5 Reasons Ignition is More Than Just SCADA Software

Explore a Unified Platform with Unlimited Potential

14 minute read Download PDF

Table of contents

- Ignition can do much more than SCADA.

- You can build your SCADA software around your process.

- You can get MES and ERP to work, all in one place.

- You don't get charged like SCADA software.

- You can get EVERYTHING to work together.

- You can understand your data and operations like never before.

- Get ready to change your game.

In a competitive global economy, it’s crucial to make the most of every asset your company has. That means getting the most value from your budget and the most utility from your tools; why buy a single blade when you can get a Swiss Army knife? This idea extends to your company’s software.

Supervisory control and data acquisition (SCADA) software is used by companies and other organizations around the world to monitor, gather and process data, and to control automated processes. SCADA software plays a critical role in a wide variety of industries that impact our everyday lives, such as manufacturing, utilities, water, oil and gas, healthcare, mass transit, and more.

SCADA Defined

SCADA is an industrial control system at the core of many modern industries. SCADA systems deploy multiple technologies to monitor, gather, and process data as well as to control equipment. Virtually anywhere you look in today’s world, you will find some type of SCADA system running, whether it’s at your local supermarket, refinery, waste water treatment plant or even your own home.

SCADA systems range from simple to large and complex. Most utilize HMI (human-machine interface) software that allows users to interact with and control the machines and devices connected to the HMI, such as valves, pumps, motors and much more.

SCADA software receives its information from RTUs (remote terminal units) or PLCs (programmable logic controllers) that receive their information from sensors or manually inputted values. From here, the data can be used to monitor, collect and analyze data, which can reduce waste and improve efficiency.

Modern SCADA systems allow access to realtime, plant-floor data from anywhere in the world. This real-time access to information makes it possible for end users to make data-driven decisions about how to improve their processes. The introduction of modern IT standards and practices such as SQL and web-based applications into SCADA software has greatly improved the efficiencies, security, productivity and reliability of SCADA systems.

Ignition can do much more than SCADA.

In just a decade, Inductive Automation has established itself as the fastest-growing SCADA software company in the world through our software platform, Ignition by Inductive Automation®. But here’s a surprising fact that is also a key to Ignition’s success: Ignition isn’t exactly “SCADA software.” That’s because Ignition’s capabilities expand and surpass the narrow definition of what standard SCADA software is considered to be.

This is the one of the most difficult perceptions to overcome when explaining the capabilities of Ignition. Like a Swiss Army knife, it is far more versatile than it appears at first glance. Yes, Ignition is a great solution for HMI, SCADA and MES, but the truth is that it can do so much more!

So what sets Ignition apart from the rest of the SCADA software out there? Keep reading for five reasons why you can do so much more with Ignition.

You can build your SCADA software around your process.

Other SCADA software platforms out there are set up in a certain way – the way the software company made them. As any systems integrator can tell you, one size does not fit all when it comes to SCADA systems. Although you can spend a lot of money and time on SCADA software, you often find that it can’t do what you need it to do.

If you need a new feature, you have to request it from the company and then wait for them to maybe get around to it. The length of the wait depends on how frequently the company gets that particular request and, most likely, your request is one out of a huge number of requests for new features. While you understand this, it’s still frustrating, especially when you’re requesting something that you or your client urgently needs. And how can you plan for your future needs when you’re boxed in to the software company’s way of doing things?

Ignition is different:

It’s built with your unique processes in mind. After all, your unique processes are the source of your competitive advantage. If you’re forced to change how you do things just because the software you need is set up one particular way, it hurts your business.

Ignition is like a blank slate – you make it do what you need, how you need. Ignition is built with databases at its core, based on modern IT standards and is cross-platform compatible. It works with any database, any device, and any operating system, regardless of version. That includes every version of Microsoft® Windows, so you won’t need to worry about the next time Microsoft® ends support for one of its products.

“The flexibility that you gain with Ignition over other SCADA brands is hard to really put a price on, because what you think you need today is not what you’re going to need tomorrow,” says Charlie Hendrixson, director of automation services for MillerEads Automation in Indianapolis, Ind. “Trying to plan ahead for the future when you’re working under a rigid licensing structure is very difficult.”

Hendrixson also says, “Even though Ignition is sold under the SCADA name, it’s not SCADA. At its core, it is a development platform.” Miller-Eads has used Ignition to develop a unique system for a customer of theirs that manufactures equipment for professional athletes. Their customer is using Ignition to run almost every aspect of their manufacturing facility including HMI / SCADA, MES, production, recipe, quality control and machine control, and is constantly expanding Ignition into different areas of their operations.

The athletic-equipment company faced some unique challenges because it utilizes a process line that switches between hand-building and machine-building, and employs a multicultural workforce. Because some steps in their customer’s process only involve human workers, Miller-Eads built them a system that uses the worker as a sort of human PLC to collect usable data that is then correlated throughout the process. With Ignition, the company can run reports that trace every step that each piece of material makes through the facility and show photos of every worker who handled it. Also, since multiple languages are spoken on the plant floor, Miller Eads designed user-interface touchscreens with visual symbols so that language differences aren’t an issue. Hendrixson says this kind of solution might have been impossible and would certainly have been costlier in any other type of development environment.

Ignition is a powerful platform that you can build on for your own needs, and in the way you choose. This flexibility helps you preserve your competitive advantage instead of having to compromise it. As we like to say to end users, “Ignition is built around you.

You can get MES and ERP to work, all in one place.

In addition to SCADA software, which runs on the plant floor, many manufacturing companies also utilize manufacturing execution systems (MES) and ERP software.

What does ERP stand for? Enterprise resource planning, which is a system used to manage all of the office level processes like collecting, storing, and using data for their supply chain, product planning, human resources, reporting, manufacturing, and distribution.

MES software, which is sometimes referred to as manufacturing operations management (MOM), deals with production scheduling, overall equipment effectiveness (OEE) / downtime, preventive maintenance, auditing, statistical process control (SPC) and more. MES can be thought of as a middle layer between SCADA and ERP, the latter of which handles many aspects of business management such as supply chains, procurement, human resources, financials, sales and more.

SCADA and ERP systems are more commonly used than MES systems, even though MES gives SCADA end users increased connection with their data to improve efficiency, productivity and quality. MES solutions commonly require other systems like ERP, so it’s highly beneficial to have one solution that can bring SCADA, MES and ERP together.

However, most control systems are about 10 years behind the technology curve. They don’t work with the modern IT technologies (such as Java, the web and SQL databases) that are pervasive at the enterprise level. The gap between SCADA, MES and ERP keeps many companies from connecting up their whole enterprise. Unfortunately, this gap between systems leads to unnecessary waste and missed opportunities.

Ignition is different:

Ignition has led the way in effectively merging modern IT technology with control systems. With Ignition, you can connect and work seamlessly with any MES or ERP system, which allows data to flow smoothly throughout your whole organization.

Ignition even has its own suite of specially built MES modules. You can add MES modules to your Ignition platform or easily integrate Ignition with an existing MES system, and then connect to the ERP system of your choice.

The more that you use Ignition, the more you’ll see that it is unlimited. It can be used by sales and marketing departments as well as by operators on the plant floor. It breaks down the walls between SCADA and other systems, resulting in efficiencies that would not be possible otherwise.

You don't get charged like SCADA software.

Typical SCADA software companies base their pricing around the number of people you want to have using the system and the amount of data you want to track via tags – it’s based on the size of your plant and the number of physical pieces you have.

“With other software, it almost seems like if you want to have a modern practice with PLCs and controls and you want to have a SCADA system, then they’re going to hold you hostage. It really doesn’t feel that way with Ignition.” – Charlie Hendrixson Director of Automation, Miller-Eads Automation

This type of pricing scheme is only good for the software vendor, not for the integrator or end user. The costs add up every time you want to add to your SCADA system, and it can be frustrating when your expansion plans are halted just because your SCADA software licensing costs shoot through the roof.

Proprietary licensing drains your budget and depletes your ability to innovate. How are you supposed to innovate when licensing costs make it too expensive to upgrade or expand your industrial equipment?

Ignition is different:

Its licensing is extremely simple: You buy one server license and get unlimited clients and tags. You get as many connections as you want, which is very rare with this type of software. Adding on to your system doesn’t cost anything from a software standpoint. So now you can use your software without feeling confined by licensing limitations, such as having to justify buying a seat license every time you want to add a user.

Instead of restricting your growth, Ignition’s unlimited licensing sets your potential for growth free, which gives you a far greater return for your software investment.

“It’s a modern licensing practice, and it doesn’t feel proprietary,” Hendrixson says. “With other software, it almost seems like if you want to have a modern practice with PLCs and controls and you want to have a SCADA system, then they’re going to hold you hostage. It really doesn’t feel that way with Ignition.”

In addition to bringing IT technologies to controls, Ignition brings a by-the-server licensing model from the IT world. By making SCADA technology affordable, it makes it more useful. The unlimited licensing opens up unlimited possibilities.

You can get EVERYTHING to work together.

When was the last time you could get all of your software pieces to work in one place? Usually, you have to log into multiple software pieces to configure them. Each time you add new software, you most likely have to maneuver around different software pieces to make the new piece fit with your existing software – or just relegate it to its own corner of your system, where it becomes a data island. That’s frustrating!

Older SCADA software doesn’t use modern communication protocols, which makes it difficult to get hardware from different vendors to communicate with each other. The usual “solution” to this problem is to add expensive proprietary drivers that cause more frustration on the plant floor.

Ignition is different:

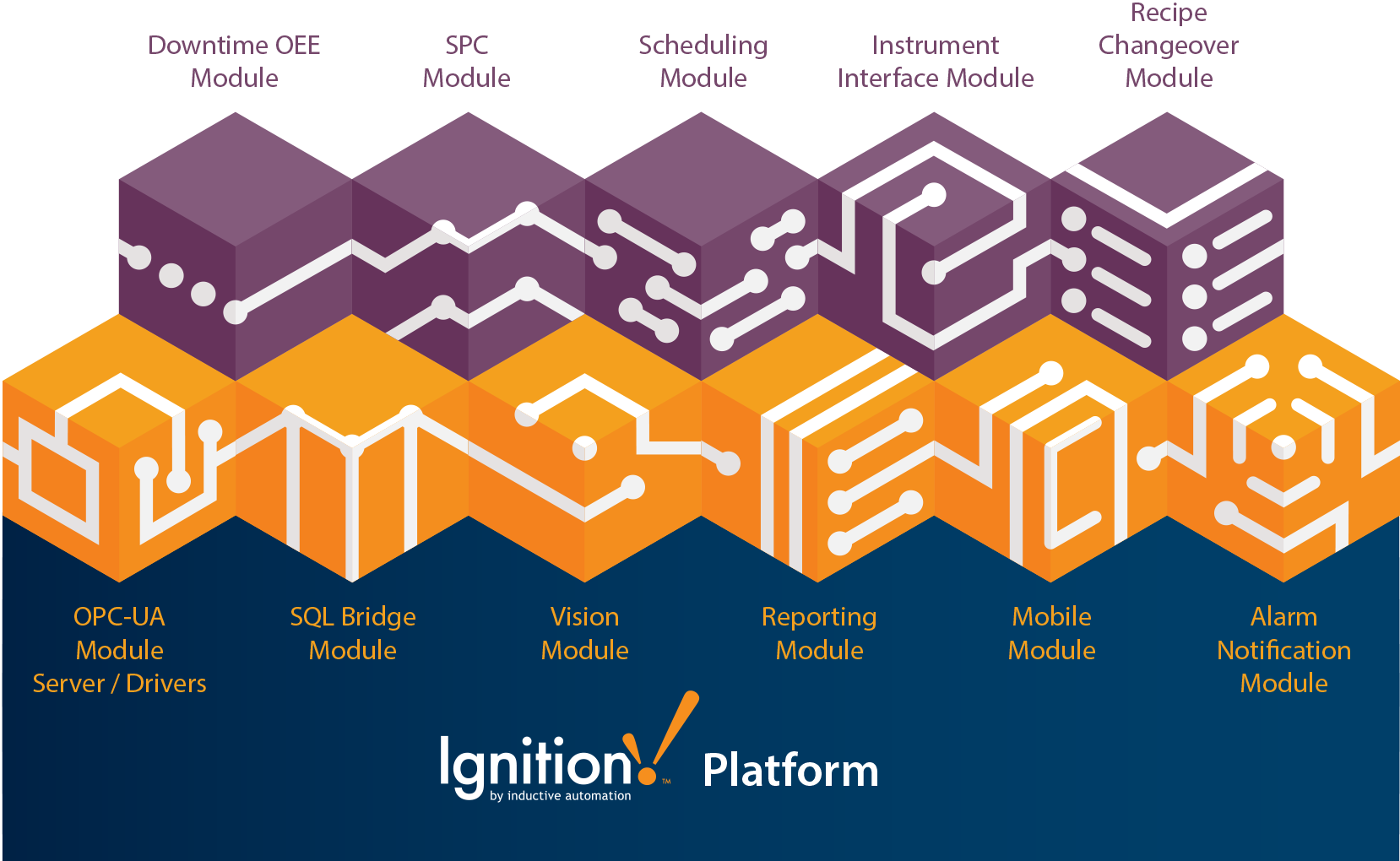

It has two main parts: the platform and the modules. Ignition’s modular architecture is the key to why it will always work regardless of what other software you add in the future.

The platform holds all the pieces that make the software work with everything else and the modules add specialized functions to the platform.

Some modules are included with Ignition and some have to be plugged into it. There are Ignition modules for alarming, templates, project development, screen design, data management, MES, scripting functions and much more.

One of the modules included with Ignition is the OPC-UA Module which lets you connect to PLCs or remote terminal units (RTUs) on the plant floor. OPCUA is the industrial automation industry’s current standard cross-platform framework for accessing real-time and historical data. The Ignition OPC-UA Module lets you connect to most major PLCs and to any third-party OPC server. It’s the world’s first totally cross-platform OPC-UA server with an open, pluggable driver system that makes the old problem of getting everything on the plant floor to work together suddenly easy. Also, Ignition was the first SCADA system to offer a built-in OPC-UA server instead of making you buy a third-party OPC-UA server.

You can understand your data and operations like never before.

High-speed automated processes don’t want you to analyze what’s happening in the now. Most SCADA software uses historians, which use proprietary technology to compress and store data. As a result, time-series data is often kept totally separate and detached from the rest of the enterprise data; not because it has to be, but because historians make it difficult for other systems to work with it.

If you want to get your data out of your historian software and into a database, you have to jump through hoops. When you finally get your data in a usable format like a .xls or .csv file, the hours or days that have passed make it irrelevant because your plant has already moved on to the next production process.

Ignition is different:

It uses SQL databases to log and store data. And since your data is stored into a database in real time, it’s available in real time because you didn’t have to pull it out of proprietary historian software!

Ignition lets you view real-time trends, cross-reference any number of data sets – and you can do it on an ad-hoc basis. This means that you can get answers to important questions about real-time data in milliseconds, not hours or days.

In addition to real-time data, historical data is a potential gold mine of information. The only way you can put time-series data into context is to make it relatable to the data from the rest of your enterprise. At any time, you can use Ignition to give the data context and gain a better understanding of what’s really going on, and what you can do about it.

Get ready to change your game.

In a competitive industry where every second counts, Ignition is a game-changer. You can build a normal SCADA system with Ignition – but the true magic of Ignition happens when you discover that you can go beyond SCADA. You can build whatever tracking, monitoring, control or data analysis screens that you need to run your business better, without worrying about software costs. Get everything connected and working together with ease and start doing things with your data like never before.

The Ignition difference runs even deeper than its flexibility, the benefits of ERP and MES integration, its licensing model, its interoperability or its real-time data. The fundamental reason why Ignition is more than SCADA is in the way it’s built: as a unified platform with perfectly integrated modules for separate functions.

Steve Hechtman, the founder, president and CEO of Inductive Automation, worked for 25 years as a systems integrator before starting the company. He reached a point of great frustration with the limitations and hassles of SCADA software. “When we were first developing Ignition, there was no simple way to connect a database with a PLC or to web-launch clients. It was like there was this giant wall separating us from what we wanted to do with SCADA, and then as we looked more closely at the wall we started to find some loose bricks,” Hechtman says. “Then, after we took out those bricks, we asked ourselves, ‘Wow, what if there are more loose bricks?’ And then, pretty soon we’d made a hole in the wall and we could see what is on the other side.”

Ignition tears down the walls around SCADA software. It not only meets your needs but becomes a tool for innovation. It allows you to dream up new possibilities and develop them – and what SCADA software can do that?

Find out why Ignition is the best SCADA software available today — and much more.

Want to stay up-to-date with us?

Sign up for our weekly News Feed.