What SCADA Systems Need in the Modern Era

11 Must-Have Control System Features

10 minute read Download PDF

Behind the scenes of almost any industry, there’s a SCADA system at work. Ranging from simple configurations to large, complex installations, SCADA systems are the backbone of modern manufacturing, carrying out essential day-to-day functions like controlling industrial processes; notifying operators about problems that could cause downtime; monitoring, gathering, and processing data; interacting directly with devices through HMI software; and recording events.

In today’s environment, there is no doubt that SCADA is essential. However, before adopting or upgrading SCADA, there are certain features that must be considered to guarantee that a new system is powerful and flexible enough to excel in the modern era.

With the continued adoption of Digital Transformation and Industry 4.0 technology, manufacturers are using more data and analytics in their day-to-day processes than ever before. As a result, SCADA systems based on ‘90s technology are not sufficient. It’s impossible to take an organization into tomorrow if it’s stuck in yesterday.

So, when you’re choosing a new SCADA system for your organization, you should be certain it’s powerful and flexible enough to adapt to all of these unfolding changes. So how do you find that exact right type of system? Here, we’ll tell you what you need to look for in a SCADA system today.

Is Your SCADA System IIoT-Ready?

IIoT allows for access to unprecedented amounts of data. When correctly implemented, IIoT improves connectivity, efficiency, and scalability, in addition to providing time and cost savings.

Having an IIoT-capable system is critical for businesses to compete in this day and age. While the automation industry is still relatively new to leveraging analytics and AI with real-time data, IIoT architectures help to incorporate these increasingly in-demand techniques. In that way, IIoT-ready systems are poised to facilitate growth.

Questions to ask about the SCADA system:

- Does it work with IIoT standards like MQTT?

- Can it connect intelligent devices to infrastructure?

- Can it connect to the cloud or does it partially run in the cloud?

- Can it handle large-scale data collection?

Bridging the OT-IT Gap

Historically, IT and OT have been separate domains, often with different languages and procedures. But for a system to succeed in today’s landscape, there needs to be an alignment between OT and IT. Bridging the gap between OT and IT is one of the many roles of a SCADA system.

When OT and IT are aligned, it leads to major benefits like lower costs, reduced risk, standardization across the enterprise, and better decision-making. In order to successfully implement IIoT, it is important to identify technologies that are compatible with both IT and OT infrastructures.

Questions to ask about the SCADA system:

- Can it connect to any PLC?

- Can it connect to databases?

- Can it connect to your ERP system?

- Can it make data accessible to all levels of the organization?

Open Standards

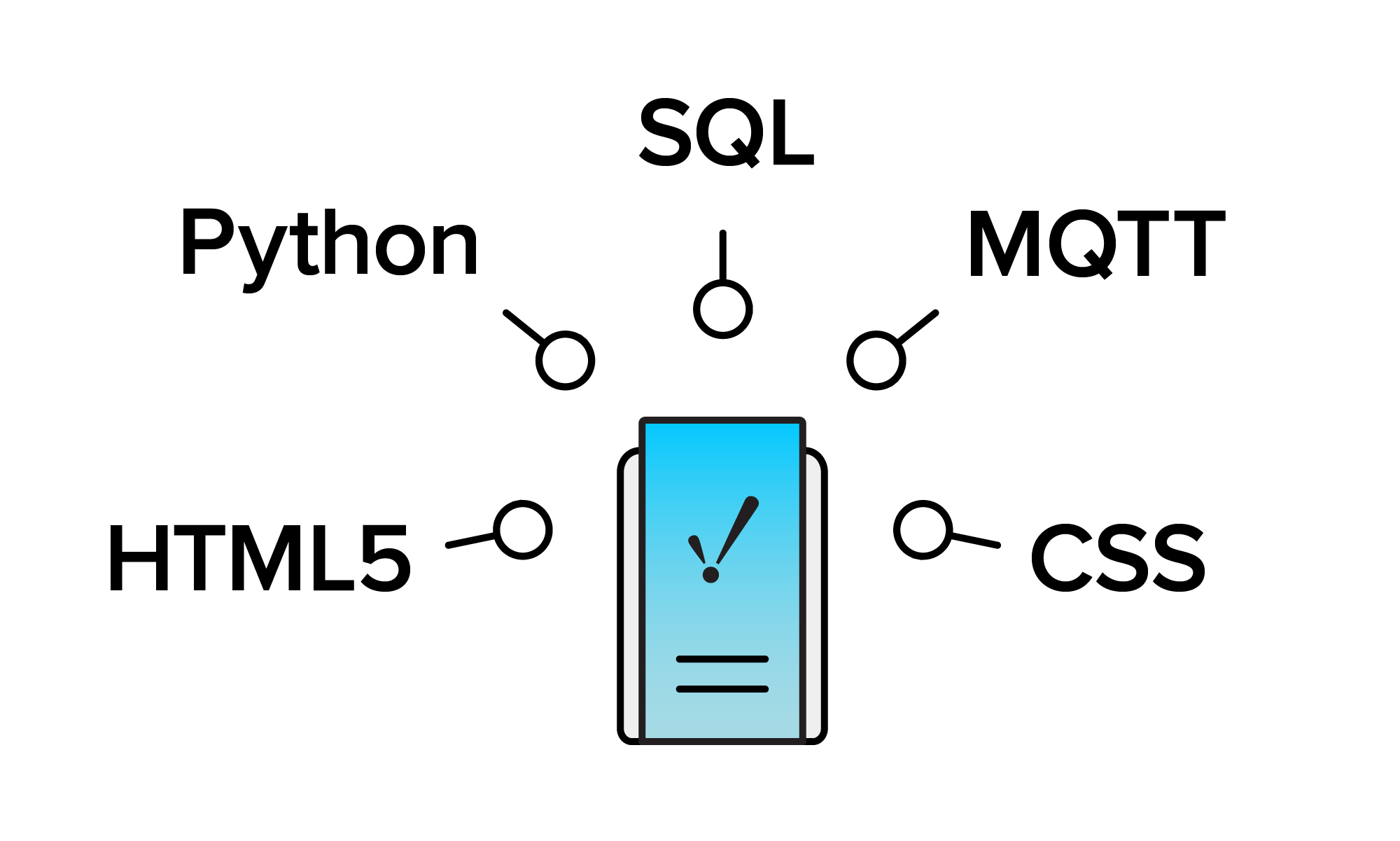

A SCADA system should be based on open standards, which promote interoperability and make integration, scalability, and collaboration much easier. Open standards are by definition vendor-neutral, offering a perfect alternative to a single vendor’s proprietary technology, which often prohibits mixing and matching pieces of software or hardware.

Open standards poise a system for moving into the future by allowing organizations to choose best-of-breed technologies instead of being locked into a specific vendor’s ecosystem.

Questions to ask about the SCADA system:

- Does it support open technologies like SQL, Python, MQTT, OPC UA, SOAP, REST, HTML5, and CSS, or is it built on proprietary technologies?

- Will it lock the system into having certain vendors?

- How difficult will it be to maintain or expand?

SCADA systems should support open technologies versus proprietary ones.

Multiple Operating Systems

A SCADA system that is compatible with multiple operating systems provides long-term cost savings, gives more options for building a system, prevents vendor lock, and causes fewer support headaches. Given that the SCADA system forms the backbone of the entire organization, this isn’t simply a nice-to-have feature—it’s essential.

Questions to ask about the SCADA system:

- Can it work with many or all major operating systems?

- If it works in only one OS and loses vendor support, how will that affect operations?

- What will it cost in time and money to switch to a different OS?

The Value of a Web-Deployable SCADA System

A SCADA system needs to be web-deployable, either on-premise or in the cloud. Cloud deployment platforms often provide greater cost efficiencies for storage and computing compared to on-prem, as well as higher-level capabilities like advanced analytics, business intelligence, and machine learning.

Additionally, organizations can have the best of both worlds by taking advantage of a hybrid cloud/on-prem architecture.

Questions to ask about the SCADA system:

- Can it be accessed from a local network?

- What about from an Android device or an iPhone?

- Can it run full-featured in a web browser or mobile?

- Is it only a limited version that is unable to run the entire application?

- How long does deployment take? Is it instantaneous?

- Can it be deployed in the cloud in addition to on-prem, and can those systems work together?

- Does it provide a quick way to put OT data into cloud services like AWS and Azure?

A SCADA system needs to be web-deployable, either on-premise or in the cloud.

Made for Mobile

In the modern era, the role of a SCADA system is vastly different than it was in the ‘90s. There has been a huge proliferation of mobile devices over the past 15 years; therefore, today’s SCADA systems should be equally functional on mobile as well as desktop.

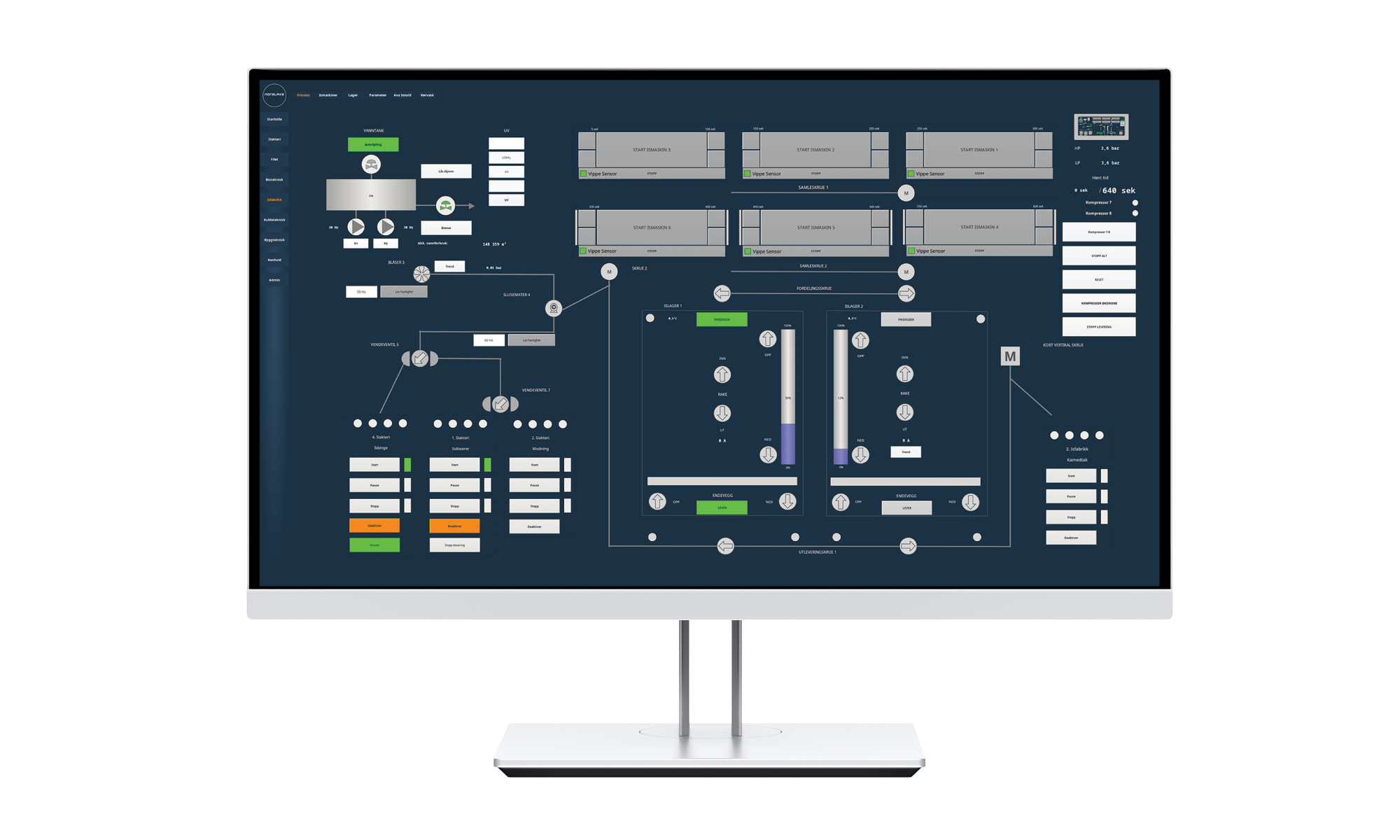

Having a SCADA system that leverages HTML5-based components is critical for building out operational dashboards. You want a system that provides HMI on the plant floor, yet also makes OT data instantly available so that operators can immediately respond to problems and make informed decisions based on real-time data, wherever they are.

Questions to ask about the SCADA system:

- Does it work equally well on mobile, desktop, and plant-floor screens?

- Does it offer a first-class solution for building mobile industrial applications?

- Do the HMIs look good on any size screen?

- How advanced is the mobile component?

- Is it built “mobile-first” from the ground up or is the mobile element tacked on?

Remote Monitoring and Process Control

A SCADA system that enables remote monitoring expands the reach of real-time information beyond the control room to remote users. Operators at any location need access to the same information as the control room, sourced from a common ecosystem that is agile and scalable.

Remote process control allows for immediate action, reducing the number of personnel on-site and the need for travel. It lowers operational costs, improves worker safety, and speeds up response times for incidental alarms.

As COVID-19 has accelerated the move toward remote operations over the last year and a half, remote process control has become a permanent shift for many organizations.

Questions to ask about the SCADA system:

- Can it easily set up a remote connection to anything inside the enterprise?

- Can it increase the number of tags and connections without going over budget?

- Can it easily collect data from the field and from edge devices?

- Can it add capabilities like reporting, alarming, and enterprise administration to manage a fleet of installations?

Edge-of-Network Capabilities

According to an Eclipse Foundation survey in 2021, the adoption of edge computing technologies is accelerating alongside the adoption of IIoT, making it one of the fastest growing areas of industrial automation. Edge computing pushes polling closer to the source, covering more territory while reducing latency, thereby improving security and collecting real-time data more reliably.

Edge computing creates many powerful solutions, particularly in a geographically distributed system. It standardizes and adds context at the edge. For example, a tag can be recognized as more than just a Modbus address; it can be identified as, for example, a pressure transmitter with metadata that identifies its location upstream or downstream of the pump.

In larger IIoT ecosystems, edge computing allows data to transmit from the edge through the SCADA system and into the enterprise environment for consumption. Additionally, it opens up the ability to integrate information beyond industrial protocols, taking flat files, PDFs, and cameras and converting them into real-time information to assist with analytic and business decisions.

Questions to ask about the SCADA system:

- Does it extend data collection, visualization, and system management to the edge?

- Can it add functionality like local HMIs, field devices, data synchronization, and publication of field device data at the edge?

Scalability

In today’s world, it’s not a question of whether conditions will change, it’s a question of how and when conditions will change. Therefore, when evaluating how future-proof a SCADA system is, you must consider its ability to grow and scale. An ideal system should allow an organization to build any kind of architecture, whether it’s a simple data logger, a network that stretches over a wide geographic area, or anything in between.

Questions to ask about the SCADA system:

- How challenging will it be to scale the system out?

- How many kinds of architecture can be built with it?

- Are there options for different architecture types?

- Can it be deployed effectively at one site, multiple sites, to the cloud, and any combination thereof?

- Can you add redundancy and is redundancy easy to add?

- Can it manage data and projects from one central location?

Cybersecurity is at the top of everyone’s minds.

Cybersecurity

Unfortunately, attacks on industrial targets are increasing in various forms, whether it’s phishing, malware, ransomware, or data breaches, to name just a few. No software is 100% secure, but having software with modern security features is vital.

A few years ago, the OT network was either siloed off from the rest of the system or secured with firewalls. There was little emphasis placed on security, and some organizations even kept the OT network open to the rest of the IT network.

It is important to address security considerations for any modern SCADA system, especially encryption like TLS 1.2 or 1.3. Leveraging the same encryption that banking websites use can make a big impact in keeping an organization secure.

In the case of a network compromise, there should be protections in place to prevent bad actors from accessing the SCADA system and doing any damage. This means protecting all ports as well as any internet connections that utilize IIoT technology. It is critical that a system has security at the forefront, as something that is a core piece of the system overall.

Questions to ask about the SCADA system:

- Does it support widely used encryption protocols like SSL and TLS?

- Does it support federated identity providers?

- Does it support two-factor or multi-factor authentication?

- Does it have a model for user permissions?

- Does it follow the Purdue Model?

Unlimited Licensing

For a SCADA system to truly excel in the modern era, it needs an unlimited licensing model. Traditional SCADA licensing requires payment for every client and tag added—1-10 tags being X number of dollars; 50-100 being Y number of dollars—making it difficult if not impossible to add sensors or devices after the fact.

With unlimited licensing, the number of tags is only limited by what the hardware can support, moving the range of tags into hundreds of thousands before multiple servers and licenses are required. Unlimited licensing also makes it possible to expand the system without constraint, which facilitates innovation, opens up possibilities, and frees engineers and designers to implement the best possible solutions.

Questions to ask about the SCADA system:

- Is it licensed by clients and tags or is it licensed by the server?

- Will it cost more to add those clients, tags, and connections?

- Will scalability be affordable under the licensing model?

- How will the licensing affect or limit the system’s overall performance?

SCADA Software for the Modern Era

Ignition by Inductive Automation is an industrial application platform designed to have all of the key features needed for today’s changing world, empowering your organization to create a future-proof SCADA software system that is ready for the modern IIoT era and beyond.

Appeared in the December 2021 issue of Automation 2021: Cybersecurity & ICS Modernization, an ISA.org publication.

Want to stay up-to-date with us?

Sign up for our weekly News Feed.