Resources

Browse our ever-expanding library of useful articles, case studies, videos, webinars, and more.

Featured

In 2022, Döhler South Africa realized they were reaching capacity in their production facility, an impasse that countless growing companies have reached. The question always becomes: make do with too-cramped quarters or invest in a long-term solution?

Döhler — a multinational company that manufactures fruit juices, compounds, flavors, emulsions, and concentrates — chose the latter for their new facility, which specializes in blending and secondary transformation. Located in Paarl, South Africa, the new plant adds tenfold capacity while remaining scalable. “We had to really plan for the future and really give ourselves the capability to grow,” said Dirk Brand, Head of Engineering at Döhler South Africa. “Not only for the next three years, but for the next ten years.”

Integration for a project of this size and complexity has the potential to become a game of compromise, but with the help of INTEG System Integrators, Döhler South Africa successfully implemented a massive manufacturing system built in Ignition — the unlimited industrial automation platform for SCADA, MES, IIoT, and more — that balances a staggering amount of functionality with an intuitive interface.

Greenfield Development

While the sheer scale of this greenfield project might make some blanch, INTEG viewed this as an opportunity to build from a clean slate. “We could start from the beginning and develop the project like we wanted to, in essence,” said Brian Cooper, Managing Director at INTEG. “On a brownfield project, it's difficult to do that. You've got existing standards, you've got existing equipment, and it makes it difficult.”

While the project requirements remained fairly consistent throughout, on a more granular level there were, inevitably, changes every day. “How we thought it was going to work versus how it actually worked at the end were two very different processes,” said Brand.

“During commissioning, it became apparent how easy it is to make changes on the fly and build new functionality within the SCADA system very quickly,” said Tean Butler, Technical Manager at INTEG.

Now complete, the Ignition system — built from the core combination of Ignition’s Perspective, Tag Historian, and Reporting modules along with Sepasoft’s Batch Procedure Module and the Canary Historian — boasts approximately 1.2 million tags on two gateways, as well as sophisticated batching, navigation, interlocking, and ID generation systems.

Architecture

INTEG originally considered a standard Ignition architecture on a single gateway. However, it quickly became evident that the system — which encompasses around 200 routes, 2,000 phases, and 400 equipment modules for 1,800 control modules — required some additional architectural complexity.

The system features a load-sharing, bifold structure to match the plant’s two sections, each with their own separate gateway, tag provider, and Siemens S7-1500 1518 PLC. The first gateway acts as a hub, running Perspective and housing over 600,000 tags, while the second, a “headless” spoke gateway, has over 500,000 tags. Even with Ignition's unlimited licensing model, a tag count this high requires certain considerations. All of those tags are document text exposed within the User-Defined Type (UDT) structures to allow easy access and increased flexibility with the Siemens PLCs.

ISA 88-Compliant MES

Batching integrates everything in the plant. Using Sepasoft’s Batch Procedure Module as the engine, INTEG developed the MES solution to the exacting standards of the food and beverage industry. “We were quite adamant on using a strict ISA 88 standard,” said Brand.

With an ISA 88-compliant project of this size, it was vital to build the plant according to a set standard, which led INTEG to develop an ID generation system. “The ID generation system was built using Ignition and a database system that helped us to always provide a unique code or unique identifier to each and every single component,” said Butler.

The ID generation system works based on an ownership model to ensure proper interlocking throughout the plant, from general capabilities down to phases, then equipment, and finally to control modules. Because every component in the system has a discrete ID, when an operator runs a batch, the system makes all associated equipment unavailable for any other processes.

Döhler’s plant does not function conventionally via SAP recipes; operators have the flexibility to run batches when needed. Each order comprises several batches as it progresses through the plant, the last of which being the transfer to the shipping truck for delivery. “In order to proceed from one station to another, a batch has to be completed,” said Butler. “One new batch cannot start before a previous batch has been executed.”

Every batch must pass quality control (QC) before moving onto the next process, and equipment must be Clean-In-Place (CIP) before it can be used again. To prevent any batches from starting without proper QC and CIP, INTEG used Ignition’s host of scripting functionalities to implement a sophisticated interlocking system.

“As part of the batching standard that we've developed, we've also implemented a unit state,” said Cooper. “The unit state determines whether the equipment is dirty or clean or being washed or CIP'd, and that is used to interlock specific systems or specific equipment.” The batching system makes cleaning in place exceptionally easy because Döhler can create a recipe to run against the CIP process. The Batch Procedure Module collects this information, recognizing which recipes are linked, and then displays the correct recipe for the operator. This, along with the interlocking that extends down to the control-module level, provides the operator with full visibility of the entire plant from the batching engine.

“Everything is linkable. Everything is trackable,” said Brand. “It really does make their life easier.”

Navigation

Döhler’s staff needed an intuitive method for navigating a system this large and complex. INTEG developed the interface with the simple conceit that an operator should be able to reach any part of the system in three clicks. To accomplish this, they implemented what they dubbed the “breadcrumb” system. “The breadcrumb is an easy way of taking you exactly to that specific area,” said Cooper. “It's developed in a logical way, so if you just know the plant and you know where you wanna go, the breadcrumb would easily take you there.”

This type of quick navigation lends itself naturally to acknowledging alarms. Integrating the breadcrumb system with Ignition’s Alarm Notification Module, INTEG created an easy way for operators and maintenance staff to pinpoint alarms. From the system homepage, operators can simply click on the notification in the header, then filter down through the sections of the plant, following visual indicators to specific areas and process cells.

Alternatively, if operators already know what they’re looking for, they can use the search function. The system follows ISA 95 naming conventions, so by either entering the control module prefix or copying and pasting parameters, operators can quickly scan through the available equipment.

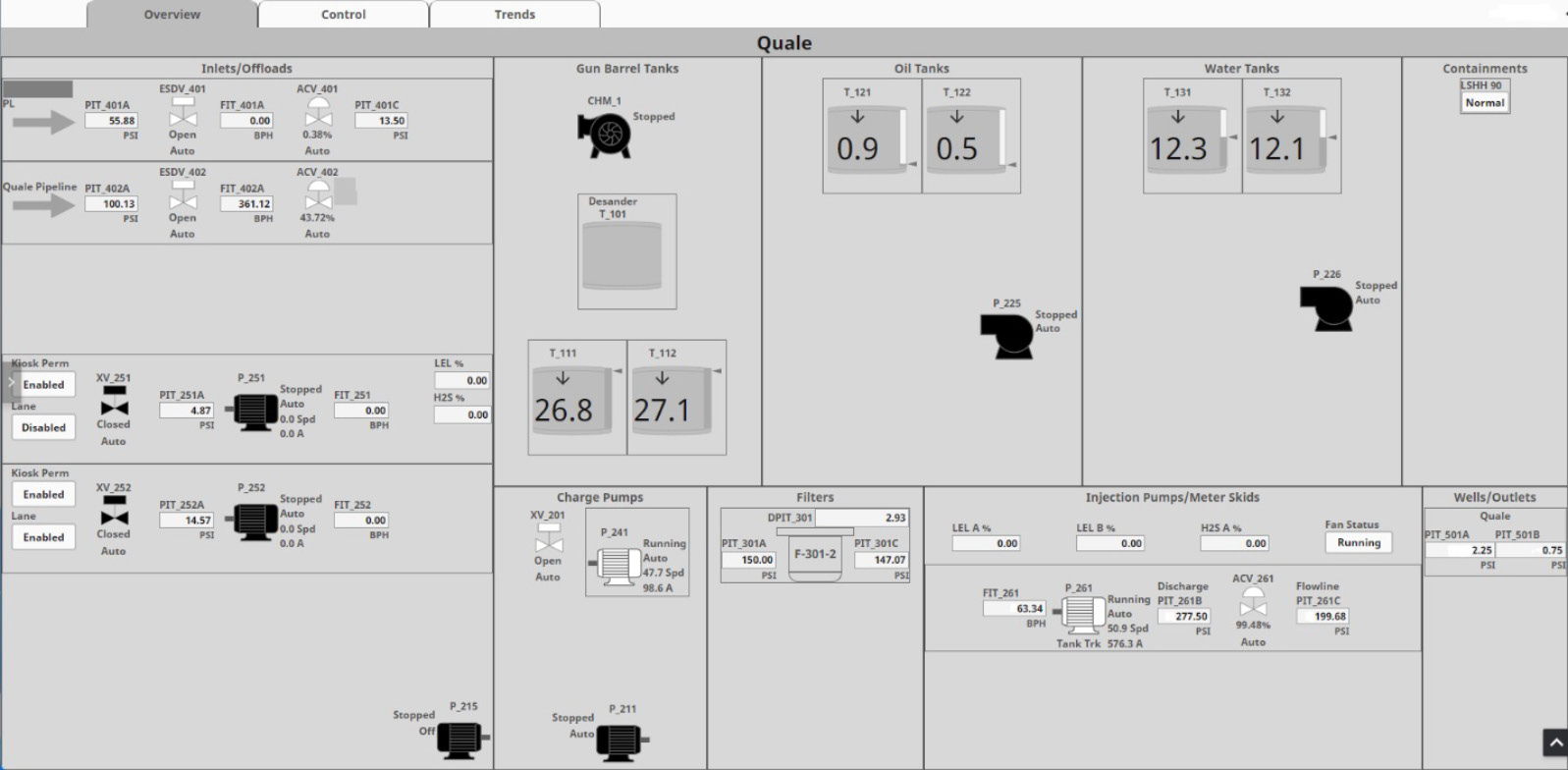

High-Performance HMI

During the commissioning phase, Döhler was unsure whether the plant would have a dedicated control room or field-mounted stations. Ultimately, they opted to forgo a large control room, a decision that greatly influenced the HMI design.

With operators not tied to a central area, INTEG aimed to heighten situational awareness with a high-performance HMI. The grayscale palette reserves color for events or notifications that require immediate attention. “It's easy to build a lot of P&ID pictures and confuse the operators,” said Cooper. “So we developed different layers.” As operators drill down through the layers, they go from overview tiles and simple routes to detailed P&ID-style views, giving individual operators the ability to decide which style works best for them.

“You have buttons and options and menus for everything, but the learning curve was a lot shorter than what I imagined it would be,” said Brand. “Operators pick it up quite quickly.” The Ignition HMI standardizes the look and feel across the whole plant, allowing operators to move from one process to another easily. That flexibility extends to process improvement, letting Döhler add new screens to the Ignition application without restarting or reinstalling the system.

Historical Data And Trending

As with any MES application, historical data and traceability are paramount. Using Ignition, Döhler has complete visibility of their data and the tools to perform root-cause analysis. “It's quite easy now to, within the click of a few buttons, know the exact origin of the problem, the resolution of the problem, and what was done to fix it,” said Brand.

This historical data can also be put to more immediate uses like trending. “We realized that it is necessary for operators to be able to pull up trends easily from the user interface,” said Butler. The system allows operators to access the trending tool from any control module faceplate and easily add values from the same pop-up.

Linguistic Diversity And Symbols

South Africa is host to a huge amount of linguistic diversity, with twelve official languages and at least thirty-five languages spoken in the region. In Paarl and the Western Cape area, there are only three dominant languages, but English — which is used exclusively in Döhler’s Ignition system — would still likely be a second language to much of the company’s staff.

Even without this linguistic hurdle, there is an inherent learning curve for a system with this many moving pieces (not to mention routes for moving those pieces). INTEG sidestepped this potential issue by including symbols throughout the screens to clearly indicate each piece of equipment’s capabilities. “Symbols really helped ease the transition for a lot of the operators,” said Brand. “Something like a mixed proof valve might not be something that's familiar to all the operators, but a picture of a valve makes it clear.”

Maintaining consistent symbols from screen to screen has made it simple for operators to connect the physical plant floor with the representation on the HMI. “The operators picked up on a complex system very easily,” said Cooper. “They, in a short period of time, were able to operate the plant and get product out the door.”

A Communal Success

The success of Döhler’s new facility was truly a group effort. “What really impressed me about the INTEG project team is their product knowledge. The experience with similar plants and similar processes, how proactive they were in identifying potential problems and solving [them] before it becomes a problem,” said Brand.

Likewise, INTEG appreciated the two-way communication during development. As Cooper said of Döhler, “They are knowledgeable people. They gave us feedback and input on control philosophies, on control narratives, and on the methodologies that we used to develop this batching system.”

In addition to technical assistance from Inductive Automation, the project also received support from Element8, the Authorized Ignition Distributor for Sub-Saharan Africa. Butler said, “Any project such as this will encounter technical difficulties, but they had our back all the way.”

With scalability built into the system, Döhler is already looking toward future improvements. “There's almost no limit to what Ignition can offer a client,” concluded Butler, adding that Ignition “makes it easy for developers to express themselves more deeply within the SCADA systems.”

Project Scope

- Start Date: March 2023

- Deploy Date: Phase 1: December 2023, Phase 2: May 2024

- Tags: 1,200,000+

- Screens: 80

- Clients: 7

- Alarms: 6,400

- Devices used:

- Two Siemens S7-1500 1518 CPU

- 600+ ASi-Valves

- 200+ IO-Link Instruments

- 200+ Profinet Remote IO

- 70+ Flowmeters and Drives

- Architectures used: Hub & Spoke

- Databases used: PostgreSQL for access control, trending tool and materials library. NoSQL for historical data logged.

- Historical data logged: 30,000

When Castle & Key took ownership of the long-idled Old Taylor Distillery in Frankfort, Kentucky, and revitalized it as a modern facility, they opted to leave some of the 140-year-old buildings’ wear as is. The property, which features an honest-to-goodness castle, a sunken garden, and the world’s longest rickhouse, had languished in disrepair. Prior to the sale in 2014, there was even talk of deconstructing the castle itself and selling the limestone bricks. Leaving the patinaed brass and occasional cracked tile is an aesthetic choice, one that nods to the site’s history as the birthplace of bourbon hospitality in the 1890s. But step inside, under the original Old Taylor sign, and it’s clear that Castle & Key is equal parts tradition and innovation.

Castle & Key implemented Ignition — an industrial automation platform for SCADA, HMI, IIoT, and more — with the help of Gray AES to replace an outdated FactoryTalk system. Headquartered in nearby Lexington, Gray AES is a professional services company offering architecture, engineering, and automation solutions across a wide range of industries, including major greenfield or brownfield expansions. “Supporting distilled spirits producers and bourbon distillers, being headquartered in Lexington, Kentucky, is very important for us, not just as a systems integrator, but as a corporate citizen of our home state,” said Taylor Sawyer, Director of Business Development at Gray AES.

The two companies have a long history together; before the Ignition implementation, Gray AES had redone Castle & Key’s control cabinet, running new terminals and updating the PLC programming. After that success, Gray AES was the clear choice to upgrade Castle & Key’s SCADA system. As Elliott Schmitz, Distillery Manager at Castle & Key, put it, “Our goals were aligned from the get-go.”

Improving Operational Efficiency

The biggest issue with the old system was the lack of historical data. While Castle & Key could see current production numbers, there was little context. For a company with multiple products that require years to properly mature, this inability to look back made looking forward increasingly difficult. “Distilleries are in a unique position. They have to make decisions on a five-to-ten-year spectrum. They can't make a product today and sell it tomorrow,” said Sawyer.

There is a limit to throughput as well; spirits like bourbon require physical space to age. To remain competitive in the market, Castle & Key needed to use the space they already had to its full potential.

Speaking about operational efficiency, Sawyer said, “It's not so much a buzzword or a euphemism within the industry. It's just the nature of where the industry is heading. How do you do what you're doing today, albeit more efficiently?” This is especially true for a registered historic site that doubles as a production floor.

“We are a historic distillery, but the things we like to modernize aren't necessarily traditional whiskey practices. It’s more [about] improved automation techniques, better data and analytics, correlation and connectivity, and then just constantly being neurotic about scientific advancement of our craft,” said Castle and Key’s Brett Connors, whose formal job title is Whiskey Wizard, a position that encompasses the duties of head blender, product strategy, hospitality, and sales support.

High-Performance HMI

This implementation was Gray AES’ first large-scale project using Ignition’s mobile-responsive Perspective Module. “The main request was to make it a more modern look and feel. Perspective was a natural fit, taking advantage of the CSS and the style sheets,” said Jeremy Plunkett, Digital Transformation Engineer at Gray AES.

Gray AES designed a new SCADA system featuring a high-performance HMI, leveraging modern frameworks closer to website design than traditional SCADA visualization. The goal was to modernize the system to run mostly on iPads while maintaining a close visual resemblance so that operators could easily transition to Ignition with minimal training.

When developing the system, Gray AES utilized DevOps principles. “We would pull down a stack into our local environment, spin it up with Docker, have code reviews using GitHub, and we'd create pull requests for any changes. Then we deploy it to our test server, test out changes before we'd actually deploy it to the production environment,” said Plunkett.

The design process was collaborative between both companies, not just between Gray AES and Castle & Key upper management, but with plant-floor staff as well. One request from operators was to keep the application’s primary color the same. While the new HMI still adheres to the fundamentals of high-performance screens — heavy use of gray, bright colors like red reserved for alarms, minimal clutter — the background is a bright, inviting teal. When activated, all valves, pumps, and motors turn white, in line with the high-performance standard. “It felt very unfamiliar until we had the teal background. And it makes the white stand out a little bit more too,” said Schmitz.

More than anything, this gave operators a sense of ownership of the Ignition system. “At the beginning, operators were a little resistant, just because change is difficult,” said Schmitz. “However, there have been some really good features in Ignition. It’s very easy to navigate and it's been well-received among the team.”

Being able to access the Ignition system through mobile devices has greatly improved operator workflows, and the application’s “crisp” response provides immediate feedback.

UI/UX

The Ignition system defaults to an overview of Castle & Key’s still, giving operators an immediate view of the high-priority functions. The system is logically connected for the process flow, allowing operators to navigate between screens without having to return to the main overview like they did in the previous system.

The side menu provides quick access to other screens within the application. The operator can select the screen, monitor key metrics like temperature, and control distillation to hit target proofs and ensure consistency. With so much information on the screens, operators can move pop-ups out of the way, monitoring flow rate while adjusting the aperture of a valve. Additionally, Gray AES designed a variety of standard faceplates so that anytime Castle & Key needs to add another pump, agitator, or valve, they can reuse assets.

For processes like grain intake, the application shows the operator the entire path flow, including all conveyors and valves, as well as any information required to bring the grain from the truck to one of the silos. In addition to individual mobility, the Ignition system saves time by giving operators access to every part of the facility at any time. For example, when one operator is getting ready to unload a grain truck and does not have an iPad, they can radio for assistance, and another operator can help remotely.

Historian

Beyond the visuals, the Ignition system includes the Tag Historian Module. This allows Castle & Key to easily view historical data, identify trends, and make projections. Perhaps most importantly, this access to historical data allows them to identify anomalies, which can have far-reaching consequences for a process that is still as much art as science.

“On the product strategy and research side, we love the historian functionality of [Ignition] because it allows us to really integrate our product quality to historical records and data to be able to improve our overall strategy and processes,” said Connors. “We're excited about the data being able to come from the historian and to correlate that into our production methodology.”

Alarming

The system also features Ignition’s Alarm Notification Module, which provides two locations where operators can access alarms: current overview and alarm history. The former allows operators to see any active alarms in the system, while the latter gives Castle & Key long-term data, similar to the historian, to make continual improvements and better dial in preventative maintenance.

Prior to Ignition, acknowledging alarms was a highly manual endeavor, requiring an operator to physically walk to a machine (sometimes on a separate level of the production floor) and press a button to stop the process. Now, with Perspective’s mobile-responsive capabilities, operators have a convenient, and immediate, method for responding to alarms.

Momentary Push Buttons

Distillation involves a great deal of sensory response during production; operators monitor the smell, taste, and visual clarity of product as it travels through the system. Fittingly, part of the process is dependent on another sense — touch — more specifically, the need to hold down buttons. “The FactoryTalk application had a lot of momentary push buttons, and that was a bit tricky with Perspective because there's not a one-to-one component that mimics a momentary push button,” said Plunkett. “We didn't want to have to rewrite all the logic in the PLC, so we pretty much created our own custom momentary push button.”

Gray AES’ solution was to let operators tap a button in the Ignition application to “bump” open a valve or open it completely instead of holding down and releasing. Accurate grain weight is a critical component of spirit production, so the ability to slightly open, throttle, and completely close a gate with a tap or two instead of continually holding the button down has been just as, if not more, effective.

Parallel Deployment

As with most manufacturers, Castle & Key could not afford to halt production while Gray AES installed the new system. “We took a gateway backup and dropped it into their Ignition gateway on site. We had a simulation PLC as well, so we had already had all the tags mapped,” said Plunkett.

That last point was originally considered an issue because all labels were stored in the FactoryTalk HMI and could not be directly collected from the PLC. While this task seemed daunting at first, Ignition’s scripting capability allowed Gray AES to write a script that parsed through all of the tags from the HMI, then populated them in Ignition, avoiding what would have been an arduous conversion process.

Deploying the Ignition system was fast (“It took five minutes to deploy,” said Plunkett) but to ensure there was absolutely no downtime, Castle & Key ran the old and new systems in parallel. That way, if there were any unexpected changes after the fact, the plant floor could continue moving, not to mention bubbling, agitating, and distilling. “You can connect either to the control panel on the iPad on the same internal network or be connected to the PLC and Ignition at the same time,” said Schmitz.

“The ability to continuously run on our daily basis as we're developing this new programming system was really paramount because it caused us to not have to lose any production time as we were planning and eventually now transferred onto the new system,” said Connors.

Process Refinement

Shift after shift, Castle & Key is collecting data to further refine their processes. They have found that the Ignition system opens up a whole new path forward. As Schmitz put it, Ignition allows them “to get that access to identify trends and make improvements either to our programming or to mechanical aspects in order to drive consistency.”

Even as Castle & Key plans to expand the system by incorporating more processes, they intend to retain the human element that makes their operation unique. “Our industry relies a lot on organoleptic and sensory data. How do you correlate a human experience to your automated experience?” asked Connors. “To be able to actually take that data and scientific overlay and then apply that to your organoleptic program is incredibly uncommon. That's kind of the way our industry merges the balance of science and art, where we're still very human, but the more we move towards automation, we're not trying to remove that human element from the actual tasting and enjoying of whiskey, but we're trying to imbue that into our scientific ideology.”

Sawyer echoed the sentiment succinctly. “Technology is seen as it's going to replace human beings,” he said. “Here it augments, it enhances.”

Project Scope

- 27,505 Tags

- 27 Screens

- 16 Pop-ups

- 10 Clients

- 736 Alarms

- 1 Devices

- Basic Architecture

- 1 Database

- 62 Tags logging historical data

Driving Efficiency and Visibility at rPlanet Earth

rPlanet Earth partnered with Kanoa to implement Kanoa MES — a modular, composable manufacturing execution system built specifically for Inductive Automation’s Ignition platform.

7 min read

Next to the robotic arms, the off-the-shelf miniature smart homes may not appear to be a key part of Clovis Community College’s Automation, Robotics & Mechatronics lab, but this unassuming hardware is providing students and instructors alike with a unique opportunity to build industry-grade automation applications.

Located in Fresno, California, Clovis Community College is well-regarded for its high transfer rate to four-year institutions. Now, by incorporating Ignition into its curriculum, Clovis is giving students in its Automation, Robotics & Mechatronics program the tools to develop a multifaceted skillset suited to both future higher-learning endeavors and local industry.

Project Development

Matthew Graff, Instructor of Automation, Robotics & Mechatronics at Clovis, was approached by a colleague from Texas A&M University about a grant from the National Science Foundation (NSF) to train high school and college students, as well as instructors, about technology related to the Fourth Industrial Revolution. And, unlike programs that are only able to offer exposure to these concepts, this NSF funding would allow Graff to pay his student researchers.

Graff developed what has been dubbed the “Industry 4.0 Project.” The idea was simple: combine Inductive Automation’s Ignition software — an industrial automation platform for SCADA, HMI, IIoT, and more — with accessible hardware so that students could see immediate real-world results and be inspired to pursue careers in automation.

While developing this curriculum, Graff took inspiration from Walker Reynolds' idea of creating a Unified Namespace (UNS) using a Raspberry Pi. “The idea of using really cheap hardware, Raspberry Pi and Arduinos, to run industrial software made a lot of sense for us in the project,” said Graff. “We wanted something that would be very much hands-on.”

There was just one problem — Graff had no background in working with Raspberry Pis, so he reached out to Bill Kerney, Computer Science Instructor at Clovis. While Kerney describes himself as “not an Ignition user,” his expertise with Linux provided a complementary skillset. “My role here was as an advisor,” he said. “I was here to supervise the student workers on the project, and so when they got stuck figuring out how to do something, then it was my job to unstick them.”

Educational Engagement Program

While Graff had an easy time acquiring the hardware for the project, budgetary constraints prevented him from purchasing full Ignition licenses. Originally, the labs used Ignition in free trial mode, resetting the license every two hours.

When Graff, who has had frustrating experiences with other software companies, learned about Inductive Automation’s Educational Engagement Program (EEP), he sent an email without expecting much, but was surprised to receive a prompt response. “I just got on the website and said, ‘Hey, I'm interested,’ and within a week, we were talking, person to person,” Graff said. Beyond the licenses, the EEP connected him with experts at Inductive Automation to ensure the Industry 4.0 Project met industry standards.

Graff felt his experience was based on a shared ethos. “There's an understanding from Inductive Automation that there's a need to train employees, and they see us as partners,” he said.

Industry 4.0 Project

In the Industry 4.0 Project, students develop an Ignition system that controls a miniature Keyestudio IoT smart home through a combination of a Raspberry Pi and ESP32 Arduinos. Students first set up an MQTT broker using Cirrus Link’s MQTT Transmission Module, which they connect to their edge devices, meaning the smart homes. Next, students establish a UNS, following the ISA-95 standard, to connect to the MQTT broker. Once all the edge devices are publishing to the specific topics, students use the MQTT Engine Module to subscribe to those topics and bring the data into Ignition, creating tags. With these tags, students can build Perspective views and dashboards to display the real-time data.

The system is built in Perspective, meaning that when Graff gives demonstrations for high school students, he can have the class scan a QR code to gain immediate access to the application through their phones, upending the typical “no phones in class” rule. As Graff sees it, “I think a lot of times, there's the difficulty of how we make technology used for a positive thing.”

And with the combination of Ignition and smart homes, the positive results arrive quickly. “They can open up the box and hopefully within a class period, 45 minutes or an hour, have something working. They're pushing buttons and seeing responses. And so in that, immediately, they're learning some basic things like setup, using the Unified Namespace,” said Graff.

The collegiate counterparts replace the Raspberry Pi with more professional hardware, courtesy of Opto 22. The combination of Ignition and Opto 22’s groov RIO has been inspiring to the Clovis students. “Computer science majors oftentimes will live in this sort of platonic world of ideals and algorithms that are very abstract,” said Kerney. “Getting them to actually turn a motor on or to turn a light on or to open a door is oftentimes just a mind-blowing experience for them.”

Julian Laxamana, a student researcher working on the Industry 4.0 Project, found the ability to bring his programming into a tangible realm extremely gratifying. “It's really easy to have all your data in one place, which is really nuanced because if you make it by scratch, you have to have each computer send data, and you have to get it to show up on some GUI, which is really hard to get set up. But Ignition makes that a lot easier to link up all the data from the sensors to the computer,” said Laxamana.

Laxamana, who had no previous Ignition experience, also integrated the Ignition system with a camera that analyzes its video feed in (almost) real time. “We currently use YOLOv8 to collect data from ESP32 cameras, process it through the Raspberry Pi, and then display it on a web page, which Ignition gets the data from.”

Graff, who has strived to make the Industry 4.0 Project a “student-centered teaching system,” was ecstatic to see his student taking initiative with Ignition, saying, “I just showed Julian a few things. And then the next thing I know, he's brought a video in with object detection that's run on another application.”

Kerney agrees that it’s exciting to see Ignition acting as a catalyst for students. “Most computer science majors, if you told them, ‘Make a smart house that the door opens and closes,’ and has all these sensors, they won't even know where to begin, but with Ignition in it they were able to get this whole system up and running in a pretty fast amount of time.”

Transition To Industry

Entering its second year, the Industry 4.0 Project has already led to real-world success for students.

Gurkaran Singh, a student worker at Clovis studying industrial automation, was one of the main driving forces behind the Industry 4.0 Project, but most of his experience came from working on the project itself. “Before I came to Clovis, I had limited experience in industrial automation. I had only done one PLC programming class, and I had never heard about MQTT or SCADA or Ignition,” said Singh.

Even without prior Ignition experience, between free resources like Inductive University and the Ignition user manual, Singh quickly discovered the breadth of functionality he could develop in the platform. “One thing I really liked about Ignition early on was how easy it was to download and set up on my own personal computer, to begin learning,” he said.

To gain a better understanding of the groov product line, Graff and Singh traveled to Opto 22’s headquarters in Temecula for a four-day training course. During the training, Singh learned about Farm Data Systems (FDS), an integrator specializing in agricultural automation and monitoring, utilizing a combination of Ignition and Opto 22 hardware. FDS uses its Water Informatics product to monitor and control irrigation for thousands of sites. “With Ignition, we've been able to really turn the corner for our customers in terms of giving them many systems and features that they've never had access to before. It's been quite revolutionary for our growers,” said John Williamson, President of FDS.

What piqued Singh’s interest was that FDS’ office was located in Madera, about a 40-minute drive from Clovis’ campus. With guidance from Graff, Singh emailed Williamson, expressing his interest in a job and citing his experience working with Ignition and Opto 22 products in the Industry 4.0 Project. Williamson was impressed and offered Singh a position, saying, “His career objectives were very much in line with what we were doing. So we met in person, and I already knew he could add value on day one. His training at college was really so well suited to the work we're doing here.”

Even in his first few months of employment, Singh is already helping Williamson to design Ignition interfaces based on customer requirements, configure PLCs, and build panels for field deployment in addition to daily concerns like alerts from customer sites. “My day to day over at Farm Data Systems includes configuring Opto 22 products for upcoming projects, monitoring alarms for the products that are already out in the field, trying to troubleshoot any networking issues that we face, and trying to help customers solve those problems,” said Singh.

“It's been really a remarkable experience for us to work with Ignition,” said Williamson. “The product that we bring to the market is just leaps and bounds ahead of anything anybody else can provide to help farmers do their job.”

Real-World Skills

The Industry 4.0 Project helps students build a foundation based on technical experience and critical thinking skills that are so vital in industry. Troubleshooting, in particular, can be the crux of any real-world system. “What we realized with this project is automatically just connecting a bunch of things using standard industrial protocols for Ethernet, there's a bunch of troubleshooting that has to happen even if everything's working,” said Graff.

The combination of software and hardware gives students the space to learn what to do when a system doesn’t work, which can be more valuable long term. “Using hardware, you have the opportunity to make more mistakes. It may be a wiring issue or it could be a software issue such as setting an incorrect IP address. It helps you gain a deeper understanding of the whole system,” said Singh.

Additionally, the project puts many of the automation and computer science concepts taught at Clovis into the context of a complete system. “While working in industrial automation, at some point, you're gonna come across a problem where you need to integrate different devices, using different communication protocols,” said Singh. “Ignition is a really useful tool, in bringing all those different devices from different protocols together and utilizing that data to store, analyze, and generate some useful insights, and even building HMI displays for control.”

“I see Ignition as being a Rosetta Stone, and that's how I describe it to students where it can translate and connect all kinds of components together in a factory,” said Graff.

Sharing This Knowledge

Over the past year, the Industry 4.0 Project has expanded to five other colleges and 10 high schools, with plans to include five additional colleges and seven more high schools in the coming year. For Graff, sharing the project with other schools is about reaching the next generation of engineers. “A lot of high school students don't realize there's jobs related to industrial automation, and they could go into the engineering or computer science pathway,” he said.

“We've had three software engineers working on this project. The first one, Neiro Cabrera, worked on this for about a year and then he transferred to UCLA and then he just recently messaged me and told me that he got a job in a related industry,” said Kerney. “An absolute success story. He worked on this. He got experience in it. He found he loved it.”

This sense of discovery is a sentiment that Singh echoes. “When I first joined the industrial automation program here at Clovis Community College, my career goal was to be on the plant floor,” he said. “Working with this project has exposed me to newer and emerging technologies and broadened my horizon and opened me to a lot more opportunities within the field.”

Clovis does not want to gatekeep this knowledge or technology. In an effort to increase the accessibility of the project, Graff and Kerney set up a Github page that details the hardware and software requirements for the project, along with instructions for configuring components as well as lab exercises and training materials. “We want to share everything we have here,” said Graff. “You can take this and use it in a classroom. Or if you're just someone that wants to have a fun automation project, maybe before you hook up your whole home to be a smart home, you can just get a little $55 home from Amazon and pay $100 for a Raspberry Pi, and you'll be set to go.”

Learn more about Inductive Automation's educational initiatives in the blog post "IA’s Efforts To Shape The Future Of Industrial Automation."

Transcript:

0:00:11.5

Matthew Graff: I'm Matthew Graff. I work here at Clovis Community College. I'm an Instructor of Automation, Robotics, Mechatronics. What we do here in the lab is teach students on industrial automation. So a few years ago, I got contacted from a professor at Texas A&M if I wanted to be involved in a National Science Foundation project. And the project was focusing on training technicians in the Fourth Industrial Revolution. So when the grant was awarded, I let my computer science colleague know that there was a position that he could work on this grant with me. The reason I brought the computer science department in is I had no background in working with something like a Raspberry Pi and so I needed that expertise. We brought in multiple student workers over time and they assisted in getting Ignition on the Raspberry Pi, getting the system working, stuff that a computer science student could do pretty easily, but it was just not the background that myself or students in industrial automation program normally have.

0:01:16.3

Bill Kerney: My name is Bill Kerney. I am an Instructor of Computer Science here at Clovis Community College. I've been working on this project for about two years now. My role here was as an advisor. I was here to supervise the student workers on the project. And so, when they got stuck figuring out how to do something, then it was my job to unstick them.

0:01:35.1

Matthew Graff: We are training high school teachers and college instructors on the Fourth Industrial Revolution system or Industry 4.0 Project. And so what we do is we show the students how to initialize the system and then do some troubleshooting. I've been very impressed working with the Educational Engagement Program with Inductive Automation. Just from the get go, I just got on the website and said, "Hey, I'm interested." And within a week, we were talking person to person going, "Hey, this is what we're trying to do, what we need to accomplish." From there they were able to connect us with others in Inductive Automation to help with the project and give some feedback so that we would be doing stuff to industrial standards.

0:02:17.9

Julian Laxamana: My name is Julian Laxamana. I'm currently a Student Researcher here at Clovis Community College working on the Industry 4.0 Project. I work with the Raspberry Pis and Arduinos to collect data from smart homes and display it on the Ignition webpage.

0:02:31.7

Gurkaran Singh: My name is Gurkaran Singh. I'm a student here at Clovis Community College studying industrial automation. I'm also a student employee. My main focus with the project is to establish MQTT connections between the edge devices and the Ignition SCADA.

0:02:51.1

Matthew Graff: We're focusing a lot on using what Walker Reynolds called a Unified Namespace. And we're using MQTT to move the data around. As we build out the system, we wanted something that literally for around $200 of hardware, someone could learn and experience how to use Ignition. It goes down to just a really simple smart home that they're programming and setting up and configuring a Namespace for. The visualization is a big part. And so, we're using Perspective. One fun story was I was at a high school and I could see the teacher walking around telling students, they're secretly pulling their cell phones out and telling them put away. I turned around and said, "Hey, here's the address. Connect to this and you can connect into the system." And so then they had Perspective running on their phone.

0:03:45.7

Julian Laxamana: We're having the Raspberry Pi run Ignition on a terminal. And then the Arduinos connect the MQTT broker through Namespace and it sends the data through there. And you can connect through your phone or laptop and see the data from the Arduinos, which is really cool. This is the Ignition webpage to control the smart home for this smart home here. So you can set the LED color like here, and then set the yellow LED here, and there's a little door on it.

0:04:19.3

Gurkaran Singh: Basically, we're using Ignition as a MQTT broker, using the MQTT Distributor Module as the broker. And then, we're connecting all the edge devices, which are our smart homes, to the broker, and that's how we're getting the data into Ignition. Once we've got the tags in Ignition, I go ahead and create the UDTs and once they're on, I build the Perspective views. Once we've got the edge devices configured and publishing to the broker, we should be able to see the data come in on the MQTT Engine [Module] on Ignition. So the Namespace that we are using follows a simple structure. We've got a generic name "Smart Company" and then a neighborhood. So for each new neighborhood, we'll increment the number. And for each neighborhood, we've got object detection. You've got smart farms, and then we got smart homes. Under each smart home are all the homes that are currently connected and publishing data. And these are all the tags that are being published. These tags are being used on here on this Perspective view displaying the data such as count, humidity, temperature, and there is some data coming in. The push buttons got motion and there's a touch. We could switch the homes from the smart home number.

0:05:36.0

Gurkaran Singh: This dropdown auto-updates each time a new home disconnects or connects. For troubleshooting the MQTT communications, I use MQTT Explorer connecting to the broker. It's really easy to see all the data come in and confirm that the homes that are actually connected we are able to receive that data on the broker.

0:05:58.8

Matthew Graff: We also didn't want people to have the view that this is just like using cheap off-the-shelf toys and it has nothing related to industrial products. So what we did is we looked out and tried to find a product that would be similar that's being used in industry. We located Opto 22. They have a single board Linux system and we've used that for our college level systems. So we are giving institutions, through our grant, those Opto 22s and they're able to experience both working with cheap system that they could easily buy for a whole classroom, every student, and using industrial system with Opto 22. Having student workers has been helpful because I could see how much they could take on and also discuss with them well, how would we teach other students? Bouncing ideas off of them and trying to create a student-centered approach to teaching. Julian brought a video in from object detection that's run on another application.

0:07:01.1

Julian Laxamana: We currently use YOLOv8 to collect data from ESP32 cameras and then process it through the Raspberry Pi and then that displays it on a webpage, which Ignition gets the data from and displays it on there.

0:07:17.0

Matthew Graff: Working on this project has really exceeded my expectations. Been super impressed with students working at different levels. They generally have brought the project further along than I was able to do just on my own.

0:07:31.2

Gurkaran Singh: Working on this project exposed me to Ignition and Opto 22 and MQTT. I found this local company focused on agricultural monitoring and automation. Their main product was based on Ignition. They were using Opto 22s for their controls and MQTT to transmit all the data. I reached out and expressed my interest and next morning I hear back from the president of the company and my skills aligned with their products, which led me to be able to get a job over there.

0:08:04.1

John Williamson: My name is John Williamson. I am the President of Farm Data Systems. We have about 20 years experience working with farmers to help them improve irrigation management. We've been working with Opto for about eight years now, using their controllers for Ignition. We've been working with them for about six years now, so we've probably done a couple hundred projects already with Ignition. So one of our biggest challenges is building a team of technicians who have capabilities around Ignition and low-voltage electrical systems. But one day Gurkaran contacted us directly, which was really good. We had internships available at the time, but Gurkaran expressed an interest in a full-time position. So I talked to him over the phone and it was very clear his career objectives were very much in line with what we were doing. So we met in-person and I already knew he could add value on day one. His training at college was really so well suited to the work we're doing here. Can't speak highly enough about the program and how well suited it is to our business.

0:09:05.9

Gurkaran Singh: My day to day over at Farm Data System includes configuring Opto 22 products for upcoming projects, monitoring alarms for the products that are already out in the field, trying to troubleshoot any networking issues that we face, and trying to help customers solve those problems. I feel that the skills that I learned working with the Industry 4.0 Project were highly relevant and were really beneficial for me in being able to be successful in my current role.

0:09:38.0

Bill Kerney: We've had software engineers work on this project. The first one, Neiro Cabrera, worked on this for about a year and then he transferred to UCLA and then he just recently messaged me and told me that he got a job in a related industry. So an absolute success story.

0:09:51.5

Julian Laxamana: Working with Ignition and all the software we have now provides a good foundation for me to build other projects in the future.

0:09:58.7

Gurkaran Singh: Learning all these concepts, using hardware as well as software, helped me improve my troubleshooting skills. While using hardware, you have opportunity to make more mistakes. It may be a wiring issue or it could be a software issue such as setting an incorrect IP address. It helps you gain a deeper understanding of the whole system, trying to troubleshoot the issues and fixing the problem.

0:10:24.1

Matthew Graff: Projects really get students excited and so when we use Ignition, we see students, rather than trying to race to the door and leave five minutes early, they stay around for maybe an hour or two extra trying to get their project working.

0:10:42.2

Bill Kerney: One of the things I work on with my students a lot is trying to get them to go out into the real world and interface with the real world. Getting them to actually turn a motor on or to turn a light on or to open a door and things like that is oftentimes just a mind-blowing experience for them.

0:10:56.2

Julian Laxamana: Very cool for students to see their knowledge have a physical effect on the real world.

0:11:01.0

Matthew Graff: I encourage anyone who wants to look at this project go to our GitHub page. This was funded by the National Science Foundation and I just feel like we are obligated and we want to share everything we have here. There's nothing we're hiding, so feel free to use that. You can take this and use it in a classroom, or if you're an engineer and you just wanna poke around, or just someone that wants to have a fun automation project, you can just get a little $55 home from Amazon and pay a $100 for for a Raspberry Pi and you'll be set to go.

Building Sustainable Industrial Systems And A Better Future

Join control system experts as they share real-world Ignition projects that are helping organizations in various industries make significant progress in their sustainability goals, from reducing paper usage, to effective energy monitoring, lowering carbon footprints, providing cleaner energy, and more.

57 min video

Level Up Your Knowledge At The 2025 Ignition Community Conference

If you’re thinking about coming to ICC but haven’t quite made up your mind, or if you’re planning to come for the first time and wondering what to expect, get a sneak peek by watching this free webinar. You’ll learn why ICC 2025 on September 16–18, 2025 in Sacramento, CA is a can’t-miss event and a great investment in your future success!

65 min video

In 2022, Döhler South Africa realized they were reaching capacity in their production facility, an impasse that countless growing companies have reached. The question always becomes: make do with too-cramped quarters or invest in a long-term solution?

Döhler — a multinational company that manufactures fruit juices, compounds, flavors, emulsions, and concentrates — chose the latter for their new facility, which specializes in blending and secondary transformation. Located in Paarl, South Africa, the new plant adds tenfold capacity while remaining scalable. “We had to really plan for the future and really give ourselves the capability to grow,” said Dirk Brand, Head of Engineering at Döhler South Africa. “Not only for the next three years, but for the next ten years.”

Integration for a project of this size and complexity has the potential to become a game of compromise, but with the help of INTEG System Integrators, Döhler South Africa successfully implemented a massive manufacturing system built in Ignition — the unlimited industrial automation platform for SCADA, MES, IIoT, and more — that balances a staggering amount of functionality with an intuitive interface.

Greenfield Development

While the sheer scale of this greenfield project might make some blanch, INTEG viewed this as an opportunity to build from a clean slate. “We could start from the beginning and develop the project like we wanted to, in essence,” said Brian Cooper, Managing Director at INTEG. “On a brownfield project, it's difficult to do that. You've got existing standards, you've got existing equipment, and it makes it difficult.”

While the project requirements remained fairly consistent throughout, on a more granular level there were, inevitably, changes every day. “How we thought it was going to work versus how it actually worked at the end were two very different processes,” said Brand.

“During commissioning, it became apparent how easy it is to make changes on the fly and build new functionality within the SCADA system very quickly,” said Tean Butler, Technical Manager at INTEG.

Now complete, the Ignition system — built from the core combination of Ignition’s Perspective, Tag Historian, and Reporting modules along with Sepasoft’s Batch Procedure Module and the Canary Historian — boasts approximately 1.2 million tags on two gateways, as well as sophisticated batching, navigation, interlocking, and ID generation systems.

Architecture

INTEG originally considered a standard Ignition architecture on a single gateway. However, it quickly became evident that the system — which encompasses around 200 routes, 2,000 phases, and 400 equipment modules for 1,800 control modules — required some additional architectural complexity.

The system features a load-sharing, bifold structure to match the plant’s two sections, each with their own separate gateway, tag provider, and Siemens S7-1500 1518 PLC. The first gateway acts as a hub, running Perspective and housing over 600,000 tags, while the second, a “headless” spoke gateway, has over 500,000 tags. Even with Ignition's unlimited licensing model, a tag count this high requires certain considerations. All of those tags are document text exposed within the User-Defined Type (UDT) structures to allow easy access and increased flexibility with the Siemens PLCs.

ISA 88-Compliant MES

Batching integrates everything in the plant. Using Sepasoft’s Batch Procedure Module as the engine, INTEG developed the MES solution to the exacting standards of the food and beverage industry. “We were quite adamant on using a strict ISA 88 standard,” said Brand.

With an ISA 88-compliant project of this size, it was vital to build the plant according to a set standard, which led INTEG to develop an ID generation system. “The ID generation system was built using Ignition and a database system that helped us to always provide a unique code or unique identifier to each and every single component,” said Butler.

The ID generation system works based on an ownership model to ensure proper interlocking throughout the plant, from general capabilities down to phases, then equipment, and finally to control modules. Because every component in the system has a discrete ID, when an operator runs a batch, the system makes all associated equipment unavailable for any other processes.

Döhler’s plant does not function conventionally via SAP recipes; operators have the flexibility to run batches when needed. Each order comprises several batches as it progresses through the plant, the last of which being the transfer to the shipping truck for delivery. “In order to proceed from one station to another, a batch has to be completed,” said Butler. “One new batch cannot start before a previous batch has been executed.”

Every batch must pass quality control (QC) before moving onto the next process, and equipment must be Clean-In-Place (CIP) before it can be used again. To prevent any batches from starting without proper QC and CIP, INTEG used Ignition’s host of scripting functionalities to implement a sophisticated interlocking system.

“As part of the batching standard that we've developed, we've also implemented a unit state,” said Cooper. “The unit state determines whether the equipment is dirty or clean or being washed or CIP'd, and that is used to interlock specific systems or specific equipment.” The batching system makes cleaning in place exceptionally easy because Döhler can create a recipe to run against the CIP process. The Batch Procedure Module collects this information, recognizing which recipes are linked, and then displays the correct recipe for the operator. This, along with the interlocking that extends down to the control-module level, provides the operator with full visibility of the entire plant from the batching engine.

“Everything is linkable. Everything is trackable,” said Brand. “It really does make their life easier.”

Navigation

Döhler’s staff needed an intuitive method for navigating a system this large and complex. INTEG developed the interface with the simple conceit that an operator should be able to reach any part of the system in three clicks. To accomplish this, they implemented what they dubbed the “breadcrumb” system. “The breadcrumb is an easy way of taking you exactly to that specific area,” said Cooper. “It's developed in a logical way, so if you just know the plant and you know where you wanna go, the breadcrumb would easily take you there.”

This type of quick navigation lends itself naturally to acknowledging alarms. Integrating the breadcrumb system with Ignition’s Alarm Notification Module, INTEG created an easy way for operators and maintenance staff to pinpoint alarms. From the system homepage, operators can simply click on the notification in the header, then filter down through the sections of the plant, following visual indicators to specific areas and process cells.

Alternatively, if operators already know what they’re looking for, they can use the search function. The system follows ISA 95 naming conventions, so by either entering the control module prefix or copying and pasting parameters, operators can quickly scan through the available equipment.

High-Performance HMI

During the commissioning phase, Döhler was unsure whether the plant would have a dedicated control room or field-mounted stations. Ultimately, they opted to forgo a large control room, a decision that greatly influenced the HMI design.

With operators not tied to a central area, INTEG aimed to heighten situational awareness with a high-performance HMI. The grayscale palette reserves color for events or notifications that require immediate attention. “It's easy to build a lot of P&ID pictures and confuse the operators,” said Cooper. “So we developed different layers.” As operators drill down through the layers, they go from overview tiles and simple routes to detailed P&ID-style views, giving individual operators the ability to decide which style works best for them.

“You have buttons and options and menus for everything, but the learning curve was a lot shorter than what I imagined it would be,” said Brand. “Operators pick it up quite quickly.” The Ignition HMI standardizes the look and feel across the whole plant, allowing operators to move from one process to another easily. That flexibility extends to process improvement, letting Döhler add new screens to the Ignition application without restarting or reinstalling the system.

Historical Data And Trending

As with any MES application, historical data and traceability are paramount. Using Ignition, Döhler has complete visibility of their data and the tools to perform root-cause analysis. “It's quite easy now to, within the click of a few buttons, know the exact origin of the problem, the resolution of the problem, and what was done to fix it,” said Brand.

This historical data can also be put to more immediate uses like trending. “We realized that it is necessary for operators to be able to pull up trends easily from the user interface,” said Butler. The system allows operators to access the trending tool from any control module faceplate and easily add values from the same pop-up.

Linguistic Diversity And Symbols

South Africa is host to a huge amount of linguistic diversity, with twelve official languages and at least thirty-five languages spoken in the region. In Paarl and the Western Cape area, there are only three dominant languages, but English — which is used exclusively in Döhler’s Ignition system — would still likely be a second language to much of the company’s staff.

Even without this linguistic hurdle, there is an inherent learning curve for a system with this many moving pieces (not to mention routes for moving those pieces). INTEG sidestepped this potential issue by including symbols throughout the screens to clearly indicate each piece of equipment’s capabilities. “Symbols really helped ease the transition for a lot of the operators,” said Brand. “Something like a mixed proof valve might not be something that's familiar to all the operators, but a picture of a valve makes it clear.”

Maintaining consistent symbols from screen to screen has made it simple for operators to connect the physical plant floor with the representation on the HMI. “The operators picked up on a complex system very easily,” said Cooper. “They, in a short period of time, were able to operate the plant and get product out the door.”

A Communal Success

The success of Döhler’s new facility was truly a group effort. “What really impressed me about the INTEG project team is their product knowledge. The experience with similar plants and similar processes, how proactive they were in identifying potential problems and solving [them] before it becomes a problem,” said Brand.

Likewise, INTEG appreciated the two-way communication during development. As Cooper said of Döhler, “They are knowledgeable people. They gave us feedback and input on control philosophies, on control narratives, and on the methodologies that we used to develop this batching system.”

In addition to technical assistance from Inductive Automation, the project also received support from Element8, the Authorized Ignition Distributor for Sub-Saharan Africa. Butler said, “Any project such as this will encounter technical difficulties, but they had our back all the way.”

With scalability built into the system, Döhler is already looking toward future improvements. “There's almost no limit to what Ignition can offer a client,” concluded Butler, adding that Ignition “makes it easy for developers to express themselves more deeply within the SCADA systems.”

Project Scope

- Start Date: March 2023

- Deploy Date: Phase 1: December 2023, Phase 2: May 2024

- Tags: 1,200,000+

- Screens: 80

- Clients: 7

- Alarms: 6,400

- Devices used:

- Two Siemens S7-1500 1518 CPU

- 600+ ASi-Valves

- 200+ IO-Link Instruments

- 200+ Profinet Remote IO

- 70+ Flowmeters and Drives

- Architectures used: Hub & Spoke

- Databases used: PostgreSQL for access control, trending tool and materials library. NoSQL for historical data logged.

- Historical data logged: 30,000

Next to the robotic arms, the off-the-shelf miniature smart homes may not appear to be a key part of Clovis Community College’s Automation, Robotics & Mechatronics lab, but this unassuming hardware is providing students and instructors alike with a unique opportunity to build industry-grade automation applications.

Located in Fresno, California, Clovis Community College is well-regarded for its high transfer rate to four-year institutions. Now, by incorporating Ignition into its curriculum, Clovis is giving students in its Automation, Robotics & Mechatronics program the tools to develop a multifaceted skillset suited to both future higher-learning endeavors and local industry.

Project Development

Matthew Graff, Instructor of Automation, Robotics & Mechatronics at Clovis, was approached by a colleague from Texas A&M University about a grant from the National Science Foundation (NSF) to train high school and college students, as well as instructors, about technology related to the Fourth Industrial Revolution. And, unlike programs that are only able to offer exposure to these concepts, this NSF funding would allow Graff to pay his student researchers.

Graff developed what has been dubbed the “Industry 4.0 Project.” The idea was simple: combine Inductive Automation’s Ignition software — an industrial automation platform for SCADA, HMI, IIoT, and more — with accessible hardware so that students could see immediate real-world results and be inspired to pursue careers in automation.

While developing this curriculum, Graff took inspiration from Walker Reynolds' idea of creating a Unified Namespace (UNS) using a Raspberry Pi. “The idea of using really cheap hardware, Raspberry Pi and Arduinos, to run industrial software made a lot of sense for us in the project,” said Graff. “We wanted something that would be very much hands-on.”

There was just one problem — Graff had no background in working with Raspberry Pis, so he reached out to Bill Kerney, Computer Science Instructor at Clovis. While Kerney describes himself as “not an Ignition user,” his expertise with Linux provided a complementary skillset. “My role here was as an advisor,” he said. “I was here to supervise the student workers on the project, and so when they got stuck figuring out how to do something, then it was my job to unstick them.”

Educational Engagement Program

While Graff had an easy time acquiring the hardware for the project, budgetary constraints prevented him from purchasing full Ignition licenses. Originally, the labs used Ignition in free trial mode, resetting the license every two hours.

When Graff, who has had frustrating experiences with other software companies, learned about Inductive Automation’s Educational Engagement Program (EEP), he sent an email without expecting much, but was surprised to receive a prompt response. “I just got on the website and said, ‘Hey, I'm interested,’ and within a week, we were talking, person to person,” Graff said. Beyond the licenses, the EEP connected him with experts at Inductive Automation to ensure the Industry 4.0 Project met industry standards.

Graff felt his experience was based on a shared ethos. “There's an understanding from Inductive Automation that there's a need to train employees, and they see us as partners,” he said.

Industry 4.0 Project

In the Industry 4.0 Project, students develop an Ignition system that controls a miniature Keyestudio IoT smart home through a combination of a Raspberry Pi and ESP32 Arduinos. Students first set up an MQTT broker using Cirrus Link’s MQTT Transmission Module, which they connect to their edge devices, meaning the smart homes. Next, students establish a UNS, following the ISA-95 standard, to connect to the MQTT broker. Once all the edge devices are publishing to the specific topics, students use the MQTT Engine Module to subscribe to those topics and bring the data into Ignition, creating tags. With these tags, students can build Perspective views and dashboards to display the real-time data.

The system is built in Perspective, meaning that when Graff gives demonstrations for high school students, he can have the class scan a QR code to gain immediate access to the application through their phones, upending the typical “no phones in class” rule. As Graff sees it, “I think a lot of times, there's the difficulty of how we make technology used for a positive thing.”

And with the combination of Ignition and smart homes, the positive results arrive quickly. “They can open up the box and hopefully within a class period, 45 minutes or an hour, have something working. They're pushing buttons and seeing responses. And so in that, immediately, they're learning some basic things like setup, using the Unified Namespace,” said Graff.

The collegiate counterparts replace the Raspberry Pi with more professional hardware, courtesy of Opto 22. The combination of Ignition and Opto 22’s groov RIO has been inspiring to the Clovis students. “Computer science majors oftentimes will live in this sort of platonic world of ideals and algorithms that are very abstract,” said Kerney. “Getting them to actually turn a motor on or to turn a light on or to open a door is oftentimes just a mind-blowing experience for them.”

Julian Laxamana, a student researcher working on the Industry 4.0 Project, found the ability to bring his programming into a tangible realm extremely gratifying. “It's really easy to have all your data in one place, which is really nuanced because if you make it by scratch, you have to have each computer send data, and you have to get it to show up on some GUI, which is really hard to get set up. But Ignition makes that a lot easier to link up all the data from the sensors to the computer,” said Laxamana.

Laxamana, who had no previous Ignition experience, also integrated the Ignition system with a camera that analyzes its video feed in (almost) real time. “We currently use YOLOv8 to collect data from ESP32 cameras, process it through the Raspberry Pi, and then display it on a web page, which Ignition gets the data from.”

Graff, who has strived to make the Industry 4.0 Project a “student-centered teaching system,” was ecstatic to see his student taking initiative with Ignition, saying, “I just showed Julian a few things. And then the next thing I know, he's brought a video in with object detection that's run on another application.”

Kerney agrees that it’s exciting to see Ignition acting as a catalyst for students. “Most computer science majors, if you told them, ‘Make a smart house that the door opens and closes,’ and has all these sensors, they won't even know where to begin, but with Ignition in it they were able to get this whole system up and running in a pretty fast amount of time.”

Transition To Industry

Entering its second year, the Industry 4.0 Project has already led to real-world success for students.

Gurkaran Singh, a student worker at Clovis studying industrial automation, was one of the main driving forces behind the Industry 4.0 Project, but most of his experience came from working on the project itself. “Before I came to Clovis, I had limited experience in industrial automation. I had only done one PLC programming class, and I had never heard about MQTT or SCADA or Ignition,” said Singh.

Even without prior Ignition experience, between free resources like Inductive University and the Ignition user manual, Singh quickly discovered the breadth of functionality he could develop in the platform. “One thing I really liked about Ignition early on was how easy it was to download and set up on my own personal computer, to begin learning,” he said.

To gain a better understanding of the groov product line, Graff and Singh traveled to Opto 22’s headquarters in Temecula for a four-day training course. During the training, Singh learned about Farm Data Systems (FDS), an integrator specializing in agricultural automation and monitoring, utilizing a combination of Ignition and Opto 22 hardware. FDS uses its Water Informatics product to monitor and control irrigation for thousands of sites. “With Ignition, we've been able to really turn the corner for our customers in terms of giving them many systems and features that they've never had access to before. It's been quite revolutionary for our growers,” said John Williamson, President of FDS.

What piqued Singh’s interest was that FDS’ office was located in Madera, about a 40-minute drive from Clovis’ campus. With guidance from Graff, Singh emailed Williamson, expressing his interest in a job and citing his experience working with Ignition and Opto 22 products in the Industry 4.0 Project. Williamson was impressed and offered Singh a position, saying, “His career objectives were very much in line with what we were doing. So we met in person, and I already knew he could add value on day one. His training at college was really so well suited to the work we're doing here.”

Even in his first few months of employment, Singh is already helping Williamson to design Ignition interfaces based on customer requirements, configure PLCs, and build panels for field deployment in addition to daily concerns like alerts from customer sites. “My day to day over at Farm Data Systems includes configuring Opto 22 products for upcoming projects, monitoring alarms for the products that are already out in the field, trying to troubleshoot any networking issues that we face, and trying to help customers solve those problems,” said Singh.

“It's been really a remarkable experience for us to work with Ignition,” said Williamson. “The product that we bring to the market is just leaps and bounds ahead of anything anybody else can provide to help farmers do their job.”

Real-World Skills

The Industry 4.0 Project helps students build a foundation based on technical experience and critical thinking skills that are so vital in industry. Troubleshooting, in particular, can be the crux of any real-world system. “What we realized with this project is automatically just connecting a bunch of things using standard industrial protocols for Ethernet, there's a bunch of troubleshooting that has to happen even if everything's working,” said Graff.

The combination of software and hardware gives students the space to learn what to do when a system doesn’t work, which can be more valuable long term. “Using hardware, you have the opportunity to make more mistakes. It may be a wiring issue or it could be a software issue such as setting an incorrect IP address. It helps you gain a deeper understanding of the whole system,” said Singh.

Additionally, the project puts many of the automation and computer science concepts taught at Clovis into the context of a complete system. “While working in industrial automation, at some point, you're gonna come across a problem where you need to integrate different devices, using different communication protocols,” said Singh. “Ignition is a really useful tool, in bringing all those different devices from different protocols together and utilizing that data to store, analyze, and generate some useful insights, and even building HMI displays for control.”

“I see Ignition as being a Rosetta Stone, and that's how I describe it to students where it can translate and connect all kinds of components together in a factory,” said Graff.

Sharing This Knowledge

Over the past year, the Industry 4.0 Project has expanded to five other colleges and 10 high schools, with plans to include five additional colleges and seven more high schools in the coming year. For Graff, sharing the project with other schools is about reaching the next generation of engineers. “A lot of high school students don't realize there's jobs related to industrial automation, and they could go into the engineering or computer science pathway,” he said.

“We've had three software engineers working on this project. The first one, Neiro Cabrera, worked on this for about a year and then he transferred to UCLA and then he just recently messaged me and told me that he got a job in a related industry,” said Kerney. “An absolute success story. He worked on this. He got experience in it. He found he loved it.”

This sense of discovery is a sentiment that Singh echoes. “When I first joined the industrial automation program here at Clovis Community College, my career goal was to be on the plant floor,” he said. “Working with this project has exposed me to newer and emerging technologies and broadened my horizon and opened me to a lot more opportunities within the field.”

Clovis does not want to gatekeep this knowledge or technology. In an effort to increase the accessibility of the project, Graff and Kerney set up a Github page that details the hardware and software requirements for the project, along with instructions for configuring components as well as lab exercises and training materials. “We want to share everything we have here,” said Graff. “You can take this and use it in a classroom. Or if you're just someone that wants to have a fun automation project, maybe before you hook up your whole home to be a smart home, you can just get a little $55 home from Amazon and pay $100 for a Raspberry Pi, and you'll be set to go.”

Learn more about Inductive Automation's educational initiatives in the blog post "IA’s Efforts To Shape The Future Of Industrial Automation."

Transcript:

0:00:11.5

Matthew Graff: I'm Matthew Graff. I work here at Clovis Community College. I'm an Instructor of Automation, Robotics, Mechatronics. What we do here in the lab is teach students on industrial automation. So a few years ago, I got contacted from a professor at Texas A&M if I wanted to be involved in a National Science Foundation project. And the project was focusing on training technicians in the Fourth Industrial Revolution. So when the grant was awarded, I let my computer science colleague know that there was a position that he could work on this grant with me. The reason I brought the computer science department in is I had no background in working with something like a Raspberry Pi and so I needed that expertise. We brought in multiple student workers over time and they assisted in getting Ignition on the Raspberry Pi, getting the system working, stuff that a computer science student could do pretty easily, but it was just not the background that myself or students in industrial automation program normally have.

0:01:16.3

Bill Kerney: My name is Bill Kerney. I am an Instructor of Computer Science here at Clovis Community College. I've been working on this project for about two years now. My role here was as an advisor. I was here to supervise the student workers on the project. And so, when they got stuck figuring out how to do something, then it was my job to unstick them.

0:01:35.1

Matthew Graff: We are training high school teachers and college instructors on the Fourth Industrial Revolution system or Industry 4.0 Project. And so what we do is we show the students how to initialize the system and then do some troubleshooting. I've been very impressed working with the Educational Engagement Program with Inductive Automation. Just from the get go, I just got on the website and said, "Hey, I'm interested." And within a week, we were talking person to person going, "Hey, this is what we're trying to do, what we need to accomplish." From there they were able to connect us with others in Inductive Automation to help with the project and give some feedback so that we would be doing stuff to industrial standards.

0:02:17.9

Julian Laxamana: My name is Julian Laxamana. I'm currently a Student Researcher here at Clovis Community College working on the Industry 4.0 Project. I work with the Raspberry Pis and Arduinos to collect data from smart homes and display it on the Ignition webpage.

0:02:31.7