Sterilization Scheduling Application Eliminates Recipe Control Gap For Pharmaceutical Manufacturer

Ignition Transforms Complex Processes & Allows For Long-Term Planning

6 minute read Download PDF

In an industry like pharmaceuticals, maintaining quality and compliance is a strict requirement, not an optional goal. Outdated or ineffective technologies and methods can not only hamper efficiency, but also stunt growth and potentially affect product quality.

That was the situation Sandalwood Systems Integration Group found itself in with one customer who was having difficulty bridging the gap between their scheduling application and their ERP system. Sandalwood leveraged Ignition — an industrial automation platform for SCADA, HMI, IIoT, and more — to deliver a solution that completely revolutionized the customer’s production processes.

Minding the Gap

The customer was struggling with a recipe control gap. While their ERP system provided meticulous high-level recipe control and monitoring, the plant floor lacked real-time data as well as access to scheduling and optimization tools, relying instead on an in-house Excel-based application to schedule multiple sterilization lines.

Sterilization scheduling can be a complex process: components must be sterilized in time to feed fill lines, which are predicated on the downstream demand of the final product. On top of that, the existing inventory of sterilized components needs to be considered when determining production quotas. Relying on Excel macros for batch preparation did not offer the flexibility or scalability required to effectively manage the sterilization lines, resulting in a system that could only schedule a few days at a time, hindering long-term planning efforts.

“We were initially given a copy of the Excel-based application and asked to duplicate it in Ignition, which acted as our initial requirements,” said Bob Sloma, Digital Transformation Lead & SME, Systems Integration Services at Sandalwood. “As you can imagine with an Excel-based application, figuring out what they were doing by analyzing the VBA code was a challenging task.”

Even consulting with the application’s developer, it was a challenge to dig through layers of code and determine which reports were actually being used, as it became evident that certain reports were more vital than others.

The Excel application determined the best overall schedule by calculating all possible routings and their overall durations. This brute-force approach could not produce a full schedule without overloading the machine running the application. Clearly, it had reached the limit of its efficacy. “I have significant experience with MRP and production scheduling with my 30-plus years of experience and knew there was a better way to do this,” said Sloma.

Batch Production Scheduler

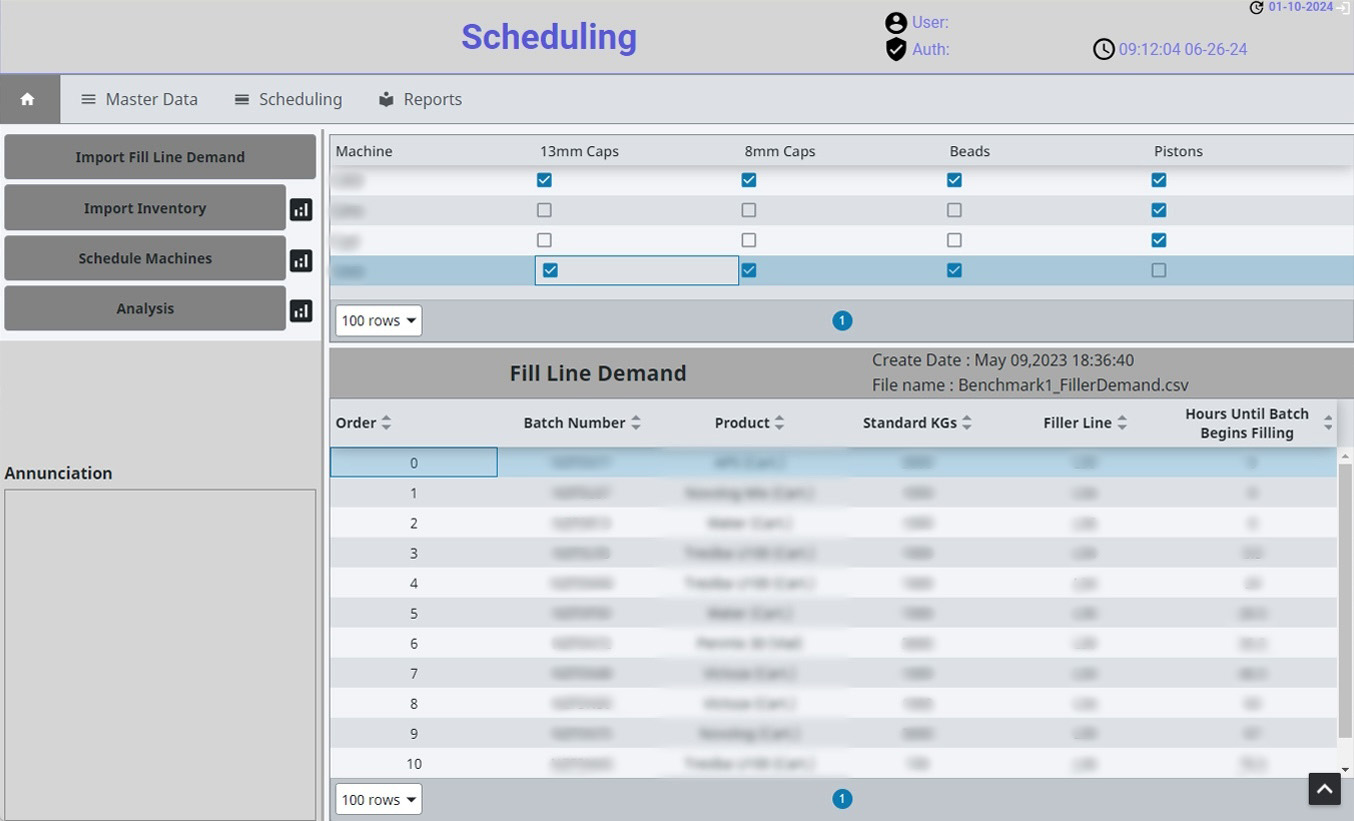

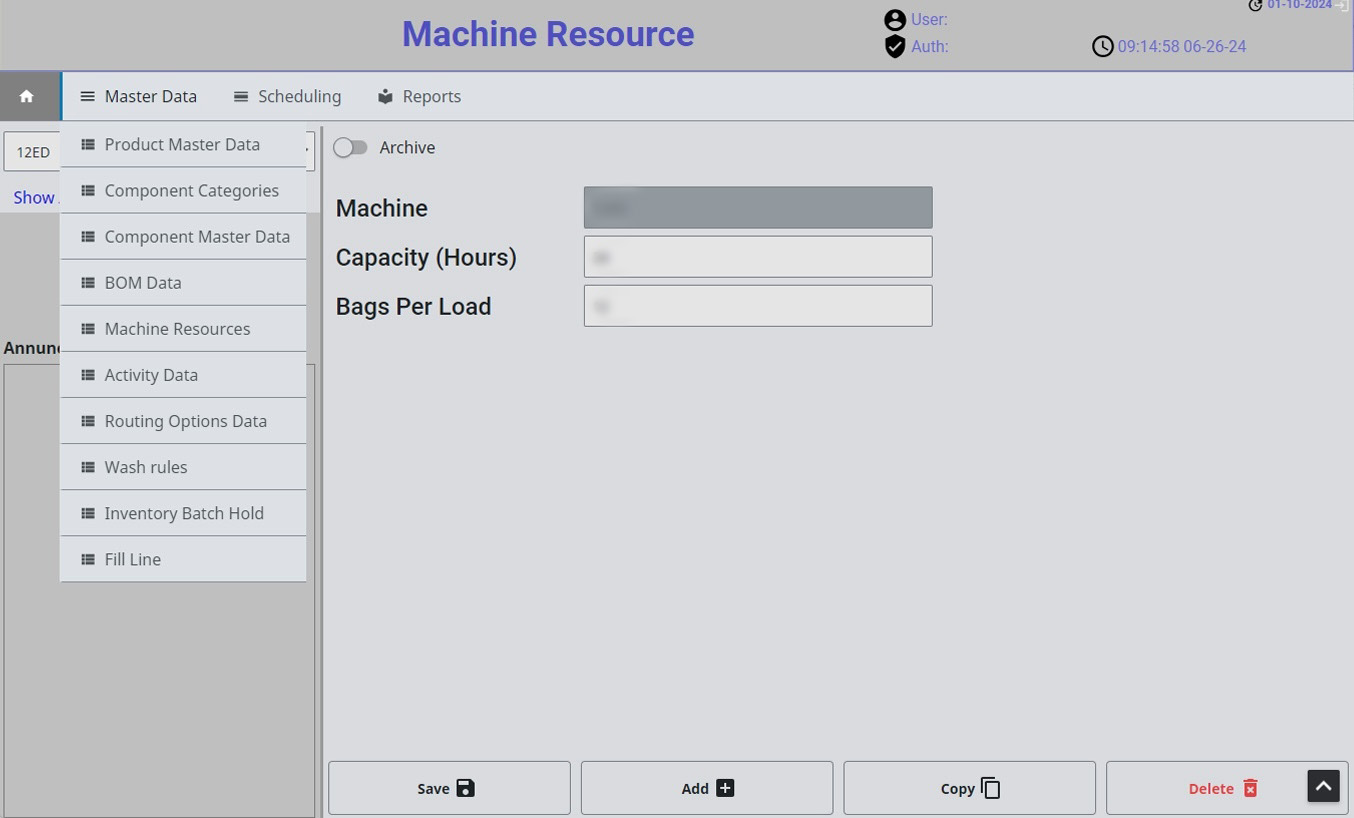

Once Sandalwood and the customer clearly defined the objective of the project, Sandalwood was able to deliver the Batch Production Scheduler: an application that would allow the customer to create a schedule of the sterilization lines that covered the requirements for the full horizon of the fill lines’ schedule as well as enable them to add products and lines over time. The core functionality of the Batch Production Scheduler included efficient component sterilization scheduling, component quantity determination, as well as reports and metrics.

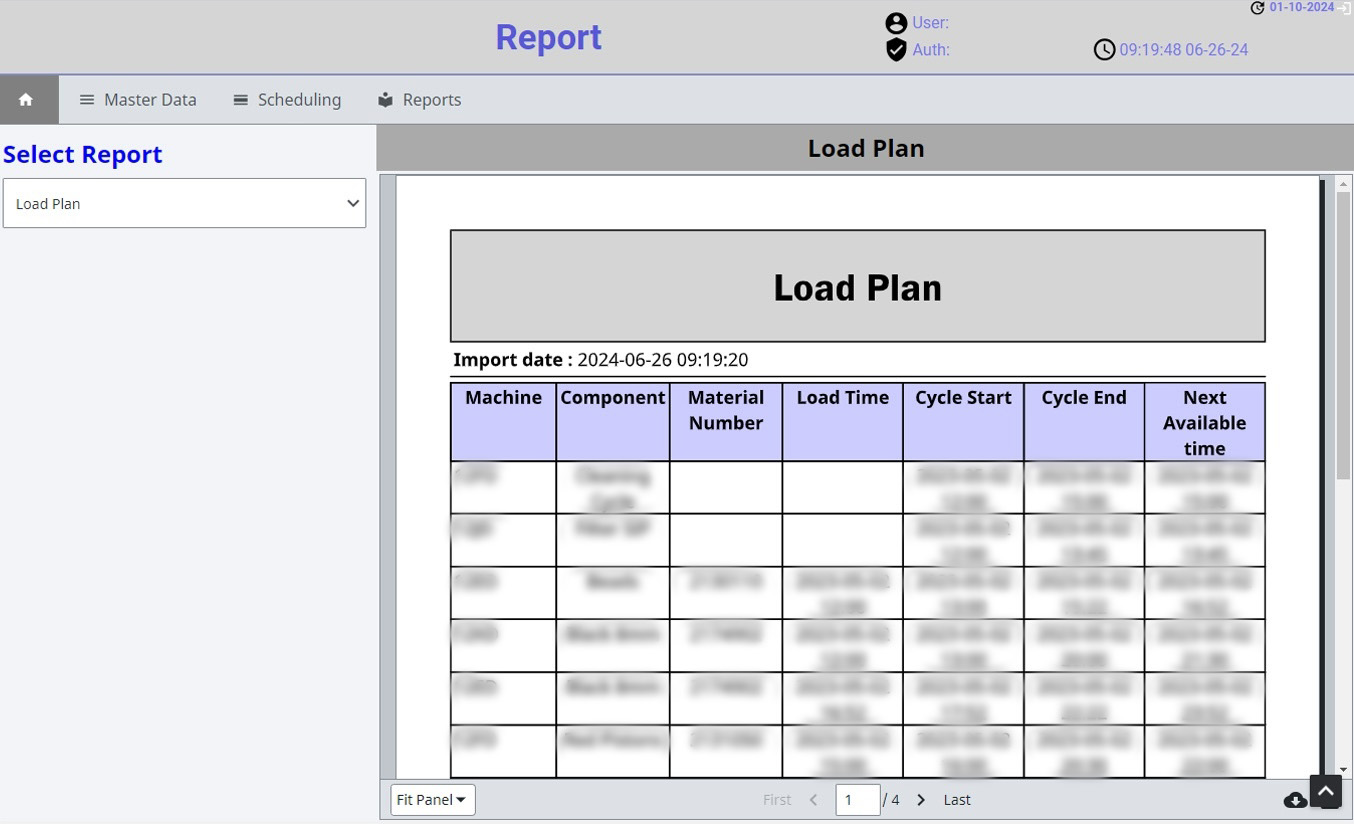

The Batch Production Scheduler transformed the customer’s production process with real-time scheduling and optimized resource utilization, leveraging Sandalwood’s algorithm to intelligently evaluate processing routes for each component, selecting the most efficient plan. The improved scheduling delivered accurate component quantities for caps, vials, and plungers based on the fill line product schedules, not only ensuring timely production, but also reducing waste and avoiding unnecessary downtime.

Beyond that, the new application delivered adaptable scheduling, allowing users to define multiple routings for component categories. This increased flexibility was especially useful as the new system introduced long-term scheduling, expanding the time window to weeks ahead. As production introduces new products and adjusts current offerings, the customer can now add new products easily, with bill of material-defined component quantities.

The new system also revealed some unexpected benefits, highlighting how difficult it was to implement changes in Excel and how little connection the data had to other applications. “Ignition was chosen as the platform to enable future interoperability starting with integration to directly query a database for inventory data,” said Sloma.

The system displays metrics for each sterilization machine’s schedule and its ability to meet fill line requirements. These detailed reports empower decision-making. “There are over a dozen middle managers and the reporting is being utilized by over three dozen people across a 24x7 operation,” said Sloma.

Sandalwood developed the solution’s UI in the Ignition Perspective Module. Perspective, which leverages mobile-responsiveness and web-based deployment, combined with the Reporting Module enables operators and managers to access reports via a web browser, eliminating the need for local files and allowing the customer to control and constrict access to specific screens and critical data.

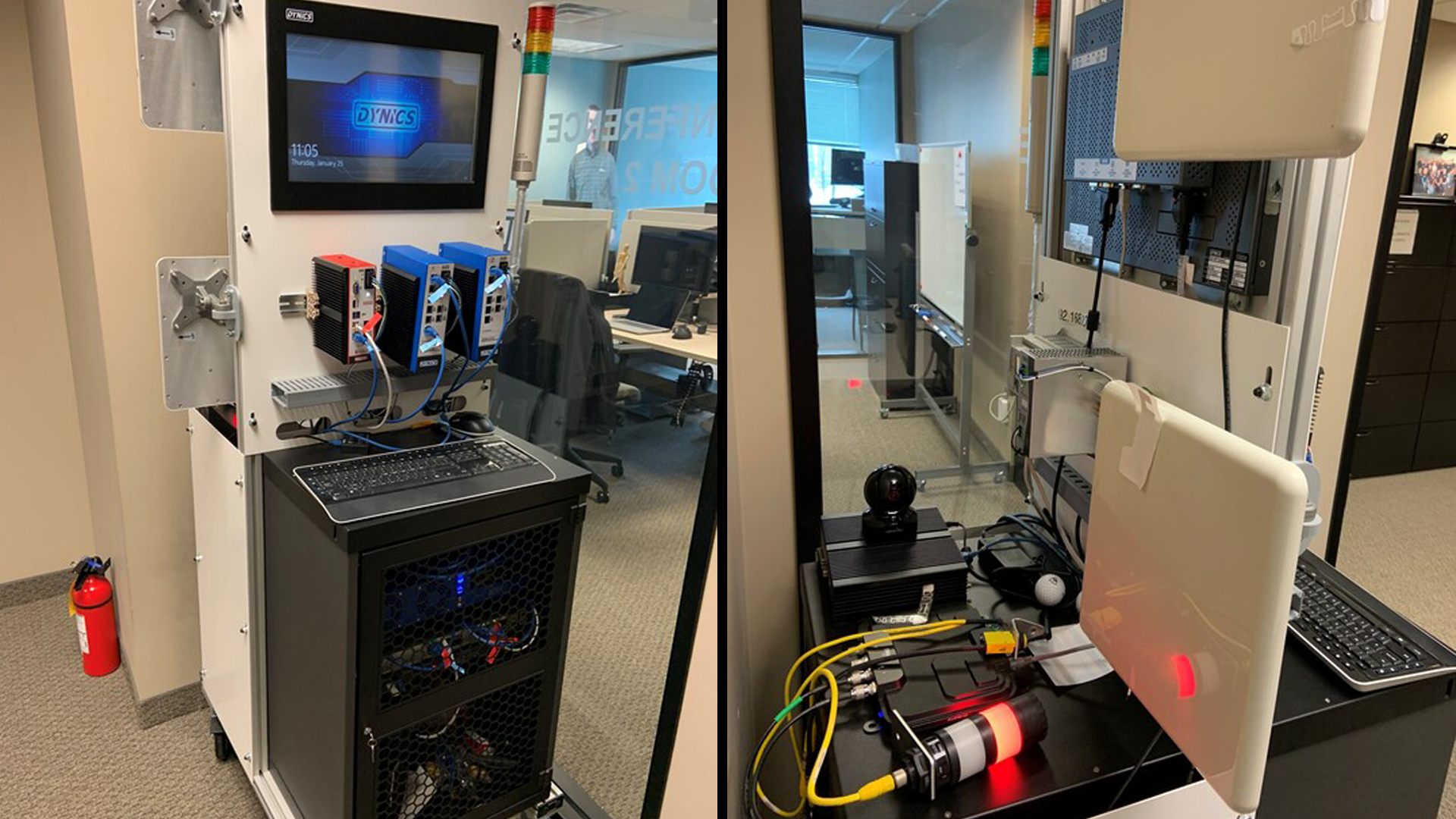

Sandalwood’s “lab on a cart” speeds up the development process

Lab À La Carte

A solution like this doesn’t come out of nowhere. At Sandalwood’s corporate headquarters in Michigan, they have a “lab on a cart” where they develop the basis for their applications. The lab consists of a two-unit rack-mounted device running two Windows PCs — one is on the corporate network while the other is connected to a manufacturing network with a firewall between the two — in addition to other devices like industrial PCs, RFID readers and antennas. Sandalwood runs a VM to simulate multiple PLCs publishing data via OPC UA with other VMs running various development environments, one of which contains a shared Ignition Gateway, MSSQL Server, and PostgreSQL.

“Ignition’s use of Python as a scripting language was also a big advantage,” said Sloma, who developed a prototype coded in Python for the scheduling algorithm, including specialized rules for how often the sterilization machines need to go through a wash cycle between production cycles or component changes. “Most of that code was able to be used within the Ignition application by the Ignition developer without significant changes. That saved a lot of development time.”

Ignition’s designer does not limit the number of concurrent developers for a single project. While Sloma was the project lead for this application, Ignition’s shared environment allowed multiple people to perform code development, reviews, and functional testing. As a result, Sandalwood was able to complete most of the development within their lab before implementing the solution in the customer’s environment. “Ignition is a breeze to install,” said Sloma. “This was handled by the customer directly. It takes more time to get the infrastructure in place (VM, network access, etc.) than it takes to install Ignition.”

Ignition’s capacity for rapid development and implementation greatly expedited the project. “The ability to start development sooner within our lab while our customers get their environment in place is a game-changer for us and allows us to deliver solutions more quickly than if we had to wait for clients to set up the resources and grant us access,” said Sloma.

Planning Long-Term

Even with the successful implementation, Sandalwood is already looking to improve the customer’s downstream visibility and advanced scheduling while utilizing the same UI template. Even though this project is not currently connected to any devices, it includes the SQL Bridge Module. Sandalwood plans to connect to a SQL database at some time in the future, with the goal of eventually obtaining the live component inventory data directly by querying the database via Ignition. The Sandalwood team hopes to utilize Ignition to develop line side user dashboarding and annunciation (Andon board) and create a digital whiteboard for the operators. Another goal is to integrate the customer’s Microsoft Active Directory for user management in place of Ignition’s built-in capability as well as their badge-in systems.

The Batch Production Scheduler has streamlined the customer’s scheduling process, and by implementing the Ignition platform, created a foundation for innovation both short and long-term.

Project Information

Created By: Sandalwood Systems Integration Group

Sandalwood Systems Integration Group provides services for manufacturers on a dedicated, part-time, project, or support contract basis. Sandalwood works with Change Agents and Operation Technology/Information Technology teams to drive improvements in their company’s digital capabilities with maximum focus and optimal yield on resources. Learn more: sandalwood.com/systems-integration.

Location Livonia, MI

Want to stay up-to-date with us?

Sign up for our weekly News Feed.