but they're afraid to be number one because they want somebody else to kinda be that pioneer, make the mistakes, and then they'll learn from it. And one of the things that we try to advise clients with this whole... And then I agree with the Digital Evolution, of course, and the Digital Transformation. What we try to advise is you can't be this timid because sometimes what inaction does is you're like the deer in the headlights, and you get run over. And you think you're being careful, but you're not.

26:15

Craig Resnick: The idea is you really need to look at these technologies. And when companies kinda get resistant, we say, "Okay, let's start with a clean sheet of paper. Let's do the low-hanging fruit strategy. Forget the... Let's not talk about I4.0 or IoT. What's your problem?" The problem is, "Okay, we have unscheduled downtime on this line." "Okay. What can we do to rectify that? Is it something... Can we do a better job of as far as predicting failure of an asset? Can we do a better job as far as being able to schedule maintenance? Can we do a better job of making sure the right material is in the plant at the right time?" So now it's more of a scheduled maintenance downtime to fix something rather than now screwing up your entire production. So what we try to say is instead of getting all wrapped up around the axle with the buzzwords, and I guess as the analysts, we're guilty as anybody of acronyms and trying to confuse people with buzzwords, but let's focus in on, "Okay, what's your issue?" "My issue is my OEE is off by 2%. What can I do to raise my OEE?" And do those block and tackle things. And then all of a sudden, they've started to progress on their Digital Evolution or Digital Transformation, and they don't even realize it.

27:27

Ravi Subramanyan: Right.

27:27

Dan Stauft: Yeah.

27:27

Don Pearson: A good point.

27:29

Remus Pop: I think I can tie in a little bit to what both Craig and Ravi said. I remember sitting on a pitch last year before I joined AWS talking to a client that was looking to do an OEE project, and he asked me the question, "What's my ROI gonna be if I implement OEE?" And I looked at him a little silly, and I said, "Well, that's entirely up to you. We can give you all the best tools and data in the world, but if you don't teach your..." Like what Ravi said, “If you don't teach the culture in the organization how to use that data and the business how to benefit from that data, it kinda falls flat.” So I think there's been a lot of discussion around that, like Craig said, with the buzzwords and everything, but, ultimately, we're trying to deliver business value. And as long as we keep focused on the problems that we're trying to solve, I think that's the right way to go about it.

28:10

Don Pearson: Sure. So I'm gonna look out here and see if there is somebody ready to ask a question that has a microphone in their hand. Is that true? If not, you can go ahead and raise your hand, and we'll bring you a microphone. And I'll ask another one. It may be the case that Digital Transformation has a lot of different terms that could be applied to it, to your point that you just made, Jean-Paul. So in your particular industry, do you see unique challenges? I don't know. Keith, when you look at Blentech, did you see unique challenges to get on some sort of an evolution/transformation journey, particular to your industry?

28:55

Keith Weerts: Well, I don't know if it's particular to the food industry, but I think every industry is difficult. I don't know, but the food industry seems to be fairly slow-progressing compared to the mining industry, the oil and gas industry is very fast to adopt things. Food industry was difficult. I have been working with the food industry off and on for 20 years, and I felt like it's just like moving through molasses.

29:22

Keith Weerts: And so it's finally... We're finally making progress. And I think, like you said, with COVID, that did make a difference. What we sell nowadays is not so much machines, it's capacity. And so when we can go to people and say, "Listen, we can increase your capacity by helping you with your data. Look at your data. You can actually… don't have to buy a machine from us, buy capacity from us." And that's a mindset that takes a while to teach, but once you get that message across, it becomes a lot easier sale. Then they begin to trust you. There's an awful lot of trust that you have to build with customers when you're working with this type of data. They need to know that you're responsible, that you're taking care with their data, that you're not just trying to sell them on another whiz-bang tool. There is a lot of faith that needs to be built. It's different when you're within a company. Although Dan had to do the same thing, he had to convince his owner that they were committed to this. And we have to do it with our customers out in the wild and can show them that we're reliable partners.

30:27

Don Pearson: Okay. Good point.

30:28

Dan Stauft: I’m dovetailing with that.

30:30

Don Pearson: What's that?

30:32

Dan Stauft: Our biggest challenge. I'm gonna dovetail on that because he dragged me into this.

30:35

Dan Stauft: So I'm gonna go.

30:36

Keith Weerts: Easy, easy.

30:37

Dan Stauft: Alright, I'm gonna go.

30:39

Dan Stauft: The easy part was getting John to say, "Yes, I want it." And saying, "Go forth and prosper." The harder thing was the actual implementation because the food, especially... We're a meat packer. It's not a glorified job. If you look at automotive industry, they've got the highest-skilled workforce, probably outside of some of the other tech fields, but we don't have rocket scientists slinging pork bellies around a plant. So getting them on board... Because if you don't have the plant floor engaged in the data, in the problem-solving activities, you're not gonna get anywhere. The CEO can't do it. He's not gonna go down and train somebody on how to use a Multivac or a Blentech or something like that. So you have to get the people on the floor. And our challenge was convincing them that we weren't going to use the data to beat 'em up.

31:31

Dan Stauft: The first thing we did is we put these huge dashboards up that showed them where they were, and their reaction, from the Plant Manager down, was, "Oh, shit" because the numbers weren't good. But we had to teach them, "We don't have a target number. We just want you to get better. And we're gonna use your input to allow us to identify the opportunities to get better." And I'll give you an example where we had a 40% improvement on the line like that. We set theoretical maximums for our OEE targets, and that was, basically, whatever the bottleneck on a line was. As fast as it could run, that was our theoretical maximum for a given product. And we're running this line that's packaging meatballs, and we were running it at six cycles a minute, where the machine was capable at 10 cycles a minute. We went down to the floor, and we asked the operator why we're running at six cycles a minute. He goes, "Well, we always run it at six cycles a minute." Like, "Well, can you try to turning it up to 10?" And they're like, "Sure. Turn it up to 10." Boom! Step increase.

32:31

Don Pearson: Okay.

32:33

Ravi Subramanyan: This is how we've been doing it forever, we just do it.

32:36

Dan Stauft: That's correct. It's amazing when you get people thinking outside of their comfort zone what they've always been told. We blew all our bill of materials away because they were all wrong because they were based on tribal knowledge that was incorrect.

32:50

Don Pearson: Yeah, thanks. So back over... You started to say something, Nathan, in terms of unique to your industry and challenges.

32:56

Nathan Elmore: Yeah, I don't think it's gonna be unique to my industry at all, but the hardware exactly that we had in the buildings and thing pre-determined before the Digital Transformation really occurred was, what do we do with that hardware, that technology that's no longer useful because it's not giving us information that we need? Or do we scrap it at that cost, or do we pay to upgrade and update it to actually get that Digital Transformation? To really root it out and then move forward was one of the biggest things that we had to work through.

33:25

Don Pearson: Well, that's good. Thank you. Anybody else wanna comment on that?

33:29

Ravi Subramanyan: I just wanted to comment on the food industry. What I've seen is that, at least with some of the customers that we see, there is a heavy need for innovation because... Be it the packaging or the content. Because today's consumers, they want to consume more healthy food. Healthy food or healthy drinks. And so they're very conscious on the ingredients and the calorie count or the content and things like that. So given that, I think there is a need to innovate on packaging, innovate on how quickly you can bring some of those products. And you have those nimble, new manufacturers that come in with that whole digital mindset, if you will, that can turn things around so quickly. So the big players need to actually be able to change themselves quickly, to change their lines to be able to meet the demand.

34:16

Don Pearson: Sure.

34:17

Ravi Subramanyan: So it will be easier for them.

34:19

Don Pearson: So I wanted... Anyone else wanna comment on that before I move on to the next question?

34:22

Craig Resnick: It's culture.

34:23

Don Pearson: Culture, yeah.

34:24

Craig Resnick: We'll go into plants, and you'll have an operator that'll tell us, "Listen, if we're doing an OEE project, for example, if you put it up on display and it shows how bad I am, I'm gonna lose my job. So, therefore, I don't want it visible." You need is the top-down has to be, "We're not here to measure you as you are today. We're trying to measure you where we can get you, where you can evolve to. You're part of the solution. You're not part of the problem." And the idea is, is that if you work with people on the ground rather than just a memo to say that some... That we're gonna be putting in the system, speak with the people first, get their opinion, and ask them for input because now you've empowered them. You've now... Now they're part of that solution, and they feel like the solution is gonna help them produce better, not that this is just gonna be some measuring stick as an excuse to get rid of people.

35:15

Don Pearson: Sure. Good point.

35:18

Keith Weerts: Just wanted to...

35:18

Don Pearson: Keith you wanted to say something else.

35:19

Keith Weerts: I don't know if you've noticed in our conversation, none of us are saying anything about how difficult it is to move the data.

35:25

Don Pearson: Right.

35:26

Keith Weerts: It's simple to move the data. It's getting them to use the data.

35:30

Keith Weerts: And that is the challenge that I think we all face.

35:34

Don Pearson: Sure.

35:34

Ravi Subramanyan: Exactly.

35:36

Don Pearson: So tangential question to the one that you mentioned earlier about the change due to COVID having an impact on maybe motivating people to move faster on some of these initiatives, if you will, for either evolution or transformation whatever. So on the downside of that, obviously, there's things going on in the world that make supply chain a challenge. It's not just coming back together nicely. So how do you deal with that piece of it as regards continuing to move forward when you gotta have hardware? You gotta have stuff to make it work. Anybody? First comment on that? Yeah, go ahead.

36:10

Nathan Elmore: I can go ahead. I would say being proactive as being key, especially on the hardware front. We've seen lead times up to 13 months. And especially during COVID, you're having to pivot and be so adaptable so quickly that it's really hard to actually do. And then also you have the actual integration installation. There's huge demand in our industry of supply chain for all of the things that we were doing. We really had to work on the labor market as well, which was a huge issue because how do you supply the people to actually do the Digital Transformation?

36:44

Don Pearson: So have... Is it getting any better? The 13-month may be extreme. Is there something happening that makes you positive or negative or just the same in terms of optimism on that?

36:57

Nathan Elmore: I think it's a hit or miss. There's areas that's definitely gotten better. We're not seeing lead times like that and things, but there's definitely areas where it's still just as bad. So we still have to be just as proactive as we were two years ago.

37:09

Don Pearson: Okay, thanks. Yeah.

37:10

Remus Pop: One of the interesting things that has happened is the wide influx of these new hardware solutions to provide the typical type of data we would expect from a PLC, or a DCS, or SCADA system. I think, obviously, it's seen out here. I've seen a couple of vendors, but I think one of the very interesting things, and I think it's a lot of it driven by COVID and the supply-chain problem, is there's now a tremendous number of options you have to gather data from equipment. Typically, if you were to ask me two years ago, I would have said the goal and the focus is always gonna be to get as much data directly out of the controller as we possibly can. I think what COVID did, and what some of the other things did, is that now we wanna go for a little bit faster, a little bit quicker wins to get to that level of visibility that we would normally get. And we're willing to sacrifice some of the data to get to some meaningful KPIs. We want metrics that we can start to improve on to bridge the gap.

37:58

Remus Pop: And I think when we see that, obviously. And I think the supply-chain shortage definitely impacts that with just the wide variety of hardware options that are now available to help us get there.

38:08

Don Pearson: Thanks, Remus. Yes, Ravi.

38:12

Ravi Subramanyan: So what we've noticed is prior to COVID, I think especially in pharma, I think supply chain, they felt was pretty strong because they knew exactly what the demand was, and who the suppliers they had to work with, what are the different pieces of information they needed. There were like supply-chain islands, as I saw it, where they're just concerned about their chain of command, and they were very well versed with that. With COVID, all these things got tossed. And I think it's not just a primary supply, everybody was gone. So when that happens, you have to have a global view of your data because, obviously, in this world, nothing comes from one location. There is so many repercussions to the thing that you're producing that has like different parts of the world that needs to come together.

39:02

Ravi Subramanyan: So the globalization of supply chain is what has really started post-COVID, and for that to happen, you're obviously a machine data from your DCS control system needs to come together along with like your supply-chain data, maybe your shipping information or other pieces of information that are part of your supply chain, all that needs to come together to give you that full picture, not only at a local level but at a global level as well. And that has really helped our companies to transform themselves quickly and be able to meet the supply of the demand.

39:34

Don Pearson: Dan.

39:35

Dan Stauft: Quick example this is one of the things that, to us, COVID was actually kinda helped us... When I say us, I mean the OT team. We've been at war with our controls engineers, who are in a different department, 'cause we did Ignition backwards than most people. We went full-blown SCADA/MES and didn't even think about doing HMIs. But we're trying to get after we see how easy it is where we can go to our controls group and say, "Well, why don't we just start doing Ignition HMIs." They're like, "Rockwell, Rockwell, Rockwell." So earlier this year, we had this huge project, and one of the lead controls engineers comes up to me, and he goes, "Man, we can't get PanelViews." I was like, "Huh." He goes, "Do you know if we have any old PanelViews laying around?" I was like, "Let me tell you something Rick. What we can do is we can get four IP69s, 17-inch panels, running Ignition Edge for the price of one PanelView, and we can get them tomorrow." And he's like, "I don't know. It's a hard..." So we're getting them… COVID is kind of forcing them out of their comfort zone, which we're like, “Yay,” but...

40:50

Keith Weerts: Okay, I have to add to that too because as an OEM, we're building panels for people all the time, and we have to tell them anymore, “You can't have Allen Bradley.” We're down to the only Allen Bradley part in our panel is a PLC, and that's going pretty soon too.

41:08

Don Pearson: Wow.

41:08

Ravi Subramanyan: It was interesting. I was at the IMTS last week in Chicago. And the people that... The big players are the ones that had big supply-chain issues. The nimble players, they said, "Hey, we have supply for the next six months. Just bring it on. Tell me what you want." Right, so somehow they have been able to figure out and take care of the supply chain. It's the big ones that are like Rockwells that are having issues.

41:30

Don Pearson: Yes, go ahead.

41:32

Jean-Paul Moniz: I mean, to hit on what Dan said, sometimes I think... And I was gonna sit there and talk about sort of IT/OT convergence, but I think some of that lies at the foot of OT people, and I've been one of them. We migrated off of PanelView HMIs a long time ago and exclusively use Ignition as our HMI, so we just use plain Jane Windows, touch screen, or whatever. But it's using those type of tools to sit there and mitigate issues like this, and sometimes I think the OT group has a responsibility to sit there and say, "Get the concrete shoes off and starting thinking a little bit more forward or whatever." And some people sit there and say, "Oh, the performance isn't there." Or whatever, and it's like, I used to think the same thing until we sat there into the whole manufacturing line and put it on Ignition. I was like, wait a minute, this things, we haven't had an issue with it, and I would sit there and say, “Five years.”

42:28

Don Pearson: Thanks. Craig.

42:32

Craig Resnick: Well, I think what also happened during the pandemic is we would have people that would say that the pre-pandemic, but this data is not leaving the plant, like you'd be in the process control room, and this data stays here. And then when that workforce wasn't in the plant, and that workforce is at home, now they need remote licenses, and all of a sudden they're breaking all the rules for allowing remote data to be at least monitored outside the plant and sometimes even controlled outside the plant. And that's something we would never have seen without the pandemic. The other thing we've seen is that people would say, “You need to have that industrially hardened PanelView,” for example, something that's NEMA IEC rated for shock and vibration, dust, water, moisture, and then all of a sudden you see people walking around with their iPads looking at... Which obviously isn't gonna quite survive the vibration and the shock and what have you from that you're gonna have certainly from an industrially hardened device, and they found that maybe this $1,500 iPad, if it breaks, I'll just buy another one. Instead of buying one that I got to amortize over 10 years, and all of a sudden, it's still running like an 8086 microprocessor because it hasn't been paid for yet and running Windows 2000 or something along the...

43:52

Don Pearson: Yeah.

43:52

Craig Resnick: So that's what has changed, is the ability to get data outside the plant that wouldn't have happened before and use more commercially available devices rather than industrial devices.

44:04

Don Pearson: Sure. You wanna add to that?

44:05

Jean-Paul Moniz: I mean, he's bringing up a great point too. And especially in the OT space, we've been used to hardware platforms that have 20-year life cycles. And if there's anything that COVID has done, it has shown us that that's not happening anymore, you take a look at, you know, I'll point the Rockwell or whatever product catalogs that... Forget Silver series. They're just gone, like sorry, you're not seeing them anymore. And that's the way the industry is going. You're gonna see a lot of these life cycles shorten up or whatever, and you're gonna design for something that, if you're lucky, hopefully, you'll have a five-year useful life... Technology is changing quick, so I think the best thing you can do is sit there and strategize about what your architectures look like and what you're using, so you can sit there and insulate yourself from that and just swap out components at will.

44:57

Don Pearson: Sure, good point. We have a question here. Go ahead.

45:01

Audience Member 1: Hi. As a systems integrator, the other thing that happened with COVID is kind of the great carousel and the great exit. So you guys are talking about a culture of resistance. I'm actually not seeing that so much. More of what I'm seeing is I'm walking into plants, and they don't know what they don't know what they don't know. All that brain knowledge is gone, and now I'm walking in, and people don't even know what they need to be looking for. So could you guys speak to that some? Thank you.

45:35

Dan Stauft: I think the issue from that perspective is, I think that's a good thing 'cause it got rid of the guys that didn't wanna change. Seriously, I think...

45:48

Dan Stauft: The people that fight the most are the people that are ingrained in their ways, and they're like, "We've always done it this way, and we make money." Well, we can try it a new way and make more money. "Well, we've always done it this way, and we make money."

46:00

Ravi Subramanyan: If it ain't broken, don't fix it.

46:01

Dan Stauft: Yeah, if it ain’t broke don’t fix it. So we actually had some, I wouldn't call it forced retirements, but some of our elder workforce no longer works there, and we're getting a lot less pushback from the younger workforce. From a workforce perspective, I'm old. I'm 53.

46:23

Keith Weerts: Hey, hey, take it easy.

46:26

Dan Stauft: But you look at the younger workforce. They're used to technology. I didn't grow up with cell phones. I had a rotary phone. It's easier to sell technical solutions to generations that grew up with the technology that's similar to what we're implementing.

46:45

Don Pearson: Sure. Anyone else want to comment on that? Remus first and then Ravi.

46:47

Remus Pop: I think, to answer the question, I think just focus on the problem. I think what we've talked about a lot here is they obviously have approached you to solve a problem that they're having. I think one of the things we talk a lot about at Amazon is we're customer obsessed. Just be customer obsessed, find out what that problem is that they're trying to solve, and help them solve it. I think if you start there, I think you will naturally see a progression of strategy and other problems that will come up. Once you solve one there is another one, and another one, and another one. So I think just following that methodology will get you a pretty good strategy.

47:16

Don Pearson: Cool, Ravi, your thoughts.

47:19

Ravi Subramanyan: One of the other factors that's, in my opinion, accelerated Digital Transformation is aging workforce. Either forcibly led to retire or just retired. So a lot of the knowledge, the tribal knowledge of the processes and the machines, is going with them. So Digital Transformation is necessary to capture some of that information that they have in their minds and give it to the younger workforce so they know exactly what to do. If this happens, you do this, or if that happens, do this, that kind of a thing. And Digital Transformation, IIoT, AR/VR technology. The augmented reality, virtual reality technologies can help the workers in the factory floor do things that they otherwise wouldn't be able to do.

48:04

Don Pearson: That's a good point. Yes, Jean.

48:08

Jean-Paul Moniz: Yeah, I mean, just to hit on that exact issue. I have a friend of mine that's an executive as a contract manufacturer for consumer goods, and they went through exactly that when COVID hit. And so they made the hard choice to sit there and lay off their workforce, and because their market just went straight down, and when they had to sit there and flex back up, and they went to the workforce, they found out, hey, they're not there anymore. And so now we're sitting there trying to run and operate with a whole bunch of brand new workforce and, to your point, a lot of that old school mentality of having the knowledge hidden back in the back corners and not having it, whether it's documented properly or whatever, is a big issue for a lot of manufacturers right now. And so, to be able... Using the lens of Digital Transformation or whatever you want to use. To Ravi's point, being able to sort of cook in the books what you actually do in the digital systems and provide those tool sets to your workforce to enable them to sit there and do what they need to do to help you be successful. I mean, to me, that's the future.

49:15

Jean-Paul Moniz: When I sit there and make commentary about being able to enable our frontline workforce, that's what it's all about. You sit there, and you take a look at five to ten years out and understand what transformations are going to happen with the workforce alone and what their expectations are going to be. And this old game of go ask Joe in the back because he knows where you need to hit it with a hammer or how to tap dance around the equipment. Those days are gone, right?

49:44

Don Pearson: Yeah, that's a good point. Just we have one more question over there. Question over there, go ahead.

49:50

Audience Member 2: Jean-Paul, you mentioned about the five to ten year looking ahead. Question for the group, what are you excited about for Digital Transformation next two, five, ten years?

50:01

Jean-Paul Moniz: Sorry, can you say that again? I didn't hear the sort of the...

50:03

Don Pearson: Go ahead and repeat the question.

50:04

Audience Member 2: I was just going to say, what are you excited about for Digital Transformation in the next two, five to ten years?

50:12

Jean-Paul Moniz: There's actually a whole bunch of stuff that I'm excited about. The first thing is about just merging the disparate sources. If I sit there and take a lens of an industrial mill rate mechanic, or an electrician, or a frontline worker, it's being able to sit there and amalgamate all their information in the one spot. And stop people from having to go over here, go over there to get their information. And then taking that idea and evolving on top of it, using the technologies of mixed reality, AR, and whatnot, being able to give that immersive experience to extend the functionality of digital technologies for those people to sit there and sort of help them get to solutions quicker, better, faster. You know what I mean? So if I'm an industrial mill rate mechanic and I got called because my line's down, I mean, we've already done the OEE thing, and we already know where the problems are. Now I need to go and fix it. Like at the end of the day, lines go down. You still got to fix them. So how do I get to quicker return and uptime and whatnot?

51:21

Jean-Paul Moniz: And so if this is a mechanic that didn't have the experience of installing the line or the training from the OEM or whatever it may be. How do I get them the information they need to be able to sit there and diagnose the equipment as quick and fast as they can?

51:35

Don Pearson: We've got another question here. Go ahead.

51:38

Audience Member 3: Is this on? Yep. So, Dan, this is from you. This is interesting. You said some of the things you did, and I appreciate your honesty and transparency. As a solution provider. This is Aaron Bolshaw from SafetyChain Software. We often enable real-time data visibility and then trending out of the box. But we get a client that disbelieves what they see in the data. So in your...

52:01

Dan Stauft: Surely not...

52:02

Audience Member 3: That's putting it nicely. They disbelieve... That can't be right. We're running this the absolute best we can, and they truly believe that. So my question is, can you comment on the ways that you showed your team how to use the data for continuous improvement, were there some tactics that you used? Was there some things that you could do that were... That sort of led the horse to water?

52:23

Dan Stauft: Yeah, so the initial... That continuous improvement project we did, we were making a product for a very large retailer, Costco, that we were failing to hit our metrics, so we went in, and we were gonna fix... We're central office. We're here to help. We're gonna flash down to the plant. We're gonna fix all their problems and etcetera. So when we first put OEE on that line, I wanna say it was running like 28%, and the plant manager goes, "No way in hell, we're running better than that because we're within 5% of our standard." "Your standard is wrong." "No, it's not. That's what it was," And we got the same pushback.

53:03

Dan Stauft: So we said, “Well, give us the best operators you have for that line, so we can teach them how to problem-solve, or we can teach them how to react to the data, and then at the end of the day, hopefully, we'll prove you wrong.” And we were able to basically double the bill of material rate on that line within I wanna say it was four weeks. So as soon as you do the first line and you prove the data is real regardless of what the preconceived notions are of what the data should be, you turn from a push process, where, “We're from central office, and we're here to help,” to a pull process, “I have a problem with another line, can you guys do what you did on that line over on this line?” So as soon as that coin flips you’re golden, as soon as you can prove by giving them value that the data and the processes work. That's the key I believe.

54:04

Don Pearson: It's a good point. Christine, you have a question. We have back there. Go ahead and stand up and speak.

54:11

Audience Member 4: So it's been my experience that when you talk about Digital Transformation to a company, it really depends to whom we are speaking to. Maybe if you're speaking to a line manager, they just want a notification if a part is in defect, and if you speak to the CEO, you would like to see how that translates to maybe preventing a mega recall, and this sort of ties to what Remus mentioned about the ROI. A lot of small and mid-sized companies, since their profit margin is small, they really aren't sure what's the ROI for data transformation. So my question is, how do you find the correct data transformation problem, and how do you sort of prove ROI? Thanks.

54:48

Don Pearson: You wanna take a shot at that?

54:48

Remus Pop: Yeah, I could start. I think the first thing you have to do is measure the process before and after. I think as a manufacturer, whether you're a small mom-and-pop or a large enterprise, you generally know the cost of goods to build your product. I think if you can see that the data is showing you the more product you build, then the more money you make. So I think having measurables along that process is the way to measure your ROI. Without data, you can't do anything. So that kinda drives the idea behind the Digital Transformation, and to the different levels of the organization, you have to almost model a persona for who you're showing the data to. I think one of the key tenets of what we're talking about with Digital Transformation and Industry 4.0 is the idea that we have to deliver the information to the people that can act upon it the fastest. So a line operator, that might be downtime issues or fault metrics or something like that. A maintenance person is gonna be something different than a line supervisor, than a team leader, than a CEO, than a COO. Everybody has different metrics that they're looking for, so I think you have to work that into your solution, is the idea that the persona matters.

55:56

Don Pearson: Go.

55:57

Ravi Subramanyan: Yeah, if I can just add to that. Right, so in the… Identifying the problem is absolutely key, like Remus mentioned. Like, for example, in mining. If your operations… If you have like a downtime that is not predicted, unplanned downtime if you will, it's gonna cost you a million dollars per day to fix it, then obviously that's the ROI. Or, in the oil and gas industry, the safety of your worker there, you want to reduce the number of deaths by one or something. That is an ROI. So those are tangible ROIs. Identifying those things and working towards that is the way you can convince management that this is something that you want to do and adopt it enterprise-wide.

56:35

Don Pearson: Thank you. We got one more question from out there, and then I'm gonna ask a final question. Where is the one? Up over there? Okay, go ahead.

56:43

Audience Member 5: Hey, Don, it’s J.C. I've got a question. You mentioned roadblocks, like the aging workforce, that maybe went away during COVID. As we look, all of us are transforming all of the stuff that we're transforming. How do we ensure that we don't become the next roadblock?

57:04

Keith Weerts: Who is that for?

57:04

Don Pearson: What's that?

57:06

Keith Weerts: Who is that question for?

57:07

Don Pearson: Well, why don't you… You opened your mouth Keith. Why don't you take it, okay?

57:11

Ravi Subramanyan: You open your mouth then you get the question.

57:12

Don Pearson: I think it's for you.

57:13

Keith Weerts: There is… You're right, it's very easy to become that roadblock, but there's so much potential with this data that it just seems to be almost limitless what you can do with it, and it really requires listening and talking to the customer and hearing what they're asking for. And seeing beyond what they're asking for because you gotta remember that they can only see as far as their glasses will let them see. So we have to keep ahead of them always and just keep on helping them see what can be, and it's just been amazing. You can just do so much more when you have this data that you couldn't do before, and I especially look at it from the cloud-based approach where we were talking about digital twins and some of the presentations earlier. Boy, you can't believe what we can do with digital twins. What we'll be able to do to predict and help people produce food at a faster rate in a world that's gonna be short of food very soon is a very important thing.

58:14

Don Pearson: Good point. Yes, Jean-Paul.

58:17

Jean-Paul Moniz: I think the biggest thing, especially for this group and internally, 'cause you sat there and said, and we're the ones sitting there doing the transformation, and whatnot, and then I think I'll pull it from the keynote this morning. There is one thing that I caught on was getting out of the way, getting out of our own way sort of thing. And where I go with that is implementing solutions that keep us aligned with the forward direction instead of implementing solutions that are proprietary or locked off in a corner that nobody understands. You sit there and say, "How does the next generation come through?" Well, they come through understanding common technologies and common platforms. Right?

58:58

Don Pearson: Yeah.

59:00

Jean-Paul Moniz: And so to me, the answer is, keep it simple and don't do complicated black boxes.

59:08

Don Pearson: To my final question. We only have a couple of minutes left, so, I'm not expecting everyone to answer, but this is called the Ignition Community Conference. So this is a little biased question here, but whether you call it Digital Transformation or Digital Evolution or whatever the term is. How has Ignition, if you can think what stands out the most, how has Ignition helped you to progress in that journey that maybe might not have been as easy to do or even possible to do with other technologies? Dan, you got your hand up first. So, I'll let you say it first.

59:40

Dan Stauft: We could not have possibly done everything that we've done on a different platform. If it would have even been possible, it would’ve required multiple platforms with multiple different programming skill sets to enable us to get where we're at because we're not just doing MES. We're doing app development. We're doing the web dev stuff. It's got nothing to do with the original scope of our project. We just do it because we can. I don't think there's anything else like it on the market.

01:00:12

Don Pearson: Okay. Anybody else? Yeah, go ahead. We’ll start on this end. Go ahead, Nathan.

01:00:15

Nathan Elmore: Yeah, I'd have to say the universal platform and the unlimited licenses is absolutely key. Working a network as big as ours, we've had to go and work with so many integrators, so many different types of equipment and communication and everything like that, that the universal platform has been absolutely essential. And then, to really accomplish a Digital Transformation, other platforms that we had used had limitations of how many people or what could be done. And now we can give it to everybody in the network. Everybody from the lowest level all the way up to the CEO.

01:00:47

Don Pearson: That's great. Appreciate that. Okay, Ravi, your answer.

01:00:49

Ravi Subramanyan: It was well put in the keynote. It's not just about a SCADA system. It's about a digital journey. It's about a digital platform that Ignition provides. That allows people to develop applications to develop solutions that will help the customer. So Ignition has provided the platform that allows people to think outside the box and solve problems that in the past could not be solved.

01:01:13

Don Pearson: Cool.

01:01:14

Remus Pop: I think too...

01:01:15

Don Pearson: Yes.

01:01:15

Remus Pop: I'll be really quick. For me, it was the barrier to entry. It removed that barrier. I didn't have to spend $100,000 on a software product to begin doing Digital Transformation. It was there, it was free to download, and you could just get it.

01:01:29

Don Pearson: Any others? Anything you wanted to say, Keith, and then I'll go to you Jean-Paul.

01:01:34

Keith Weerts: I will tell you that’s how I got into Ignition. So, in 2010, like a lot of the other people in here, it was easy to do. I was battling Rockwell Historian, couldn't stand it, and I found this tool, and I said, "Wow! This is great." And it didn't take me any money to try it out. And then I went to the customer and said, "You should do this." And they said, "Yeah, we'll do it." And that was it. It was so easy to get started, just like Dan had with his management.

01:02:00

Dan Stauft: So why don’t you at Blentech have PanelViews on them that we've got?

01:02:03

Keith Weerts: Because I didn't join them until 2007.

01:02:05

Don Pearson: So that's good. Keith, I appreciate it. I just wanna say a shout-out to our CEO, Steve Hechtman who wanted something that was easy, fun, and affordable. So you found that to be true. That's good. Alright, anybody else? Yeah. Jean-Paul, you had your hand up.

01:02:19

Jean-Paul Moniz: I think it's more of the same. When I started looking at Ignition in 2010, we were sitting there doing really stupid things. I'll date myself, but we were pulling, using DDE to do OEE calculations in Excel and whatnot. But when we came across Ignition and saw what it could do, I quickly developed an OEE app, and that sold it right then and there. There hasn't been an application that we haven't come across that we can't do in Ignition. And then, I remember when Steve came out with it. Maybe I don't know, four years ago or whatever. About the whole not so much... We're not a SCADA platform, we’re an application development platform. And that's the way I look at it. SCADA is probably the last use case on our list.

01:03:03

Don Pearson: On your list. Yeah. Any final statements at all? We've come to the end of our time. And I say that let's give an acknowledgement to our panel for a great discussion.

01:03:20

Don Pearson: So, thanks to all of you. I believe that concludes... You can sort of punch out now and head over to... I think we're heading over to our offices for some food trucks. And let's have a beer. Thanks for a great day.

01:03:39

Announcer: That ends our conference sessions for the day. Dinner will be hosted this evening at Inductive Automation…

Want to stay up-to-date with us?

Sign up for our weekly News Feed.