You’ve Tried a Mortgage Calculator. Now Try a Plant Efficiency ROI Calculator.

Have you ever wondered how much you could save or profit by improving your plant efficiency? OEE calculations can be tricky, so at Vertech we’ve created an ROI Efficiency Calculator to make it that much easier.

Why OEE Matters

If you’ve worked in manufacturing for any length of time, you’ve heard of Overall Equipment Effectiveness (OEE) and probably even calculate this important metric at your manufacturing site.

As a quick refresh, OEE is a combined measurement of:

- Rate of Quality Products

- Total Availability (Uptime/Downtime)

- Performance Efficiency

The more you optimize OEE, the more you can keep costs low and production (and thus profits) high.

How to Track OEE

But how do you know how to improve, and where you are experiencing lower efficiency? And which improvements will make the most impact on your bottom line?

That’s where Ignition comes in. An OEE solution built in Ignition can automatically track and display production efficiency and equipment downtime in real-time. No more compiling data from various sources in Excel or doing rough calculations by hand.

A system like this could transform the way you track and control your production. But is improving OEE really worth it?

We created an ROI calculator to help you answer that exact question. It’s like a mortgage calculator but for plant efficiency. You can calculate how much you can save or profit by improving your OEE by even just a few percentage points.

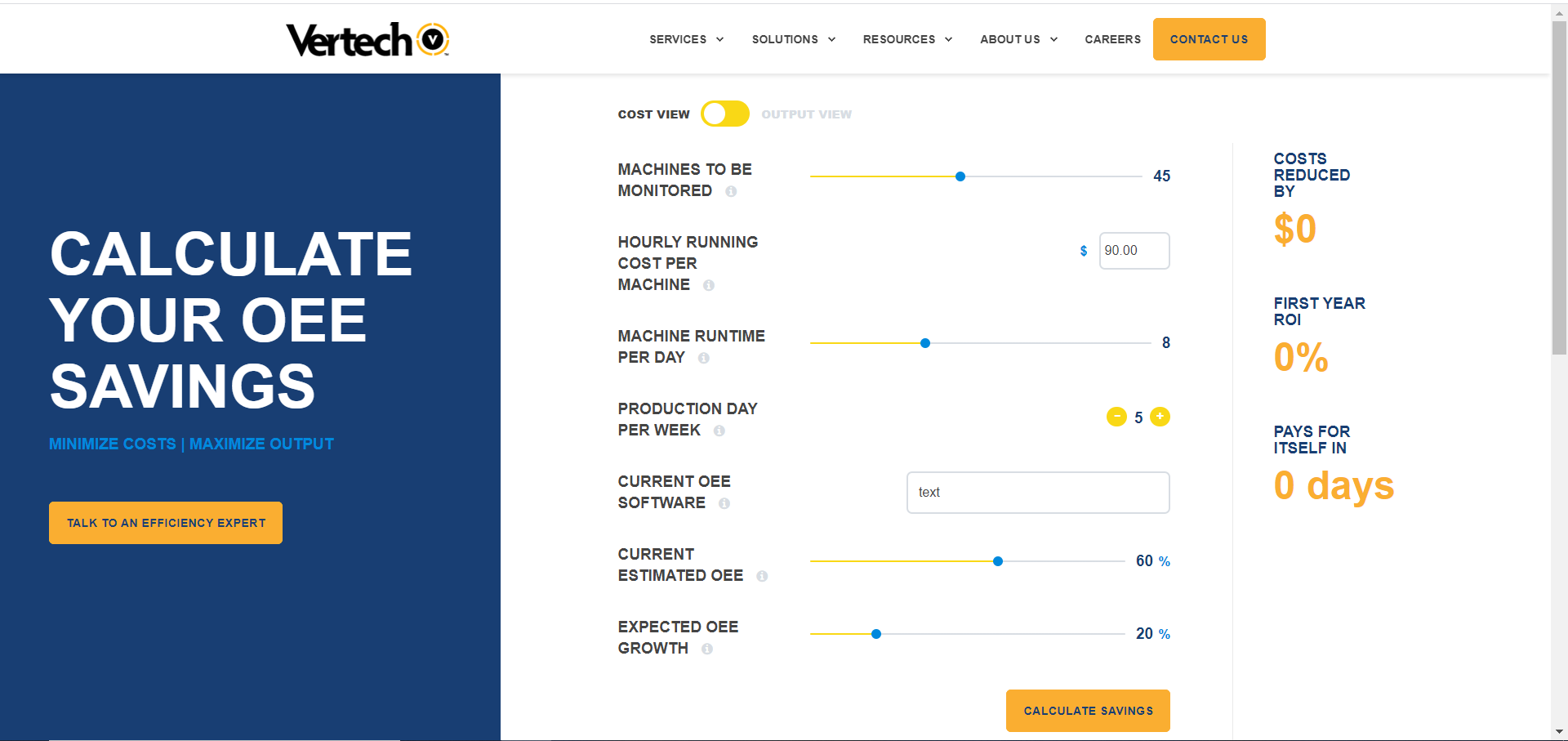

Using the OEE ROI Calculator

The OEE Calculator uses inputs specific to your plant as variables to calculate the bottom-line impact these improvements can have on profitability and cost savings. Knowing these numbers will help you make the case to invest in OEE tracking and plant monitoring.

With just a few clicks, the calculator will show you:

- Cost Reduction in Dollars

- Profit Increase in Dollars

- First-Year ROI Percentage

- Number of Days until the Plan Efficiency Pays for Itself

The calculator uses the following inputs to calculate your OEE ROI:

- Machines to be Monitored: The number of machines you want to monitor

- Hourly Running Cost Per Machine: The cost to run each machine per hour

- Machine Runtime Per Day: The number of working hours per day

- Production Days Per Week: The number of days per week the machines run

- Current Estimated OEE: Your baseline OEE right now, before any plan improvements

- Estimated OEE Growth Percentage: Your expected OEE growth

- Variable Cost Ratio: Your variable costs divided by your net sales

- Annual Revenue: Your estimated annual revenue for the year

Two Paths to ROI

The calculator allows you to view two different paths to ROI through OEE improvement: maximizing output and reducing costs.

Path 1: Cost View

In this first view, the OEE Calculator shows you your ROI through the lens of cost reduction. The calculator will estimate the cost of running your plant now and show your overall savings through scaled OEE improvements.

Path 2: Output View

In this second view, the OEE Calculator helps you estimate how much your profits will increase using your variable cost ratio. When you’re able to produce more quickly with less waste, your profits can jump by a substantial amount.

With the calculator in hand, you can play “what if” with your OEE ROI and see exactly how each variable makes a difference.

Ignition OEE Solutions in Action

In addition to ROI, there are other benefits to improving your plant tracking and monitoring, which go beyond baseline OEE cost/profit improvements. They include improved reporting, real-time data, ease of planning, and flexibility for future growth.

For example, when Amy’s Kitchen upgraded their OEE system to Ignition across 3 of their production sites, they were able to automatically track and display production efficiency and equipment downtime, reducing manual monitoring and reporting. The insights gained allowed the team to optimize their production for each plant and empowered them to easily plan for future expansions.

Four Roses Bourbon saw similar benefits. The Ignition system implemented by Vertech greatly improved Four Roses' ability to easily see their facility processes and keep track of all of the data needed to effectively run the plant. By giving Four Roses a view into real-time production, efficiency, line reliability, as well as top problem areas, managers were able to gauge the effectiveness of process changes and continuous improvement.

If you’d like to estimate your OEE ROI, please check out the calculator here. And if you’re ready to explore an Ignition OEE solution and transform the way you monitor your plant, feel free to reach out to Inductive Automation or the team at Vertech. We’ll be happy to help you explore what’s possible in production tracking and control.