What Is MES?

An Explainer From Inductive Automation and Sepasoft

4 minute readTable of contents

MES Explained

MES stands for manufacturing execution system, meaning a control system for monitoring and managing work-in-process on the factory floor. But that’s an oversimplification of what a successful MES software implementation can do for manufacturers.

MES for Manufacturing

MES provides detailed resource scheduling and status, production dispatch and sequencing, traceability, genealogy, inventory, quality assurance, maintenance management, document control, performance analyses, and more.

MES is crucial for manufacturers because it exists in the space between business-oriented applications like ERP and SCADA/HMI systems designed to directly control plant-floor operations. While an ERP can help allocate resources, it lacks the level of detail that MES provides. MES allows for real-time, minute-to-minute — or quicker — resource scheduling, as well as handling execution and dispatch.

MES connects production to executive decision-making by controlling, tracking, and documenting the transformation of raw materials into finished goods in real time. This information gives a current, accurate view of plant-floor operations, especially when combined with dashboards that display current statuses and rates, which can be compared to both historical data as well as scheduled production goals.

Similarly, MES assists with recipe management, allowing organizations to formulate consistent methods for creating products from batch to batch, reducing waste while streamlining processes. Additionally, recipes can be easily updated and altered, quickly adding new products or adjusting the spec of current offerings.

MES manages work-in-progress, or WIP, inventory throughout the various stages of production. By integrating with ERP and SCADA systems, MES automatically validates inventory levels at each stage, eliminating the need for manual verification.

Track and Trace

Related to WIP inventory is the concept of track and trace, which documents batches and individual products on their journey from raw materials to semi-finished goods and finally to finished products. By tracking, organizations gain a complete picture of each unit and can instantly trace its path through production in the case of a quality fluctuation.

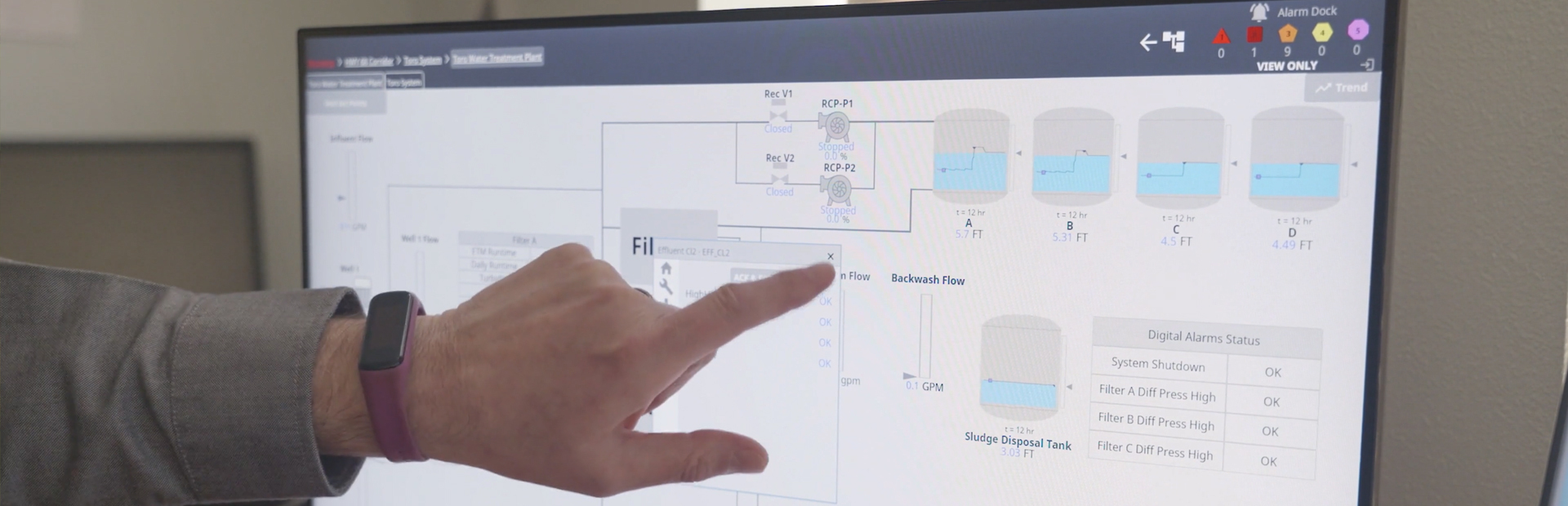

All production facilities will have variations, deviations, and exceptions in terms of quality and accepted parameters. Connecting MES to a more granular SCADA system allows operators to see alarms that indicate in real time when units are out of spec.

MES and OEE

While not technically part of the system itself, Overall Equipment Effectiveness, or OEE, is closely linked to MES. OEE considers three ratios: actual runtime to planned production time, the number of units started to the number of units processed at the standard rate, and good units produced to units started.

Using these ratios, organizations can analyze their operations, gain valuable insight, then improve production and equipment throughput.

A large factor in OEE is downtime tracking. Every minute of downtime on the plant floor means losing money, and puts production behind schedule. Reducing, or even eliminating, downtime is vital to meeting production goals and becoming a more efficient organization.

Ignition and MES

One of the best ways to implement an MES solution is to use the Ignition software platform with Sepasoft’s suite of MES modules.

Ignition acts as the base, with built-in tools to develop best-in-class SCADA, HMI, and even ERP solutions. With a server-centric architecture, paired with its unlimited licensing model, Ignition brings cutting-edge automation software to both the plant floor and the board room. A versatile solution like the Ignition Perspective Module can easily connect data sources from across the organization, displaying that information on flexible, dynamic dashboards, and generating custom reports, all in a mobile-responsive application.

Sepasoft’s modules slot right into Ignition, expediting MES development while delivering a powerful feature set including batch processing, downtime monitoring, procedure management, and more.

MES can be complicated, and creating a custom solution from scratch can be difficult to build and even harder to maintain. Alternatively, Sepasoft’s low-code solutions reduce development time, minimizing technical debt and total cost of ownership.

In one way or another, all organizations have a manufacturing execution system, whether it’s automated, manual, or tracked completely in the mind of one person. But in a plant floor environment where consistency is vital and downtime can be catastrophic, implementing a true MES will not only improve efficiency — it will help manufacturers become stronger businesses.

Related Content

Want to stay up-to-date with us?

Sign up for our weekly News Feed.