Table of contents

- Why Present-Day SCADA is Actually Old

- Experience The New SCADA

- Reason #1: Leverages Modern Technologies

- Reason #2: Increased Flexibility

- Reason #3: Database-Friendly

- Reason #4: True Real-Time Analytics

- Reason #5: Rapid Installation & Development

- Reason #6: Platform Independence

- Reason #7: Unlimited Licensing

Why Present-Day SCADA is Actually Old

While technology has always changed, you’ve probably noticed that the changes have become bigger and faster in the last few years. Currently, a wave of new technologies is driving major disruption in the manufacturing sector. Big Data and analytics, the Cloud, the Internet of Things, mobile technologies and social technologies are changing our world and will affect how the successful manufacturers of tomorrow operate.

But there’s another change: many industrial automation professionals are experiencing a whole new level of capabilities and freedom, and even enjoying their work like never before. They’re able to think about all of the things they can do with their systems instead of all of the things they can’t. This has a major impact because when people can enjoy their work, real innovation happens on the ground floor and businesses succeed.

Where’s the Excitement?

For years now, many if not most SCADA (supervisory control and data acquisition) users have felt very limited by the technology. They’ve come to perceive it as an obstacle to work around rather than a flexible tool they can shape to their needs. The underlying problem is that what most people today think of as current SCADA technology is actually based on decades-old technology. Despite its many uses, old SCADA technology holds its users back from operating at their full potential or innovating for the future. Although enterprises need modern, flexible solutions to sharpen their competitive edge, the SCADA industry continues to sell cumbersome and expensive software packages.

The lack of technological progress in SCADA is more than frustrating; it threatens the competitive viability of SCADA users going forward. For example, a company that needs to improve its processes will be hampered by the lack of real-time data analytics. Or, it may be forced to endure an expensive and time-consuming upgrade of its SCADA system because the operating system it ran on was phased out. It might need to develop some new displays but find it next-to-impossible to do in their current SCADA software. Or, a company might need to add more workers onto its SCADA system but be unable to afford the increased costs that would result. These are just some of the ways that old SCADA proves to be a hassle and a hindrance to enterprises trying to succeed in the 21st century.

Experience The New SCADA

“User experience” or “UX” has been a tech-world buzzword for more than a decade now. In the broad sense of the term, UX refers to the sum of a customer’s thoughts, feelings and interactions with a given company, product or service. Don’t frustrated SCADA end users and integrators deserve a better user experience? Indeed, they require it in order to succeed. It’s become clear that late-20th-century SCADA software will no longer suffice. For a new user experience, today’s enterprises need a new SCADA solution that’s made for the 21st century.

What’s needed is more than an update to SCADA software, but an entirely new approach to the technological, licensing, business and ethical aspects of SCADA software. Essentially, the entire experience around SCADA software needs to be reinvented from the ground up. This new paradigm – The New SCADA – creates a user experience that not only eliminates old SCADA pain points but builds entirely new possibilities.

The New SCADA is more than a wish or an idea; many integrators and system engineers are experiencing it with a software platform called Ignition by Inductive Automation.®

7 Key Advantages of Using The New SCADA

In the rest of this paper, we will examine the most compelling reasons why old SCADA holds companies back, and how The New SCADA solves those problems.

Reason #1: Leverages Modern Technologies

Old SCADA is Stuck in the 1990s

Many of the issues with old SCADA systems can be attributed to the fact that information technology (IT) systems have continued to advance while SCADA’s progress largely stalled out in the 1990s.

While the 90s may not seem that long ago, technology has progressed enormously since then. During much of that decade, the Internet was still catching on among businesses and consumers. Dial-up modems, large cell phones and personal digital assistants (PDAs) were still commonly seen then. Since that era, the web has taken on a central role in business and society, and web-connected smartphones and mobile devices are becoming more prevalent by the day. In our increasingly fast-changing world, how can decades-old technology be considered an acceptable option?

The New SCADA is Web-Deployable

In the 21st century, we need SCADA software built with the Internet in mind. The New SCADA brings all of the speed, performance and connection of the web to the world of SCADA. You can download and install it in a few minutes, without installing a driver. You can launch and make changes to clients instantly with one click.

The New SCADA can be set up on a cloud network or a local network. You can launch it to any computers or devices with a web browser, such as smartphones and tablets, so you can connect to your system not just on the plant floor but practically anywhere. The mobility of The New SCADA gives users the ability to access live data from throughout the enterprise, anytime, anyplace. This leads to a much smoother user experience and a much more productive system.

Reason #2: Increased Flexibility

Old SCADA Isn't Integrated

To build something that can stand the test of time, you need to start with a sturdy infrastructure. But instead of building software from the ground up, old SCADA companies cobble together separately made pieces of technology and then market them as a single software package. The kludgy nature of old SCADA software shows in its performance. Unsurprisingly, the disparate pieces within old SCADA systems don’t work together seamlessly, and it’s hard to rely on the system as a whole. Trying to upgrade these systems means adding newer technology on top of 90s technology; a Frankenstein-like approach of attaching new limbs onto a dying core and then hoping that everything will work out (and we know that Frankenstein’s story didn’t end well).

Users today need the confidence that they can expand or scale back their system quickly. But old SCADA systems are not easily expandable: the more you try to customize or grow them, the more complicated they become. How are you supposed to know what you’ll need to add in the future or how will it affect the rest of the system? How much can you innovate when your SCADA setup is so unmanageable that you have to alter your unique processes to conform to it?

The New SCADA is Modular

One of the most remarkable aspects of The New SCADA is its unified modular architecture. A modular system is made up of components that can be added, changed or removed without impacting the rest of the system.

A biological example of modularity is the cell. As multicellular organisms develop, cells divide into groupings that make up different developmental modules. Within individual cells, there are functional modules which all perform separate biological functions. Some scientists have theorized that modularity is critical to evolution. It’s fitting then that the next evolution in SCADA software is based on modular architecture.

Inductive Automation has cross-pollinated modularity into SCADA to create a truly unique platform that can be easily adapted to changing needs. The New SCADA’s unified platform performs the most essential functions while allowing users to add specialized functions through a variety of HMI (human machine interface), SCADA, MES (manufacturing execution system), and ERP (enterprise resource planning) modules which work together seamlessly. Users can add SCADA features such as charts and tables, mobile access, voice notifications for alarms, the ability to create sophisticated logic systems, and more. They can also add MES functions such as track-and-trace, recipe management, and real-time SPC data, as well as providing the benefits of ERP and MES integration.

However, The New SCADA is more than a first-rate HMI, SCADA, MES, and ERP solution; it also provides a rapid development environment for building any type of automated system you need. It’s not uncommon for users who become familiar with Ignition’s full capabilities to develop customized applications and systems that would be impossible with any other SCADA program. Companies can use it to tie all of their assets together, display various types of data, track production and work-in-progress, analyze raw materials, eliminate paperwork on the plant floor, track sales information and other CRM functions, and much more.

The modularity of The New SCADA allows you to buy exactly what you need when you need it, and to feel the assurance that your system will continue to work smoothly as you add and make changes to it.

Reason #3: Database-Friendly

Old SCADA is Not Database-Friendly

In an increasingly data-driven world, there’s a lot of focus on managing larger datasets and getting more value out of them through analysis. Data needs to flow freely, but in many enterprises it doesn’t. One reason is that most SCADA software only communicates with a specific type of vendor-endorsed database. Communicating with a non-endorsed database requires paying additional charges and may require separate database connectors.

Old SCADA software usually doesn’t work well with SQL databases, even though they are the most commonly used type of database. This can leave a gap between time-series and other useful enterprise data that’s typically stored in SQL databases. The result is that data stays locked down instead of flowing throughout the enterprise, a situation that limits efficiency and innovation.

The New SCADA is Database-Centric:

As the first database-centric SCADA software solution, Ignition has pioneered the connection of databases with SCADA. Instead of limiting communication to a specific type of database, it allows unlimited database connections with most any type of database, including SQL. By connecting with SQL databases, Ignition allows users to put time-series data into a relational database, reap the benefits of ERP, SCADA, and MES integration, and log historical data from a SCADA system in a SQL database.

The New SCADA also supports any database server and enables users to develop database applications. Users have the freedom to bridge different types of data and make all of it more useful. The database-centric nature of The New SCADA makes the user feel much more empowered because they can gather all of their data into one place.

Reason #4: True Real-Time Analytics

Old SCADA Data Isn't Accessible in Real-Time

As the pace of business accelerates, getting data in real time becomes more important. Old SCADA software may display plant-floor data in real time, but getting a fleeting glance at this data isn’t the same as seeing it in context or gleaning insight from it.

Without the ability to easily gather real-time and historical data from various sources, it is difficult to put your data into context. This makes it difficult to observe trends, see who did what and when, monitor performance, or improve output over a longer time period.

The New SCADA is Real-Time

The New SCADA helps you handle the ever-increasing volume, variety and velocity of data, which are also known as “the 3 V’s.” But just as importantly, it helps you unlock the value of data, which we can think of as the “4th V.”

With The New SCADA, it’s easy to obtain real-time and historical data from a variety of sources, put it all into context, and redistribute it. This helps enterprises to get more data seen by more people at more points throughout the process. When an operator gets plant-floor information in real time, they can take immediate action. Real-time control and monitoring makes it possible to quickly see and analyze the status of a facility, and get instant alarm notifications and reports. Now that data is flowing freely between clients and servers instead of being isolated in different systems, key individuals can get a real-time overview of all their data, and the entire company can get more value from it.

The New SCADA not only shows you data in real-time but it helps you make data meaningful. “When you have that data, that’s just part of the problem. Figuring out what to do with that data and making it meaningful is really the important part of the problem,” says Charlie Hendrixson, director of automation services for Miller-Eads Automation. “And with Ignition you have that seamless process, with transaction groups and understanding how you want that data collected, and then pulling it back out and figuring out a way within Ignition to display it and there’s many different ways to display that data, whether that data is going to be used in MES or used for real-time live trends for them to look at their process and see how it’s going, really the sky is the limit as far as how you are going to utilize that data.”

Reason #5: Rapid Installation & Development

Old SCADA is a Timewaster

Everyone knows that outdated technology is slower, and you’re constantly reminded of this fact when working with old SCADA. When you go to install it, you can’t download it today. Instead, you usually have to wait for the CD to arrive in the mail. Once you have the software, it takes hours, days or weeks to install.

The time loss doesn’t stop there. When you need to add functionality or make configuration changes, you have to shut the system down and lose precious production time. Deploying applications to clients in old SCADA requires taking the clients offline. Designing with it takes up a lot of time, especially since old SCADA doesn’t support concurrent development. Trying to develop in old SCADA is somewhere between very time-consuming and near-impossible. How can anyone keep up with the fast pace of business when their SCADA software is constantly slowing them down?

The New SCADA is Faster – Much Faster

As mentioned earlier, old SCADA is still `90s-based, and technology that was considered fast enough then is now agonizingly slow. The New SCADA speeds things up: instead of taking hours, days or even weeks to install, it can be downloaded and deployed in a matter of minutes. Instead of limiting the number of active simultaneous developers, its unlimited designer clients allow multiple developers to work on the same project concurrently. You can add functionality or make configuration changes almost instantly with hot-pluggable modules, without shutting down the system. When you upgrade the server, all clients update instantly.

All of these time savings add up to an exponentially faster SCADA system.

Reason #6: Platform Independence

Old SCADA is Platform-Dependent

Most SCADA software is made to run on a certain, proprietary operating system, usually one made by Microsoft. This puts users through the stress of Microsoft’s frequent security issues, patches and upgrades, and leaves them vulnerable whenever Microsoft terminates support for one of its operating systems. For example, when Microsoft ended support for Windows XP in April 2014, more than 15 percent of midsize and large enterprises were still using it at the time, according to estimates by Gartner Inc. Companies using Windows-based SCADA software were put into a no-win situation of expensively upgrading their OS or taking their chances with the security risks of an unsupported OS.

The New SCADA is Cross-Platform

The New SCADA is the first SCADA software built entirely on the Java programming language, which makes it cross-platform compatible and easily web-deployable. Cross-platform, Java-built Ignition spares its users from dealing with the OS upgrade cycle because it works with every modern version and service pack of Windows. The New SCADA can run on practically any OS, including open-source, giving users many more options in the software and hardware they use.

With the flexibility of choosing from various platforms for SCADA, enterprises can get the separate software systems under their roof on “the same page.” Ignition can also be connected to a wide range of devices and works seamlessly with any MES or ERP system, allowing data to flow through an entire organization. This makes it possible to connect the plant floor to the ERP level, so the whole enterprise can work smarter.

Reason #7: Unlimited Licensing

It’s Time for New Technology

Old SCADA is outdated, doesn’t work well with databases, lacks real-time data analysis, is slow to set up, and has a pieced-together platform that is too limited for users’ needs. The technology of old SCADA is fading and is in desperate need of disruption.

“If you think about the technologies we had 20 years ago, which most of the systems that are in place are based off of now, the technology was different: there were no cell phones, and the Internet was just coming out, so we didn’t have then a lot of the issues we have now, such as security, remote access, ease of access; the entire architecture was completely different. Instead of having a single server connected to a host of local PLCs, you can now have a host of servers connected to thousands or tens of thousands of devices. So naturally with that progression in technology, the architecture and technology of SCADA both need to change, and Ignition provides that much-needed change,” says Kyle Chase, systems integrator and CEO of Kymera Systems.

In addition to its technological flaws, the licensing model of old SCADA is holding users back.

Old SCADA Licensing Limits Success

Licensing SCADA software based on the number of tags, clients and connections that the customer uses: this is the business model that the big SCADA software companies are built on. But while this model may benefit the software maker, it doesn’t work so well for the user because the larger their system grows, the more money the user will have to spend.

In addition to being very expensive, SCADA licensing endangers the user’s success by hurting their ability to innovate. Think about it: when you have to pay for each piece you need to add to your system, you have less flexibility to grow, adapt and scale to keep up with today’s fast-paced business environment.

Old SCADA prevents enterprises from becoming more data-driven by, in effect, limiting the number of people on the system. The old licensing model compels most users to either limit the number of people who use the system or the amount of data the system processes. This prevents users from reaping the maximum value from their system, and it stifles communication and collaboration.

“We have installed or augmented systems from almost every major player in the market, and we seem to always find ourselves working within certain limitations, be it licensing or even the technological shortcomings of the product,” says Hendrixson. “In the end, the customer suffers because we can’t give them the product they really want because we don’t have the right tools at our disposal. The licensing model of legacy software is the first thing that comes up when you want to expand a current project, be it tag-based or screen-based licensing. Licensing is usually the biggest obstacle to overcome,” he says.

Ignition is The New SCADA

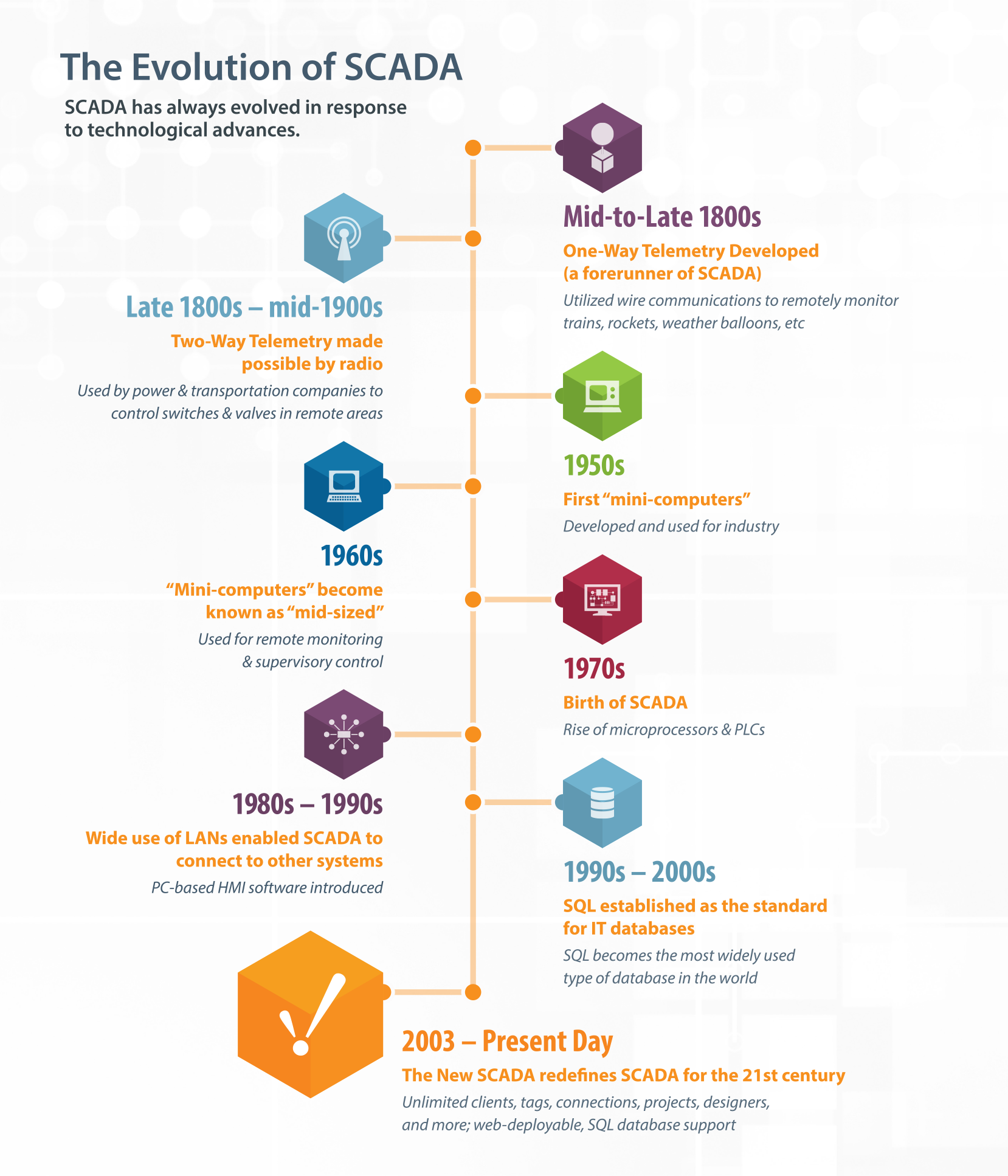

From wire-based telemetry to PC-based HMI software, the evolution of SCADA technology teaches us that those who want to succeed in this field must embrace and incorporate new technologies into their processes (see page 9 for more about the history of SCADA). The builders of The New SCADA understood this and set out to not merely improve SCADA software but to design a fundamentally different solution.

The New SCADA is the next step in the evolution of SCADA: a turning point where an aging technology was ushered into the Internet age and given new life. While the elements that comprise The New SCADA are sophisticated, the guiding idea behind it is clear and simple: to build SCADA software for the 21st century.

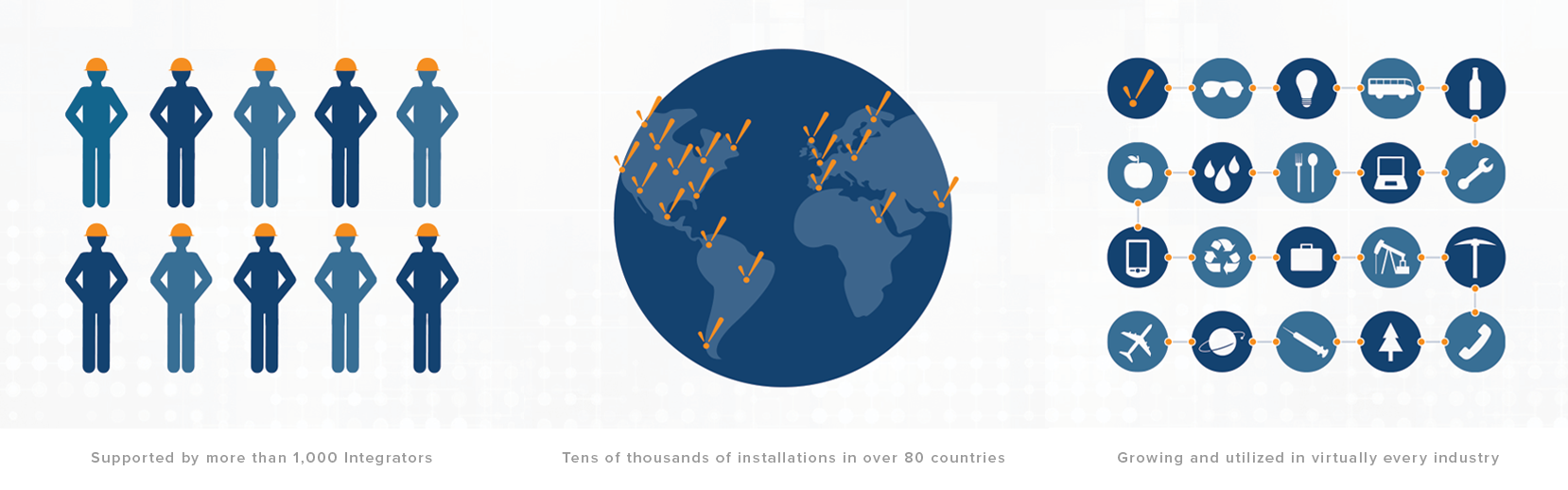

Ignition was launched in January 2010 and has already made a serious impact in the SCADA software industry. It has been installed in tens of thousands of facilities in more than 80 countries. It is supported by more than 1,000 integrators and used in a growing number of industries, including food and beverage, oil, gas, packaging, pharmaceutical and water / waste water. It is used by 30% percent of companies in the Fortune 100 and 20% percent of companies in the Fortune 500 to build HMI, SCADA and MES systems, as of 2014.

As more enterprises adopt The New SCADA, they experience fewer obstacles, discover better ways to run and grow their operations, and become part of a global movement that is permanently changing the course of industrial automation.

Want to stay up-to-date with us?

Sign up for our weekly News Feed.