HMI: Human-Machine Interface

What is HMI, Common Uses, Trends and the Future of HMI

5 minute read

HMI Defined

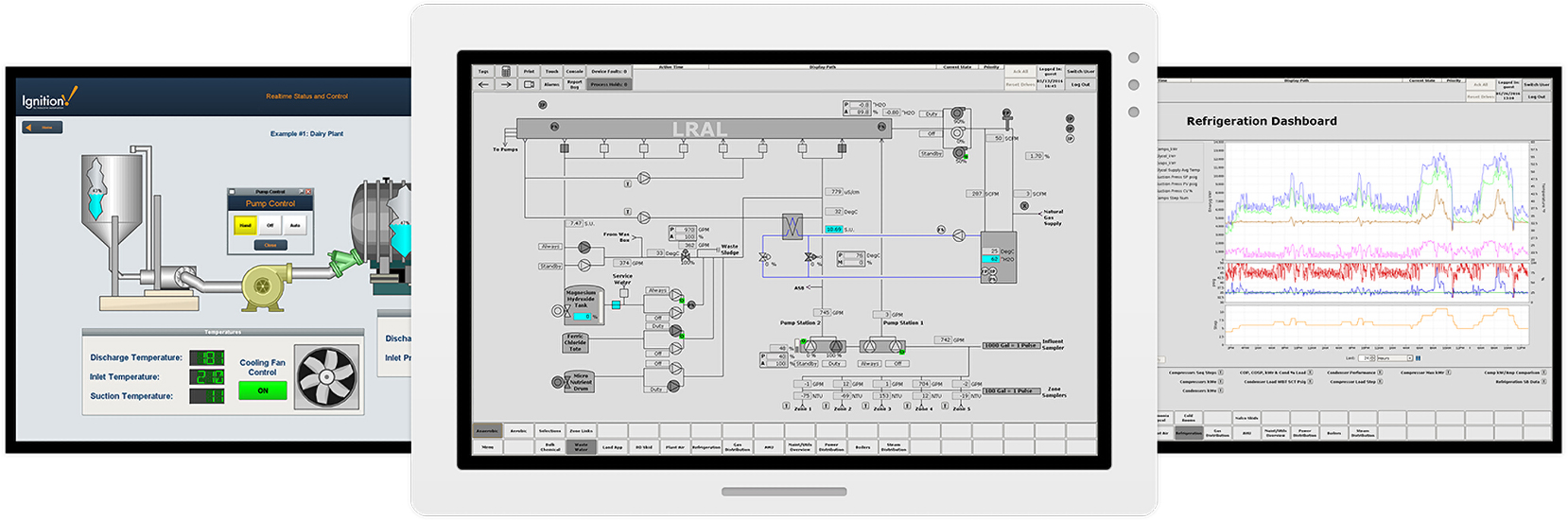

A Human-Machine Interface (HMI) is a user interface or dashboard that connects a person to a machine, system, or device. While the term can technically be applied to any screen that allows a user to interact with a device, HMI is most commonly used in the context of an industrial process.

HMIs are similar in some ways to Graphical User Interfaces (GUI) but they are not synonymous; GUIs are often leveraged within HMIs for visualization capabilities.

In industrial settings, HMIs can be used to:

- Visually display data

- Track production time, trends, and tags

- Oversee KPIs

- Monitor machine inputs and outputs

- And more

Similar to how you would interact with your air-conditioning system to check and control the temperature in your house, a plant-floor operator might use an HMI to check and control the temperature of an industrial water tank, or to see if a certain pump in the facility is currently running.

Basic HMI examples include built-in screens on machines, computer monitors, and tablets, but regardless of their format or which term you use to refer to them, their purpose is to provide insight into mechanical performance and progress.

Who Uses HMI?

HMI technology is used by almost all industrial organizations, as well as a wide range of other companies, to interact with their machines and optimize their industrial processes.

Industries using HMI include:

|

|

|

The most common roles that interact with HMIs are operators, system integrators, and engineers, particularly control system engineers. HMIs are essential resources for these professionals, who use them to review and monitor processes, diagnose problems, and visualize data.

Common Uses of HMI

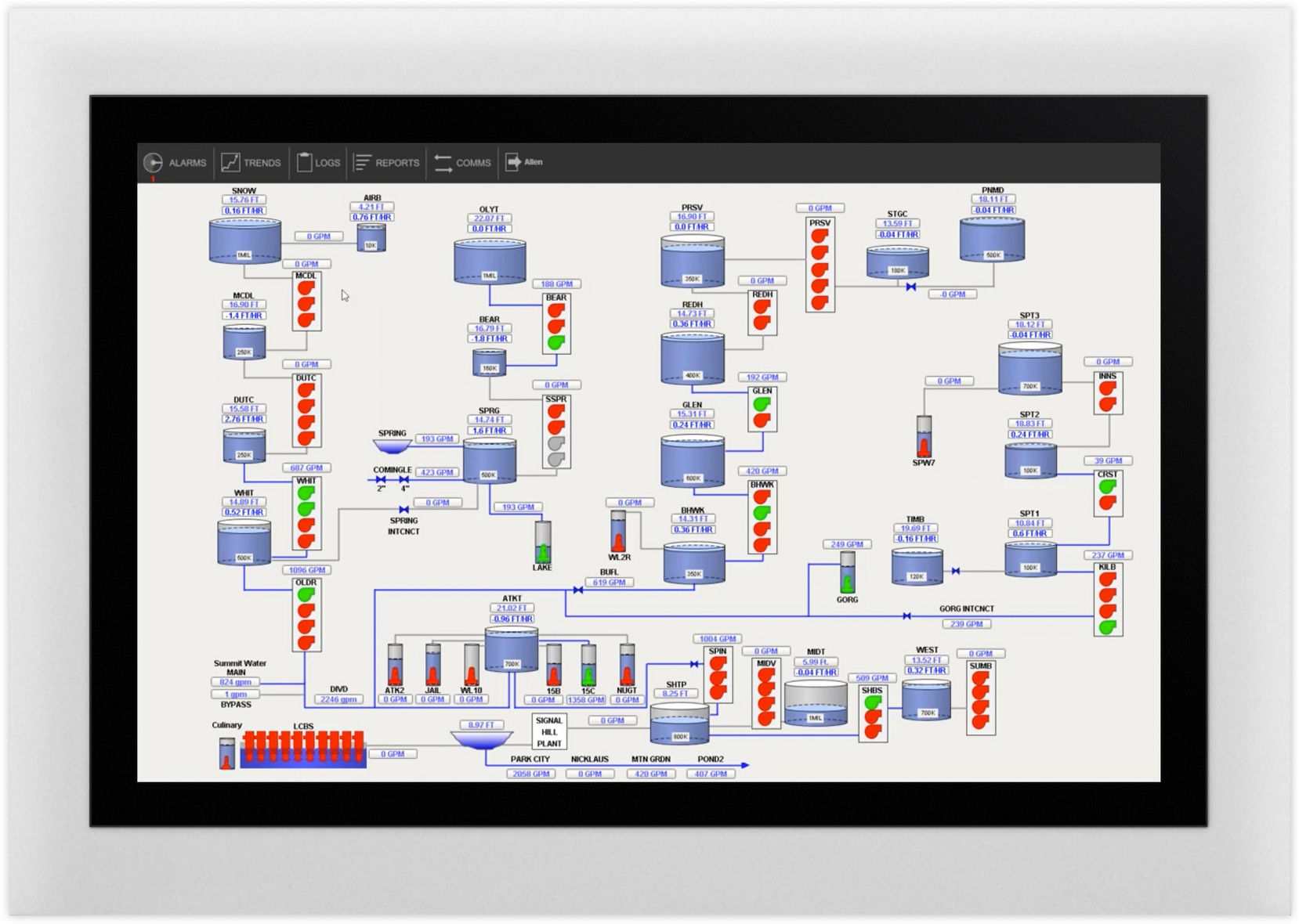

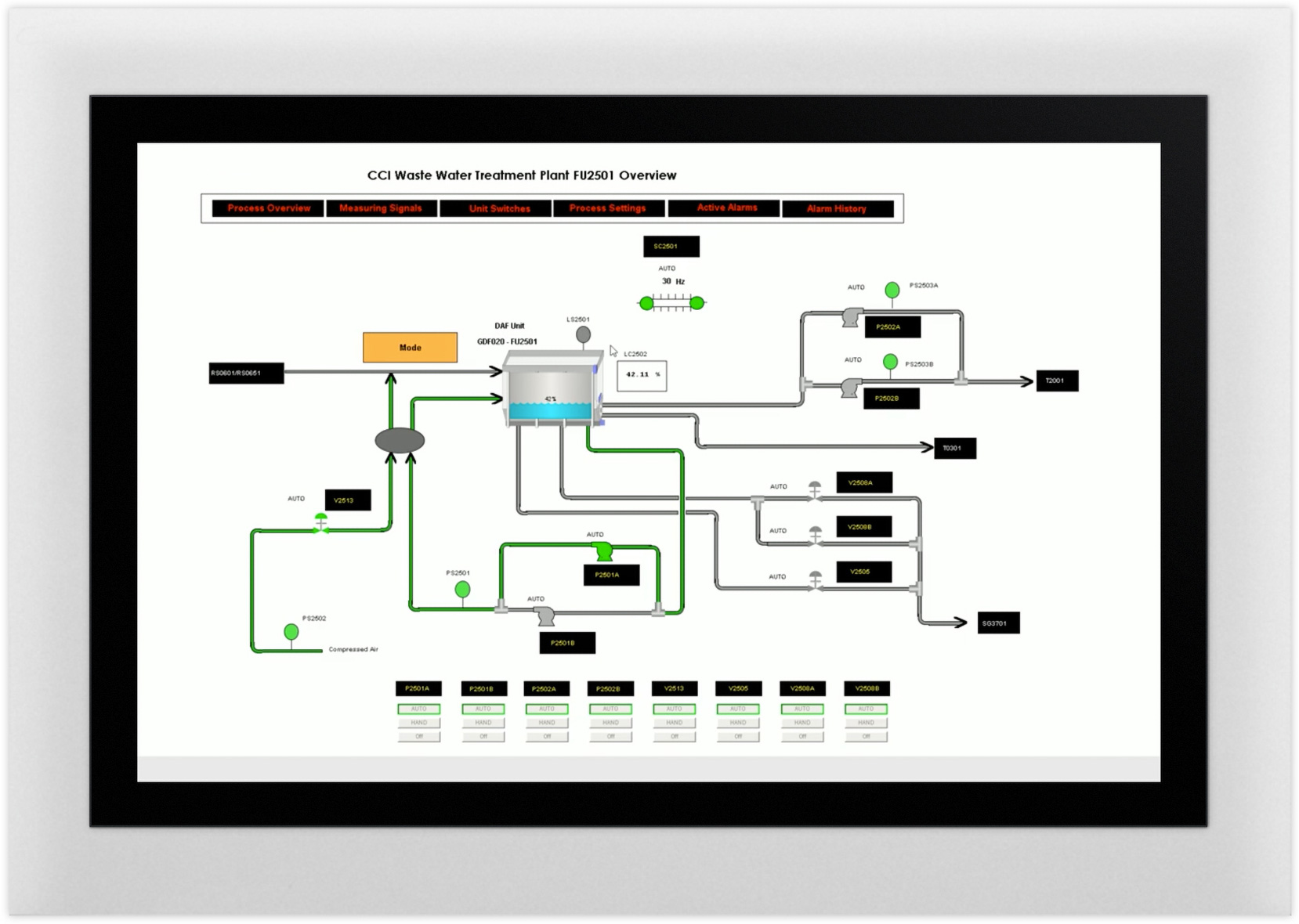

HMIs communicate with Programmable Logic Controllers (PLCs) and input/output sensors to get and display information for users to view. HMI screens can be used for a single function, like monitoring and tracking, or for performing more sophisticated operations, like switching machines off or increasing production speed, depending on how they are implemented.

HMIs are used to optimize an industrial process by digitizing and centralizing data for a viewer. By leveraging HMI, operators can see important information displayed in graphs, charts, or digital dashboards, view and manage alarms, and connect with SCADA, ERP, and MES systems, all through one console.

Previously, operators would need to walk the floor constantly to review mechanical progress and record it on a piece of paper or a whiteboard. By allowing PLCs to communicate real-time information straight to an HMI display, HMI technology eliminates the need for this outdated practice and thereby reduces many costly problems caused by lack of information or human error.

What is the Difference Between HMI and SCADA?

Supervisory Control and Data Acquisition (SCADA) and HMI are closely related, and often referred to in the same context since they are both part of a larger industrial control system, but they each offer different functionality and opportunities. While HMIs are focused on visually conveying information to help the user supervise an industrial process, SCADA systems have a greater capacity for data collection and control-system operation. Unlike SCADA systems, HMIs do not collect and record information or connect to databases. Rather, HMI provides an effective communication tool that functions as part of, or alongside, a SCADA system. For more information on SCADA, see our page, "What is SCADA?"

Developing Trends in HMI Technology

In the past decade, changing operational and business needs have instigated interesting developments in HMI technology. Now, it’s becoming more common to see evolved forms of HMI. More advanced HMI examples include high-performance HMIs, touch screens, and mobile devices, along with more traditional models. These modernized interfaces are creating more opportunities for equipment interaction and analysis.

High-Performance HMIs

Operators and users are increasingly moving toward high-performance HMI, a method of HMI design that helps ensure fast, effective interaction. By only drawing attention to the most necessary or critical indicators on the interface, this design technique helps the viewer to see and respond to problems more efficiently, as well as make better-informed decisions. Indicators on high-performance HMIs are simple, clean, and purposely cleared of any extraneous graphics or controls. Other design elements, like color, size, and placement, are used with discretion to optimize the user experience. Learn tips to boost your speed when designing high-performance HMIs here: "10 Pro HMI Design Tips: Build Screens Faster In Ignition."

Touch Screens and Mobile Devices

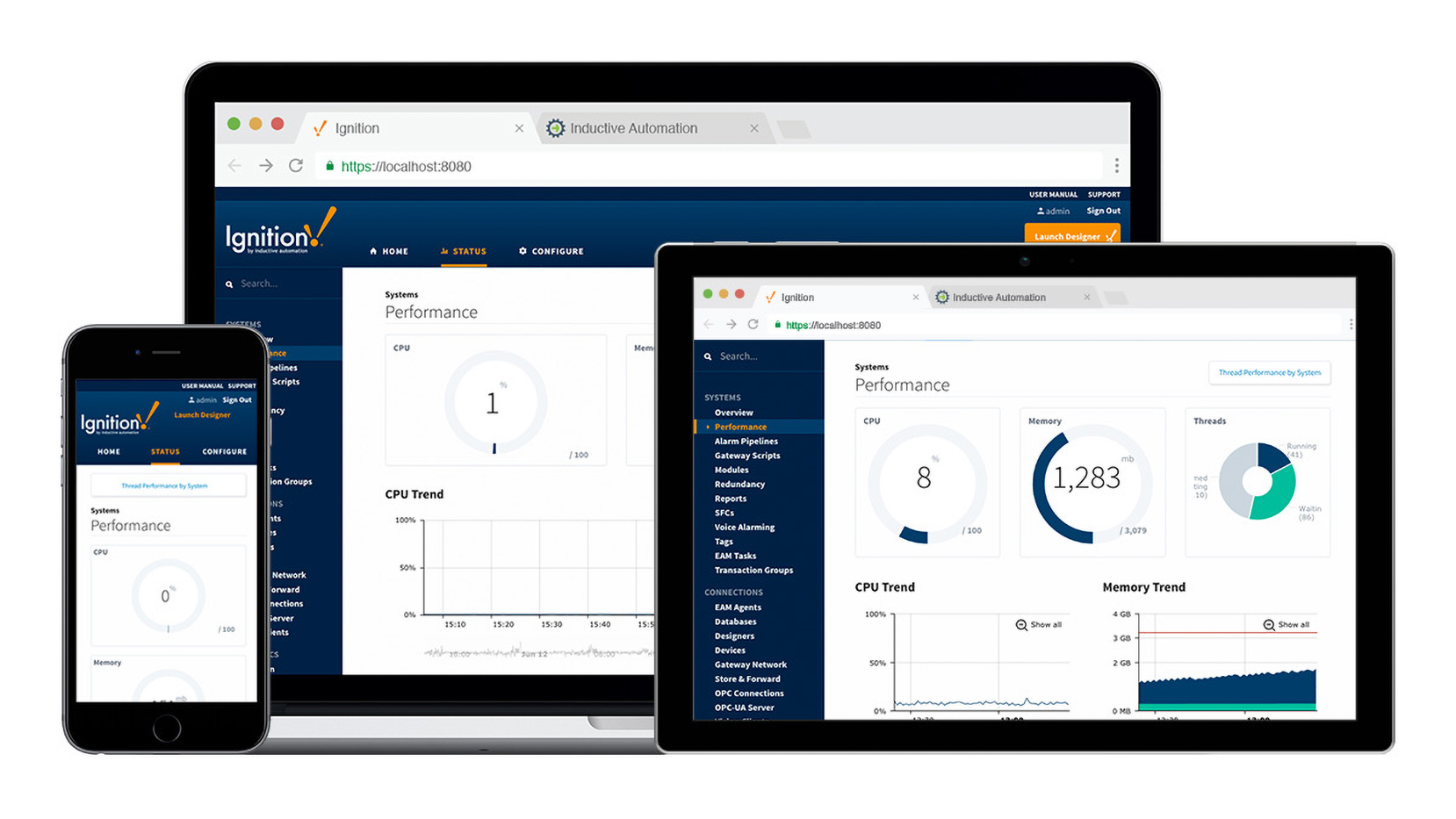

Touch screens and mobile devices are two HMI examples of technological advances that have emerged with the advent of smartphones. Instead of buttons and switches, modernized HMIs allow operators to tap or touch the physical screen to access controls. Touch screens are especially important when used with mobile HMI, which is either deployed through web-based HMI/SCADA or via an application. Mobile HMI offers a variety of advantages to operators, including instant access to HMI information and remote monitoring.

Remote Monitoring

Mobile-friendly remote monitoring allows greater flexibility and accessibility for operators and managers alike. With this feature, an offsite control system engineer can, for example, confirm the temperature of a warehouse on a portable device, eliminating the need for onsite supervision after working hours. Soon, checking in on a process on your factory floor while being miles away from the facility won’t seem like anything out of the ordinary.

Edge-of-Network and Cloud HMIs

Edge-of-network HMIs are also in high demand because they allow operators to access data and visualization from field devices. Additionally, it is becoming more common to send data from local HMIs to the cloud, where it can be accessed and analyzed remotely, while keeping control capabilities local.

Peering into the Future of HMI

On the horizon, leading engineers are even exploring ways to implement Augmented Reality (AR) and Virtual Reality (VR) to visualize manufacturing functions.

As data takes on an increasingly essential role in manufacturing, the future looks very bright for HMI. This technology may have come a long way, but its potential for growth remains virtually limitless.

Related Articles

Want to stay up-to-date with us?

Sign up for our weekly News Feed.