Ignition MES Software

Standardize Your MES System Enterprise-Wide

Call us to get started with MES

The Ideal Platform for Amazing MES Solutions

Ignition is the ideal platform for MES (manufacturing execution system) because you can connect, monitor, and control your manufacturing data to create systems that ensure effective execution of operations and improved production output. Inductive Automation has teamed up with our strategic partner, Sepasoft, to offer a strong lineup of MES solutions for the Ignition platform. The Sepasoft MES modules for Ignition provide control, traceability, and documentation of the transformation of raw materials into finished goods in real-time.

The Benefits of Using the Sepasoft MES Modules for Ignition:

Track Material from Start to Finish:

Improve accountability with enterprise-wide traceability

Reduce Development Time:

Build first-class MES applications faster with powerful development tools

Better Analyze Your Performance:

Improve equipment effectiveness and reduce downtime

Enterprise-Wide Scalability:

Make better decisions with real-time enterprise-wide production data

Align with ISA 95:

Conform your process to ISA 95 standards

Supported by Sepasoft:

Get support help from the MES experts at Sepasoft

“Samtec picked Ignition and Sepasoft because of it’s flexibility and its ability to quickly connect to machines and to get us the real-time data very quickly, to be able to throw up dashboards and all these things very rapidly.”

– Jordan Rajchel

Samtec

See how hi-tech manufacturer Samtec realizes continuous improvement with the Sepasoft OEE Downtime Module.

Watch the case studyMajor Features

Standardizing Your MES Process with Sepasoft’s Modules for Ignition

With solutions for OEE (Overall Equipment Effectiveness) and downtime, track and trace, SPC (Statistical Process Control), recipes, changeover, and more, Inductive Automation’s strategic partner, Sepasoft, offers Ignition software modules for companies who are looking for an MES solution to standardize their operations enterprise-wide. The MES experts at Sepasoft build all their MES modules in alignment with the rigorous ISA 95 standard for enterprise control system integration.

Connect to all Operational Data

The Ignition platform comes with a comprehensive set of tools for data acquisition, including built-in SQL-database integration and OPC UA for easy connectivity to practically any PLC through third-party OPC servers. Ignition can connect to virtually any industrial historian. Through the addition of integrated third-party software modules, Ignition can also connect to any IIoT-capable device using MQTT and serial devices, such as scanners, scales, and sensors.

Screen courtesy of Vertech

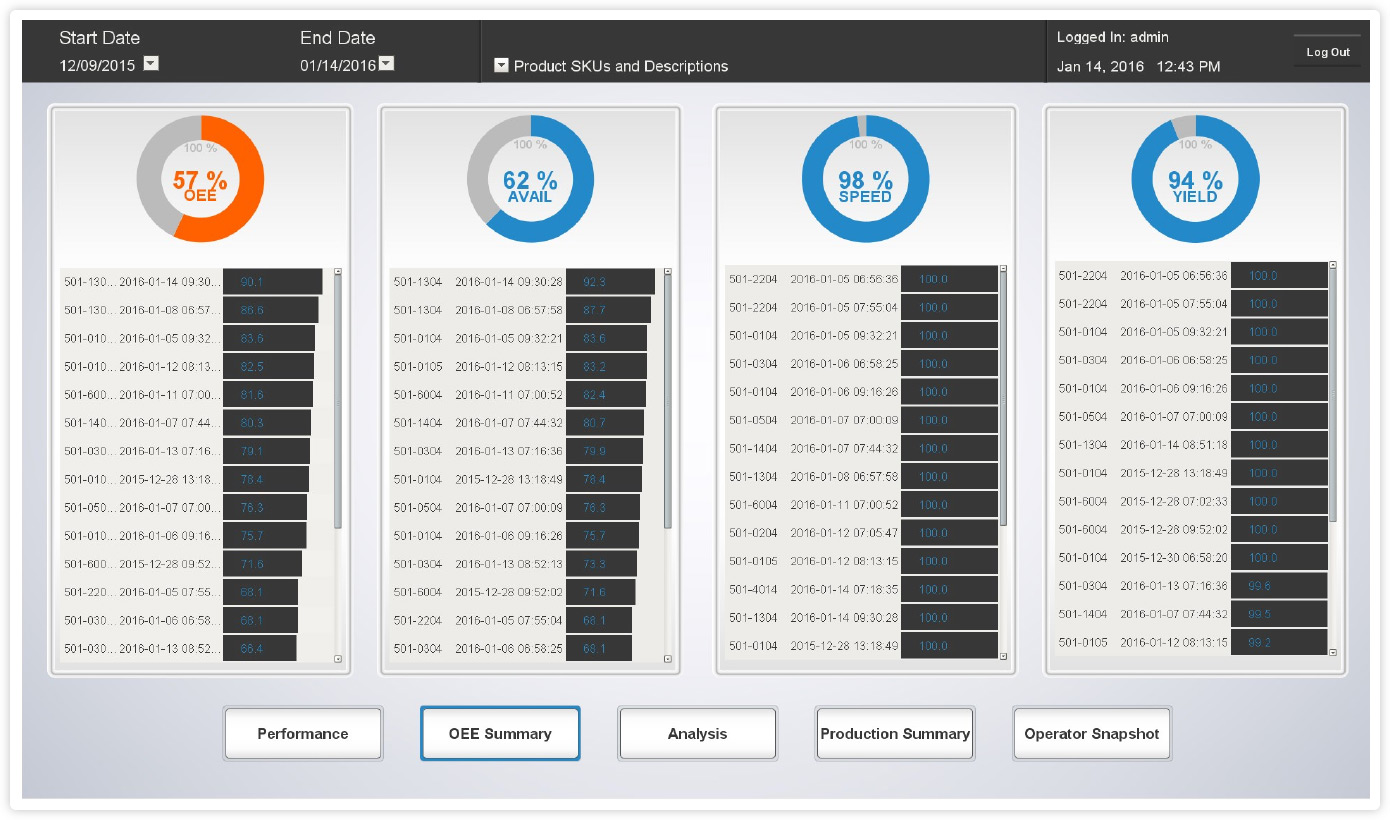

Improve Equipment Efficiency

Sepasoft’s OEE Downtime Module for Ignition combines both OEE calculations and downtime tracking to give operations managers a robust software package that measures efficiency and insight into how to boost OEE.

Track Raw Material

The Sepasoft Track & Trace Module for Ignition is a paperless, fully integrated solution that provides production control and product tracking from the raw materials to the finished state. With the Track & Trace Module, you can access genealogy data, and set up a centralized operator interface for all your MES information.

Improve Quality Control

Reduce or eliminate late or missing sample collection, inaccurate sample data with Sepasoft’s SPC Module for Ignition. With the SPC Module you can find and resolve issues leading to quality problems and deliver and analyze your SPC data in real-time.

Manage Recipes

With Sepasoft’s Settings & Changeover Module for Ignition you can expertly build, manage and monitor recipes and quickly and accurately change machine, process or system recipes.

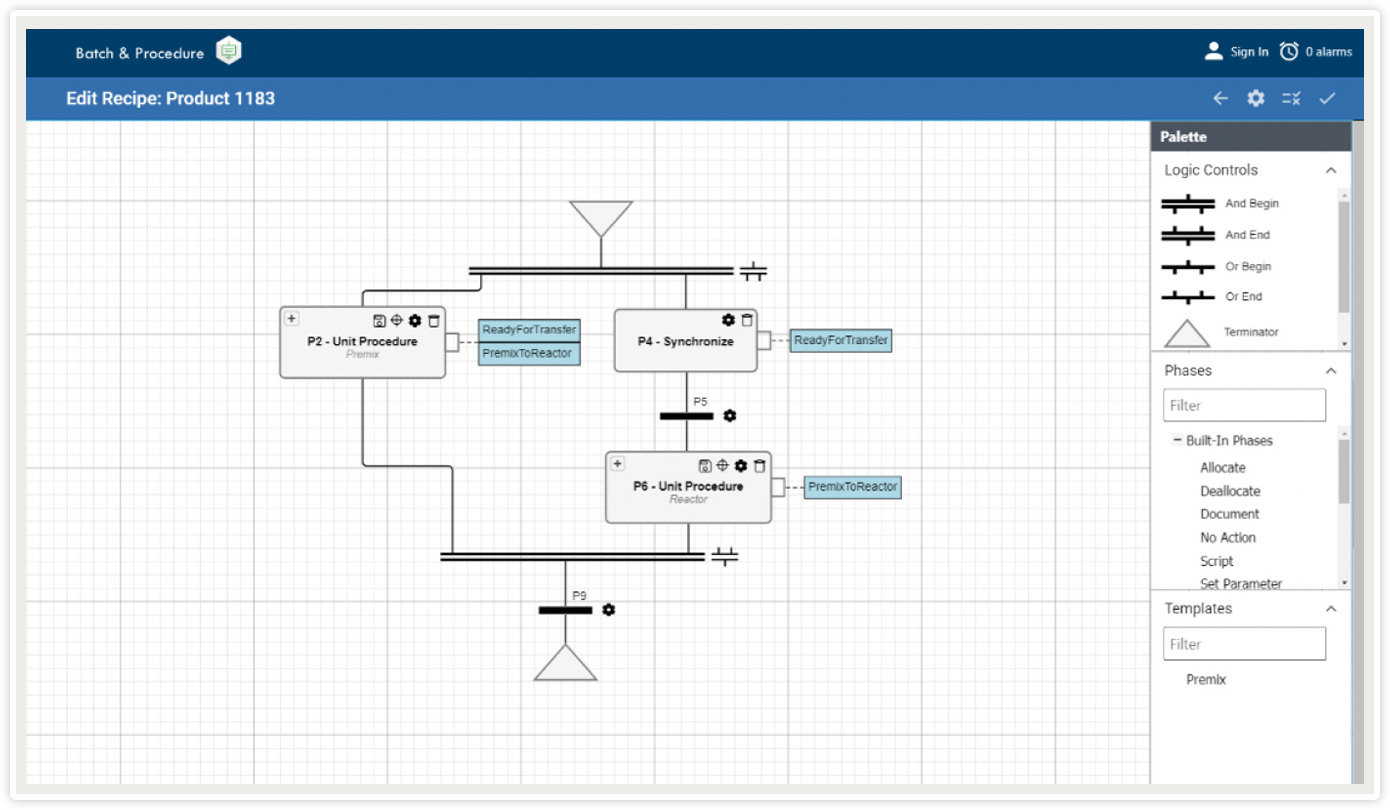

Consolidate Recipe Processes

By leveraging Sepasoft’s Batch Procedure Module for Ignition, you can add batch processing, continuous processing, and general procedure control based on ISA-88 standards to your operations. Whether you are producing multiple products or running several machines in different modes, the Batch Procedure Module simplifies the managing and editing of production recipes.

Connect to ERP Systems

Ignition comes standard with the ability to seamlessly connect to any SQL database and REST web services. In combination with Sepasoft software modules, Ignition also has the ability to manage REST and SOAP web service configurations, including both hosting endpoints and clients, as well as connectivity to virtually any enterprise system including ERP systems such as SAP, JD Edwards, and many more.

Take MES Enterprise-Wide

Using MES Enterprise for Ignition from Sepasoft, you can connect multiple MES Ignition Gateways across your entire enterprise to form a large, centrally managed MES solution. With MES Enterprise you can analyze MES data from multiple production facilities at a single enterprise server.

More Features

Do Even More with Ignition MES

Seamless Integration with Ignition SCADA

All Ignition solutions work seamlessly together for easy system integration.

Dynamic Reporting

Create a full range of dynamic, data-rich reports and send them anywhere.

SCADA Alarming

Easily stay aware of what’s happening at your facility, wherever you are.

Industrial Historian

Turn a SQL database into a high-performance time-series tag historian.

Transaction Management

Easily log data, call stored procedures, and synchronize data bi-directionally.

Built on Open Standard Technologies

Based on easy-to-support IT standards like SQL, Python, MQTT, and OPC UA.

Instant Installs and Updates

Install on a server in just 3 minutes; push updates to clients everywhere, instantly.

Totally Cross-Platform

Works on Windows, Linux, macOS, and more.

Concurrent Web-Launched Designers

Comes out the boxes with the industry’s most powerful IDE—for free.