Innovation-Powered Manufacturing

Disruptive Technologies, Cross-Pollination and Ignition

20 minute read Download PDF

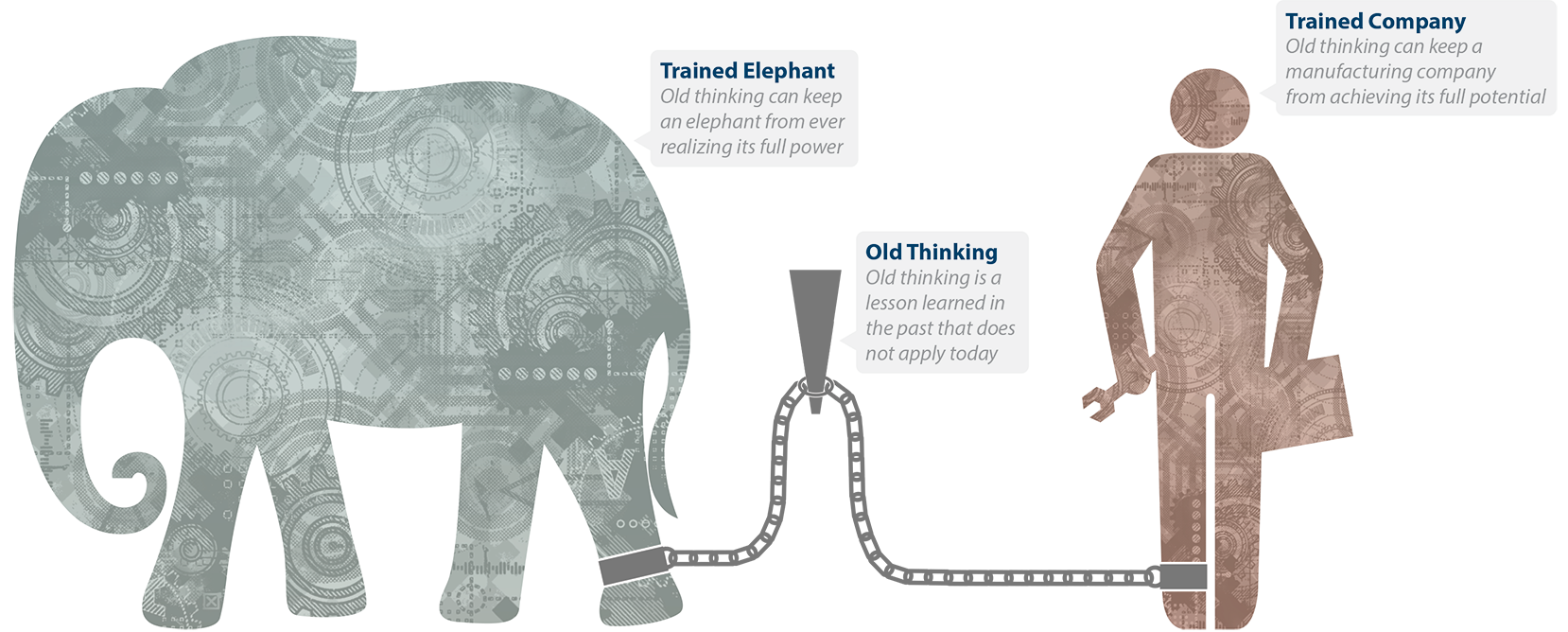

A full-grown elephant can weigh 13,000 pounds and has been known to carry close to its own weight on its back, yet these powerful animals can be trained to stand still.

Training starts when the elephant is young. Elephant trainers use a technique of chaining a young elephant’s foot to a heavy stake that is driven into the ground. When the little elephant tries to walk too far or escape the chain, its foot is yanked back. The elephant learns a painful, lasting lesson: if the chain is on its foot and it tries to move outside of a limited area, it will feel pain.

As the elephant grows bigger and stronger, the secret to keeping it from breaking its bonds isn’t to use a heavier chain but to simply take the stake out of the ground. Because “an elephant never forgets,” a trained adult elephant will stay in place if it has a chain or rope around its foot, even though it has grown strong enough to break free. The stake only exists in the elephant’s mind: all that holds it back are its beliefs based on past experiences.

Is Your Company Behaving Like a Trained Elephant?

Many companies in today’s fast-changing world are like trained elephants: They have been conditioned to resist change by past experiences or outdated ideas about technology.

Perhaps these companies tried to innovate in the past and failed, or they adopted some technology that later fell into obscurity or just didn’t produce the returns they’d hoped for. Leaders of some companies may still perceive the early adoption of new technology as being too trendy, too risky or an unnecessary luxury.

Whatever the reason may be, companies like these are not moving forward even though competitors who embrace the rapid changes in technology are leaving them farther and farther behind. They are unaware of, or unwilling to tap into, the innovative power they possess.

Like a trained elephant stuck in the thinking of its infancy, they remain chained to a 20th century mentality in the 21st century. Companies that remain resistant to change will never reach their full potential and will find it harder and harder to adapt to an industry that is rapidly changing under their feet.

Technology and Risk in the 21st Century

In the 20th century, when the market environment was relatively static, it was more reasonable to take a conservative approach to IT matters. At that time the pace of technological change was slower than it is today, so following a model of slow technology adoption was less costly and still allowed many companies to stay competitive.

The manufacturing industry in particular has tended to run its legacy systems down to their last legs, upgrading only when absolutely necessary. Today, many plant floors are still running on 1990s technology – and manufacturers are spending a lot to keep those aging systems running when they could be innovating. This is a serious problem because the rate of technological advancement has increased dramatically since manufacturers installed those 90s systems.

In a short amount of time, the correlation between technology leadership and business risk has shifted. The greatest risk is not trying to innovate too quickly; it lies in not innovating quickly enough. Companies that fail to realize this in time will be outmaneuvered in the marketplace, and may find they are unable to catch up.

In the 21st century, being innovation-focused is not just a way for companies to project a more prestigious image or chalk up modest gains in efficiency. Innovation is now a matter of business survival.

Disruptive Technology: A Catalyst for Change

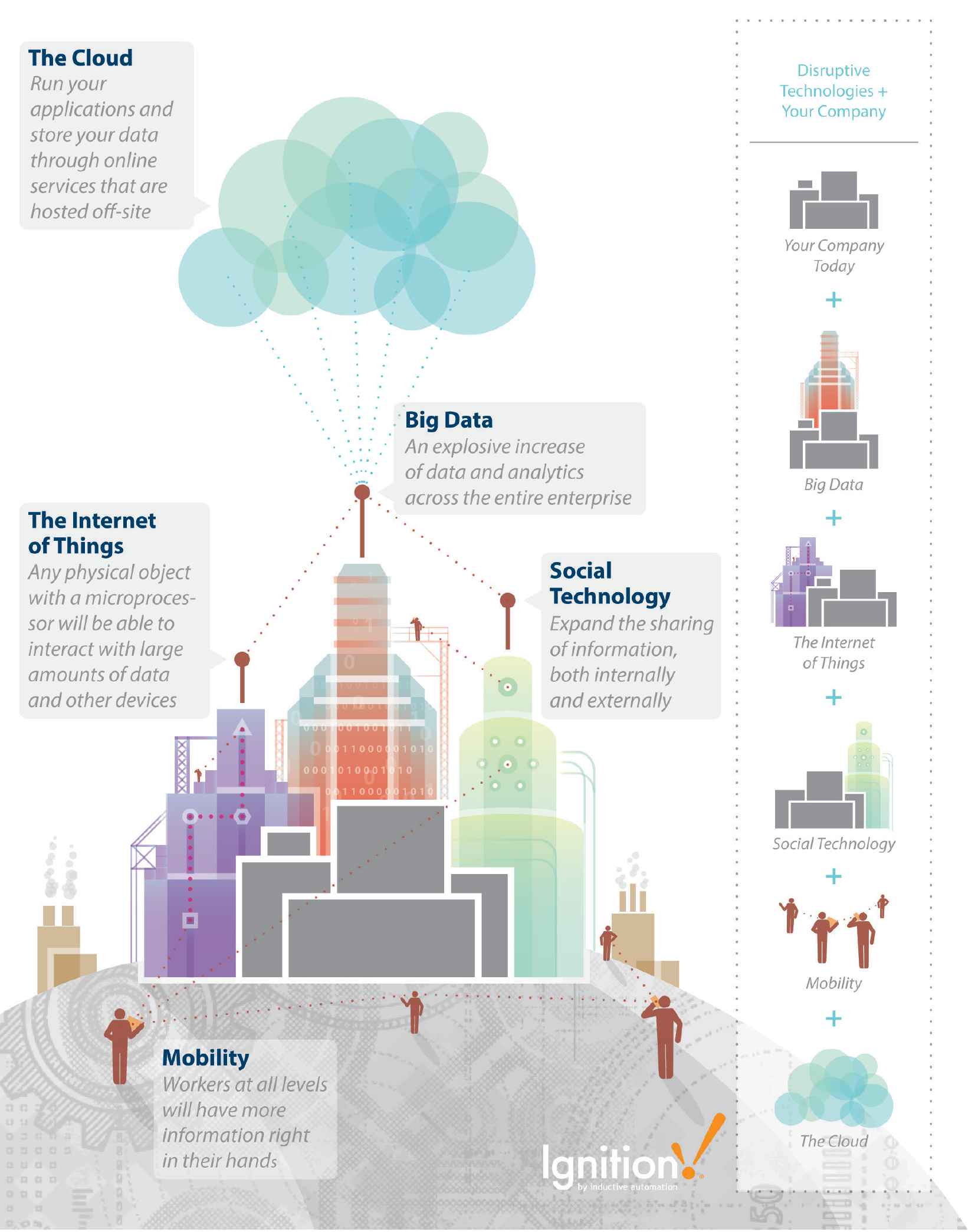

Why is technology changing business so much, so quickly? Obviously, the explosive growth of the Internet and mobile devices over the last 10 to 15 years has profoundly changed the way people live and work. But even more revolutionary changes are on the way, thanks to what the intelligentsia has labeled as “disruptive technologies.”

The term “disruptive technologies” refers to a group of separate but related developments that will change business and society in general. Whether the net effect of those disruptions is positive or negative will depend largely on how a business reacts to them. As the ARC Advisory Group pointed out in its 2013 white paper, “Information-Driven Manufacturing,” disruptive technologies are likely to significantly change the manufacturing business, and manufacturers should therefore take a 21st century approach to technology adoption.

The following are considered disruptive technologies and are on the rise. While these technologies are corollaries to the manufacturing industry and may not have an immediately apparent application to your business, keep in mind that they may be applied to manufacturing in ways that no one has foreseen yet. Even if disruptive technologies don’t directly affect the manufacturing industry, they could have an indirect but very real impact on it by affecting other related industries. Therefore, it is critically important to be aware of these trends and their potential impact.

Big Data

The term Big Data is an inescapable buzzword which describes the explosive increase of incoming data from a growing number of computing devices. More specifically, it describes the increasing volume, variety and velocity of data, which are sometimes referred as the “3 Vs.” How much more data are we talking about? Hundreds to thousands of times more data than most companies are used to handling.

The conventional data tools most companies have now aren’t up to the task of managing, storing and analyzing Big Data. The data deluge may lead to wider use of non-relational databases like NoSQL, which are made to handle larger volumes of loosely structured data and can utilize inexpensive Cloud-based storage and processing.

However, the greatest challenge and opportunity of Big Data is not in its volume but in making it into actionable information. The companies that most quickly convert Big Data into valuable insights will be at a huge advantage. For example, manufacturers could use it to predict changes in the economy, regulations and consumer behavior and then respond to them more quickly.

The Cloud

Cloud computing, or The Cloud, is another buzzword that’s always in the air lately. Using The Cloud basically means that a company is running applications and storing data through online services that are hosted off-site instead of on their own hard drives and servers. Compared to a traditional IT network, Cloud-based computing solutions are more on demand and elastic, which makes them easier to scale and less expensive. Companies can use a public cloud, where services are available to anyone, or a private cloud where services are only available to a limited group, such as their own employees.

Many observers predict that the scalability and elasticity of The Cloud make it inevitable that most manufacturers will move to it, although some businesses may hold out because of concerns that their electronically transmitted data might be monitored by government agencies. A widespread move to The Cloud would have a major impact on the IT landscape as we know it. Manufacturers using The Cloud would benefit by not having to store their own data, do their own analytics or deal with constant software upkeep. Instead, they could pay for their computing needs as they go. As with Big Data, The Cloud helps manufacturers respond to changes in the supply chain and in customer behavior.

The Internet of Things

This term means that “things” (computers, devices, applications or any other physical object with a microprocessor) will be able to collect large amounts of data from the physical world through sensors, and will be able to connect with each other, thereby bringing a new level of automation into business as well as everyday living. This is also referred to as machine-to-machine (M2M) technology

The Internet of Things is thought by many analysts to be the catalyst of a “fourth industrial revolution” or “Industry 4.0.” What might this information-driven industrial revolution look like? Manufacturing will likely become more networked and decentralized, with every part of the process being linked together, even between multiple factories in different regions and countries. Logistics will be more important than ever, as a huge amount of materials and data are synchronized through a complex global supply chain. Data will be the driver through the entire process: even raw materials may be bundled with the information about what product it will be made into and when it will be made.

Mobility

Mobile devices will continue to become prevalent in the workplace. Workers at all levels will have more information right in their hands, and they will be expected to be able to connect with the workplace when not physically present. More companies are adopting bring-your-own-device (BYOD) policies that allow employees to use their own laptops, tablets and smartphones at work and to connect with the corporate network. This is a Cloud-friendly approach that unlocks greater productivity and potential cost savings (compared with buying a tablet for every employee, for instance).

Social Technologies

Connected to the mobility trend is that of workers using unified communications tools (such as instant messaging, videoconferencing and VoIP) and social platforms to expand the sharing of information, both internally and externally. Social technologies give employees the ability to quickly find expertise inside and outside their department or company, look up information, collaborate and solve problems.

Perhaps conflating social technologies with social media, many companies have tended to be skeptical about their business possibilities. When properly used to increase collaboration with clients and vendors, social technologies can help companies be more competitive and productive.

The Effects of Disruptive Technologies

What these disruptive technologies have in common is that they all increase access to information and promote powerful connections between people, organizations and technologies. Individually, each of these disruptive technologies can significantly impact the business world. Together, they will totally transform it.

Manufacturing companies must prepare for the possibility of a working environment in which data will be even more infused into every aspect of the business, computing devices will be everywhere, machines will be managing themselves and “talking” to each other, and connection and collaboration will be indispensable to maintaining a competitive edge.

The companies that will lead in this new world will not only adopt disruptive technologies but will take the next step of using them as tools to innovate their business.

How to Stay Ahead of the Herd

Because of the waves of change caused by disruptive technologies, companies must break completely free from the 20th century technology model of slow-paced innovation. They must now adopt new technologies more quickly and become innovators in their field to survive in the long term.

Non-adoption is no longer an option. Non-adopters and late adopters may have been able to get by with a wait-and-see approach before, but that will no longer allow them to thrive long-term. A company can go from being an innovator to a laggard if it fails to respond to technological changes in time. Kodak is an example of a former innovator that fell behind. Once the leader in the photography industry, with a level of brand recognition near Coca-Cola’s, Kodak was too slow in responding to the rise of digital photography. Kodak filed for bankruptcy in 2012 and its brand has been severely diminished.

Early adopters are companies that may not be innovators themselves, but that quickly realize the benefits of new technologies and are willing to utilize them. They understand it’s riskier in the long run not to adopt new technologies early enough. This gives them an advantage over their less forward-looking competitors. These companies may have what it takes to survive in the new reality, but they will need to innovate in order to achieve any sustained growth.

Those who innovate will be the leaders in their industries. Innovators can open up new markets by creating demand for new products or services. They change the game while others are only focusing on competing in the game. Because they set the pace of innovation instead of just trying to keep pace, they are much less likely to fall behind.

Innovation-Powered Manufacturing

The slow pace of change in manufacturing has created huge opportunities for companies to seize the mantle of thought leadership and shape the future of the industry by applying disruptive technologies. To accomplish this, companies will need to be brave, driven and innovative.

Innovation is the only way to lead and truly thrive in the long term. To be an innovation-powered manufacturer, your company has to be strongly focused on data: On gathering it in larger datasets and in real time; on extending it throughout your enterprise; on displaying it to more of your key employees; on increasing access to it through mobile devices, The Cloud, etc.; on analyzing it; and on basing your decisions on it.

The philosophy of an innovation-powered company is to open up the flow of information as much as appropriate, instead of locking information down. Manufacturers who operate this way will be aligned with the path of disruptive technologies, and therefore will be poised to ride the waves of change those technologies bring, rather than be overturned by them.

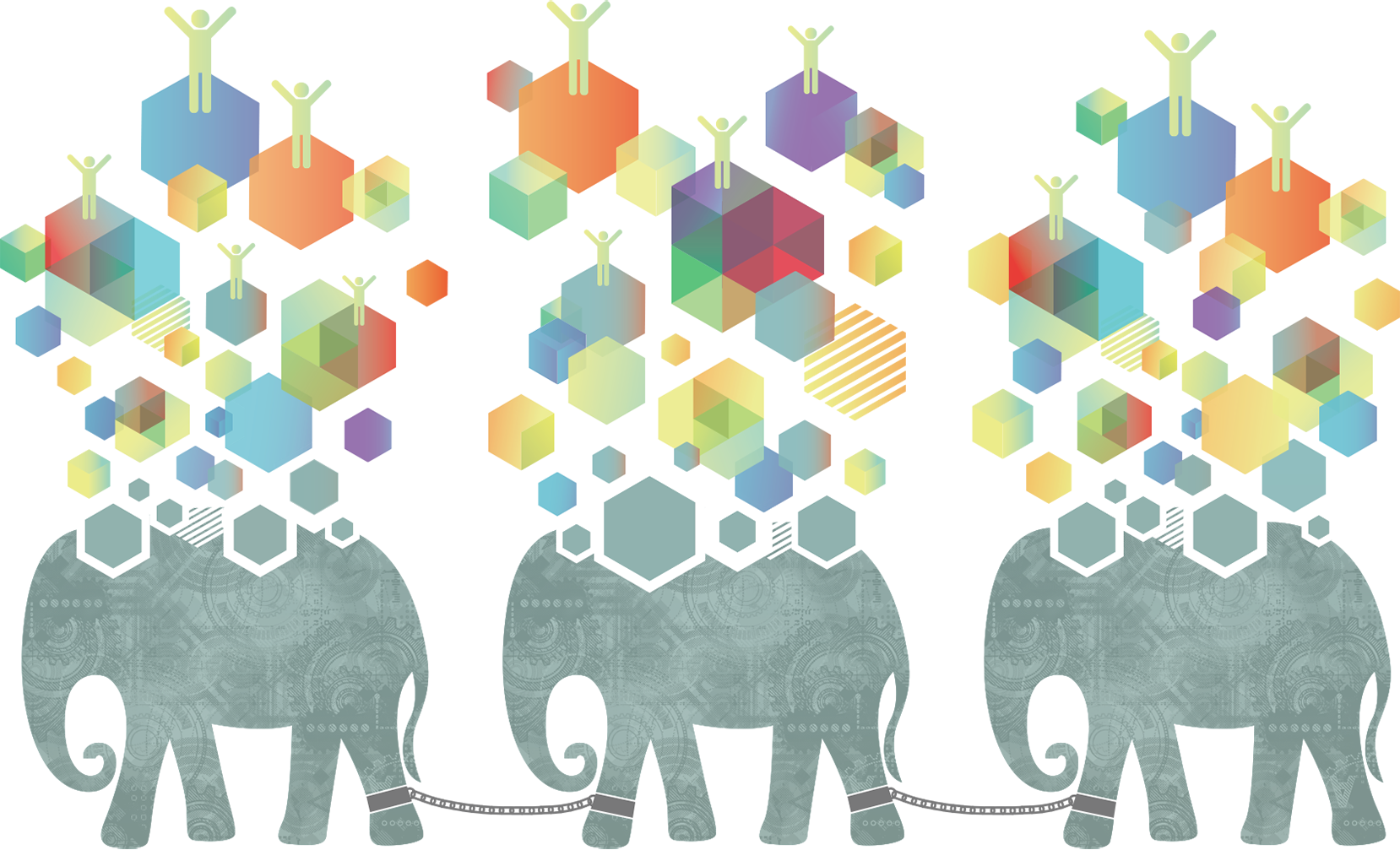

Cross-Pollination of Ideas: The Secret to Innovation

Innovation is not a goal that can be achieved once, and then checked off of a to-do list. It is a continual process that must become deeply ingrained in a company’s working process. One of the difficult aspects about being innovative is that, by definition, there is no “textbook” way to innovate. Taking an orderly and logical approach works well in most aspects of business but it will rarely lead you to anything innovative. That’s why many of the great innovations of our time came about by combining ideas from different fields. Like bees spreading pollen from one plant to another, people can cross-pollinate concepts and practices from one industry to another. The goal of cross-pollination between industries is to reach unexpected insights that wouldn’t be discovered in the course of business as usual.

The iPhone is a modern innovation that generated a legion of devoted customers and spawned new product lines (smartphones) and industries (app development, phone accessories). Sales of the iPhone propelled Apple even further to become one of the largest companies in the world. The iPhone was created in large part through a cross-pollination of products from different industries. It combined the power and flexibility of a personal computer, the fun of an MP3 player, and the function and portability of a cell phone. Many people probably thought that those three things wouldn’t blend together, but through cross-pollination Apple invented a profitable product and people across the world gained a new way to stay connected.

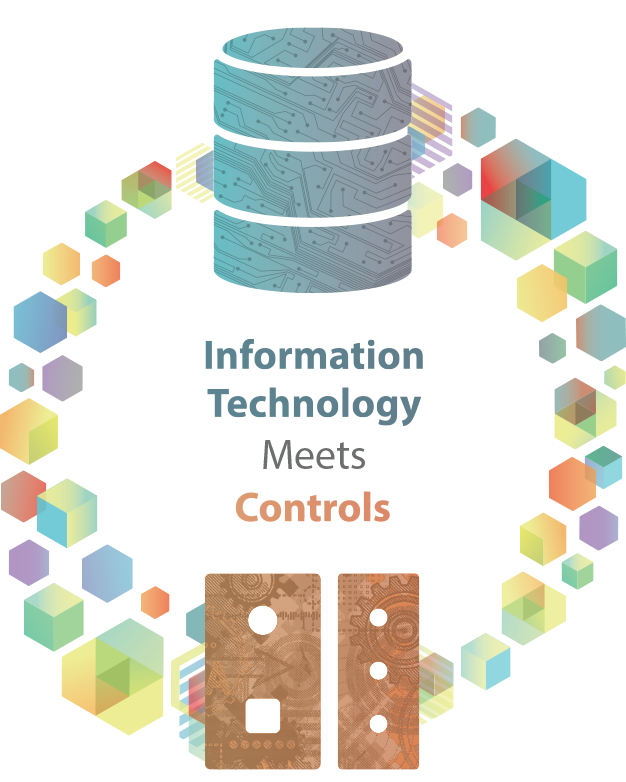

Another example of successful cross-pollination is how the industrial automation software company Inductive Automation combined IT and controls technologies to create its Ignition software platform. Ignition combines Structured Query Language (SQL) database compatibility and open coding languages from the IT world with supervisory control and data acquisition (SCADA) software from the world of system controls. Ignition also brings a licensing model from the IT world, which makes SCADA technology affordable and therefore more useful.

SCADA software users, accustomed to dealing with proprietary 1990s-era technology that is difficult to support, have discovered that Ignition is easy to use. Instead of coming with a restrictive licensing model that blocks growth, Ignition has unlimited licensing that unleashes growth. It can fit into a company’s existing process and allows them to streamline their process in the way they choose, rather than forcing them to work around the software.

By cross-pollinating controls and IT, Ignition breaks down communication barriers between IT and controls professionals, and changes the way that many companies think about SCADA software. The industry’s response has been huge: Since Inductive Automation launched Ignition in 2010, it has been installed in tens of thousands of facilities in more than 75 countries.

“When different ideas from different industries, people and processes come together, they have the power to form something newer and better than would otherwise be possible,” said Steve Hechtman, founder and CEO of Inductive Automation.

“The idea for Ignition came as a result of cross-pollination between the controls and information technology industries,” Hechtman continued. “Our company brought the best elements from those two industries together and it instantly took off. Ignition is an example of how having an open mind can lead you to new solutions."

Ways to Cross-Pollinate

Cross-pollination is an exciting process that can lead to innovation, but how can your company institute it? There may need to be a culture shift among your employees in order to incorporate cross-pollination into your regular work process. Consider these guidelines:

Connect to Other Industries

Seek out people who have jobs similar to yours who work in different industries. Then you’ll be able to share your challenges and get perspectives about them from knowledgeable outsiders. You’ll also be able to see what others are doing in their industries and think about how those practices can be applied to manufacturing. There are a number of ways to develop these contacts, such as attending a conference or seminar where multiple industries will be represented, or participating in a professional online network such as LinkedIn.

Share Ideas and Collaborate with Peers

This can be done formally (such as in meetings) or informally with co-workers who are within a department or from other departments. Employees can share their unique perspectives which are based on their job roles and work experiences. Forming collaborative teams can be an effective way to come up with good ideas and carry them out. Somewhere in your company, there may well be an employee who has a great idea but lacks the skills to execute it. You need to help that person connect with another employee who has the know-how to implement the idea, even if he or she might never have thought of it themselves.

Keep an Open Mind About New Ideas and Technologies

Ten years ago, how many marketing executives could have foreseen that so much of their time and attention would be directed toward a web platform with a silly name like Twitter? Looking further back, science fiction in the 50s and 60s predicted that space travel would be all the rage by now. But as you’ve read in this white paper, data is the new frontier that we’re most aggressively exploring today. The point is that it’s hard to predict which developments will shape tomorrow, so you shouldn’t dismiss new ideas just because they sound odd at first.

Making cross-pollination happen will require many employees to go a little outside of their comfort zone, at least initially. However, as you increase the flow of information and collaboration through your organization, you may find that cross-pollination starts to occur naturally.

Innovating Business Through the Free Flow of Data

Between People and Departments

Cross-pollination helps to fight the tendency of people and departments within an organization to become isolated from one another. Departments can become so focused on taking care of their specific functions that interdepartmental communication becomes minimal or nonexistent. The lack of communication sets up invisible walls that separate departments from each other. To the company as a whole, these walls between people and departments form a major barrier to innovation.

When someone or something manages to break through those walls, great improvements can take place. When Sierra Nevada Brewing Co., the sixth largest brewery in the United States, started using Inductive Automation software, they piloted it in a small area of the brewery called the CO₂ plant. Later, the brewery updated from Inductive Automation’s FactorySQL and FactoryPMI to its newer Ignition software and gradually rolled it out to other departments.

Prior to using Ignition, the staff had to communicate important analytical data such as yeast cell counts, temperatures and CO₂ values by walking around and hand-writing it on whiteboards placed throughout the brewery. If the whiteboards weren’t updated in time, it would create serious problems in the brewing process. Now with Ignition, this information can be communicated from one area of the brewery to another with the click of a mouse.

As workers in the brewery saw what Ignition could do, they requested more data from throughout the company. Ignition’s use has been extended beyond the production side of the business, and past the traditional bounds of SCADA. The accounting department uses it for various types of reporting. The sales department uses it to access database information, formulate and transmit sales projections, and interact with the ERP (enterprise resource planning) system. It’s used for logistics such as checking distribution trucks in and out. It’s even used to pull data from the database of their restaurant next to the brewery.

“As the company grows, the software grows,” said Jonathan Swisher, systems analyst for Sierra Nevada Brewing Co.

Between Different Systems

Even if communication between people and departments is improved, any lack of communication and cooperation between systems can still hold a manufacturer back. There is often a disconnection between the SCADA and ERP levels, and issues between proprietary and open-source software and between different versions of software.

Companies will go a long way toward reaching their potential for innovation by finding cross-platform technologies that can connect the plant floor with the enterprise level and work with any database or server.

Ignition software is designed specifically to empower companies to connect any system and any department. It lowers the barriers to innovation so companies can forge more powerful connections between technology and systems.

The key to Ignition’s flexibility is its modular architecture that enables manufacturers to select specific modules to meet their HMI, SCADA, MES (manufacturing execution system), and ERP needs. They can also select what they need from a suite of MES modules to bridge the gap between their plant floor and their enterprise to provide the benefits of ERP and MES integration. Ignition is Java-based, database-centric and database-agnostic, so it can help the whole company exchange vital information across all levels.

Innovation is a Choice

In the face of a rapidly changing world, manufacturers have a choice in how they will embrace emerging disruptive technologies. They can choose to act as a trained elephant – reluctant to move forward and held back by the faulty thinking of the past – or they can choose to be an innovation-driven manufacturer.

The way forward for manufacturers is to choose to open their minds to the new possibilities, embrace the changes and challenges that new technologies present, and use cross-pollination to innovate exciting new solutions to help shape the manufacturing industry of the future.

Unlike other software, Ignition is designed specifically to foster innovation and create more powerful connections between people, departments and systems. Even better, the open nature of the Ignition platform inspires the people who use it to think of exciting new possibilities, which is what ultimately fuels a company’s fire for innovation.

By committing to a path of continual innovation now, and facilitating innovation through a free flow of information and ideas, your company can be among those that achieve long-term success in a world transformed by disruptive technologies.

Recommendations

The following recommendations can help your company seize the current window of opportunity to lead in the industry and become an innovation-driven manufacturer:

- Reevaluate your current strategy for technology adoption. Remember: In the 21st century, it's riskier not to be an early adopter.

- Don’t be left behind. Prepare for the impact of disruptive technologies by adopting them early and using them to innovate new solutions for your business.

- Open up a free flow of data between people, departments and systems to increase innovation across your business.

- Drive your company’s innovative power by cross-pollinating ideas from different fields.

- Instill a company culture of cross-pollination by connecting with other industries, staying open-minded about new developments, and collaborating with peers.

- Seamlessly unite your HMI, SCADA and MES functions by using cross-platform, database-centric and database-agnostic software.

- Continually evaluate new technology as it becomes available – even if it seems odd in present day – and consider how you can leverage it to open new possibilities.

Want to stay up-to-date with us?

Sign up for our weekly News Feed.