Resources

Browse our ever-expanding library of useful articles, case studies, videos, webinars, and more.

Featured

Revitalized Bourbon Distillery Merges Tradition With Innovation

Bourbon distillery Castle & Key implemented Ignition at their facility in Frankfort, Kentucky, with the help of Gray AES to replace an outdated FactoryTalk system. The mobile-responsive Ignition application was Gray AES’ first large-scale project using Perspective, featuring a high-performance HMI, alarming, and reporting, but most importantly access to historical data.

10 min video

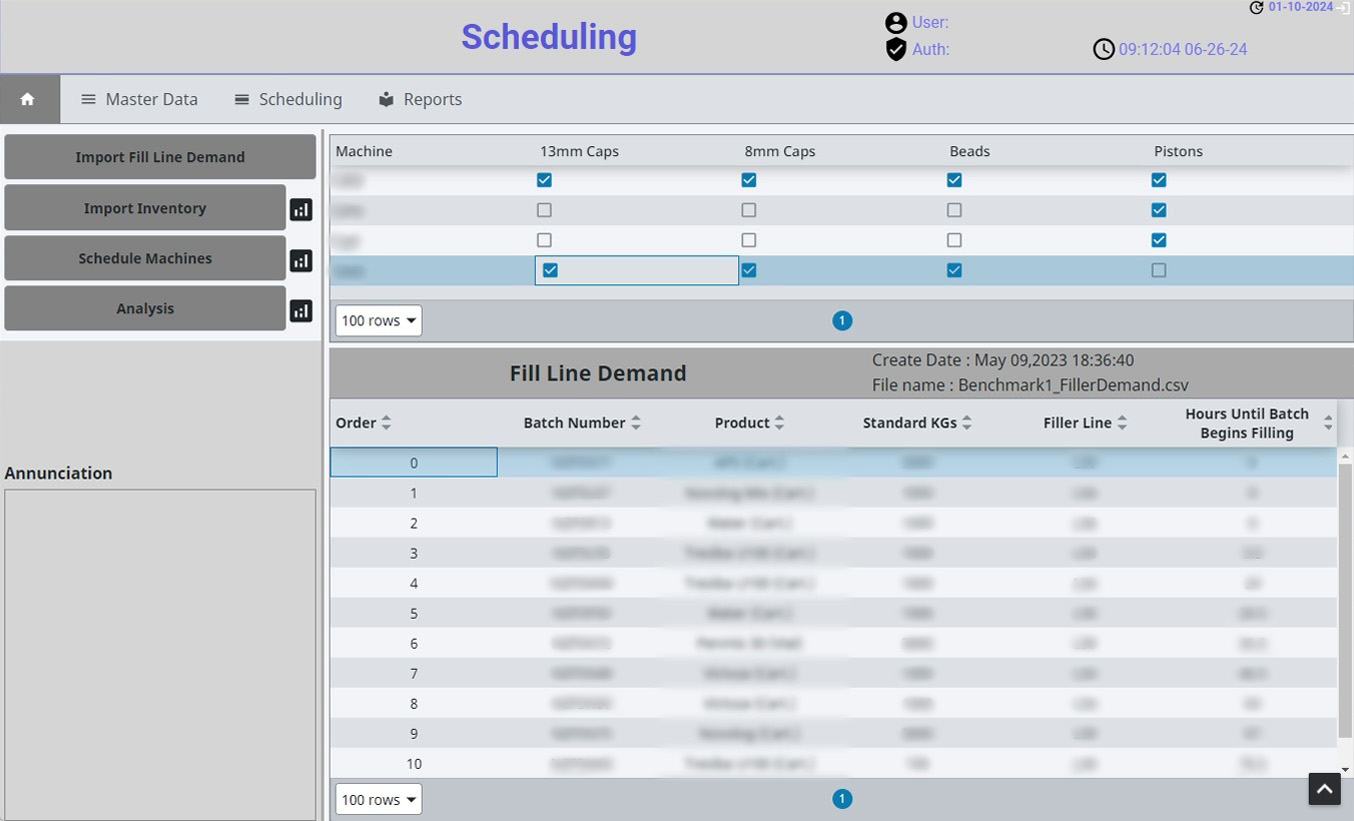

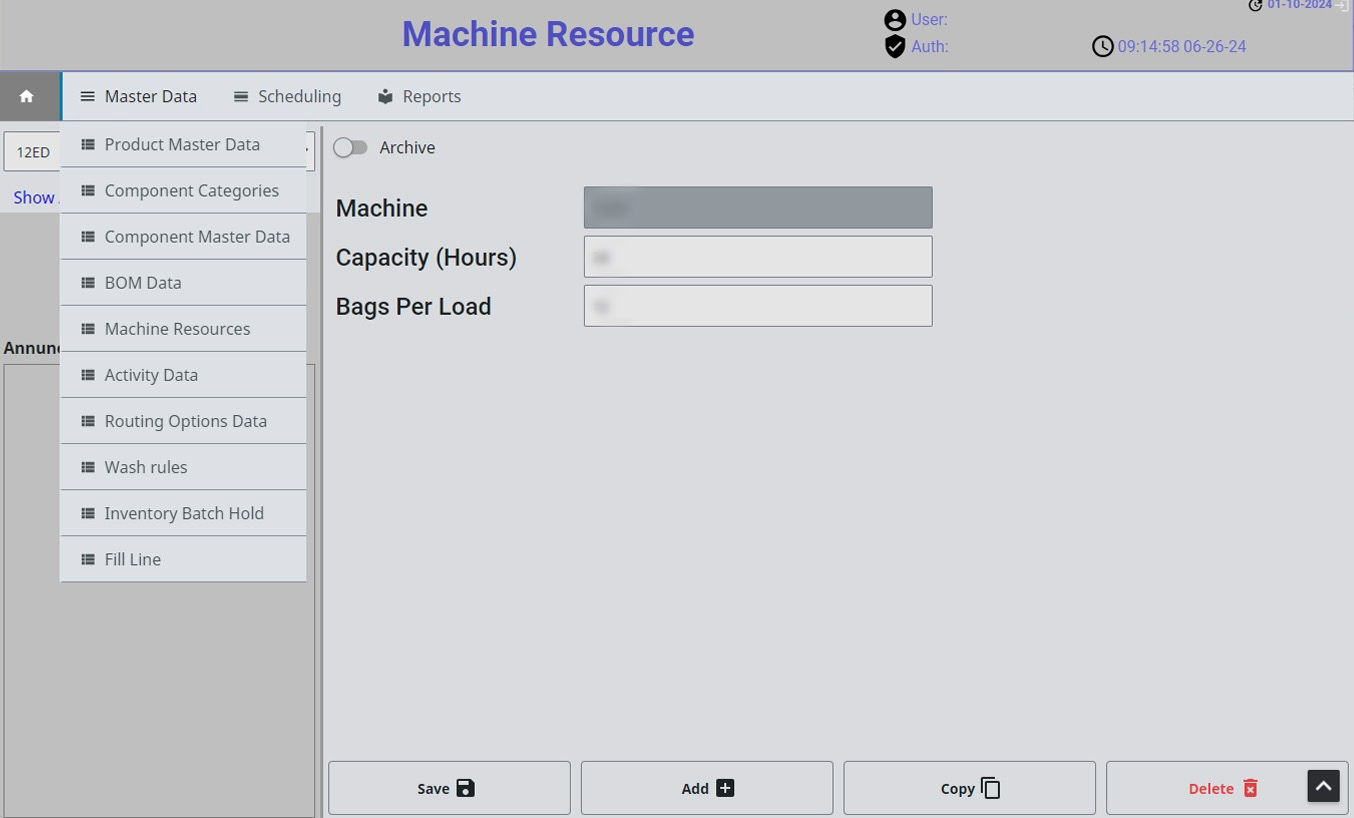

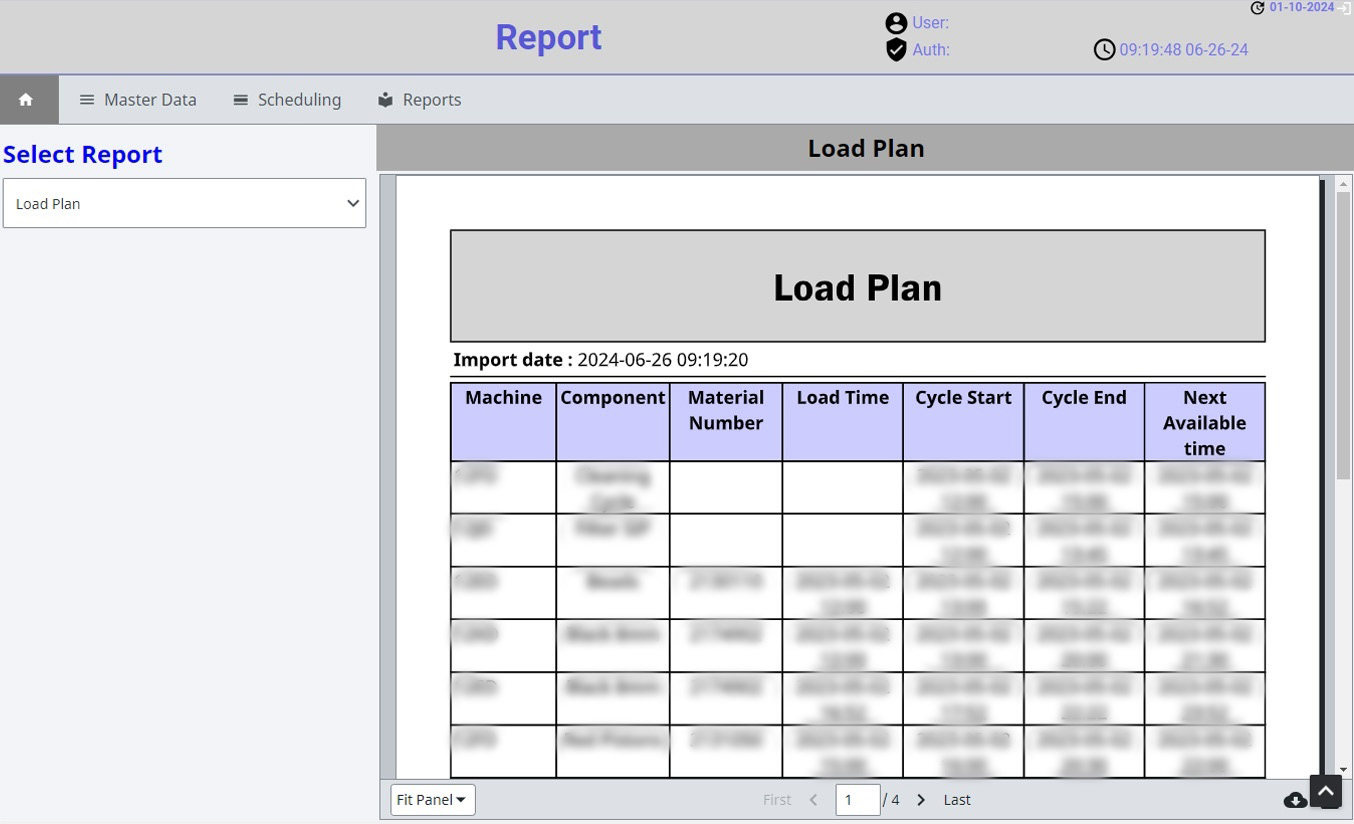

Driving Efficiency and Visibility at rPlanet Earth

rPlanet Earth partnered with Kanoa to implement Kanoa MES — a modular, composable manufacturing execution system built specifically for Inductive Automation’s Ignition platform.

7 min read

Clovis Community College Puts Industry 4.0 Into The Hands Of Students & Teachers

Next to the robotic arms, the off-the-shelf miniature smart homes may not appear to be a key part of Clovis Community College’s Automation, Robotics & Mechatronics lab, but this unassuming hardware is providing students and instructors alike with a unique opportunity to build industry-grade automation applications.

12 min video

Phased Deployment Methods

By leveraging common design patterns and standardized templates, teams can accelerate deployments while maintaining consistency across each environment.

1 min read

Level Up Your Knowledge At The 2025 Ignition Community Conference

If you’re thinking about coming to ICC but haven’t quite made up your mind, or if you’re planning to come for the first time and wondering what to expect, get a sneak peek by watching this free webinar. You’ll learn why ICC 2025 on September 16–18, 2025 in Sacramento, CA is a can’t-miss event and a great investment in your future success!

Tomorrow's Engineers Cook Up A Fast-Food Application: Lessons From A Student Competition

Learn how to structure a working project with ordering interfaces, inventory management, alarming, navigation, and more, and see development techniques, best practices, and clever design tricks that you can apply to your own Ignition projects.

58 min video

Say Yes To Any Automation Project With Ignition

At Inductive Automation, integrators and end users frequently tell us how they’ve completed projects with Ignition that would have been impossible or impractical with any other industrial automation software. In this webinar, experienced integrators will share some of these true stories with you. As you’ll see, adding Ignition to your toolset can take you from having to say “sorry, we can’t” to declaring “yes, we can!”

60 min video

Design Like A Pro: 25+ Hidden Gems That Make Your Project Shine

Join us as two of Inductive Automation’s Ignition experts share insider tips and tricks for building projects more efficiently, working with containers, and tapping into a wealth of knowledge and resources from Ignition’s global community.

58 min video

Clovis Community College Puts Industry 4.0 Into The Hands Of Students & Teachers

Next to the robotic arms, the off-the-shelf miniature smart homes may not appear to be a key part of Clovis Community College’s Automation, Robotics & Mechatronics lab, but this unassuming hardware is providing students and instructors alike with a unique opportunity to build industry-grade automation applications.

12 min video

Going ‘All-In’ With Ignition: Insights From Leading Integrators

In this webinar, a panel of leading integrators will delve into their journey with Ignition — from first learning about it to making it their application-building platform of choice — and how this journey has helped their teams reach new heights of success.

57 min video

How To Choose a System Integrator

As modern organizations look to improve operations with new forms of automation, one question always comes up first: “Where do I start?” Odds are, these days you need an integrator. As experts in connecting OT and IT, control system integrators bridge the gap between the plant floor and information technology. Take a tour of Inductive Automation’s Find an Integrator tool to find which integrator can help you achieve your goals.

5 min video

License To Thrive: Bypass Project Roadblocks With Unlimited Licensing

Join us for this webinar to see what a huge difference Ignition’s unlimited licensing model can make in your future projects!

56 min video

Teaming Up To Enable Digital Transformation & Unified Namespace

This webinar will highlight the benefits of using all partners within the Inductive Automation ecosystem to achieve seamless digitalization and a Unified Namespace (UNS) with reduced complexity and time.

60 min video

How Inductive Automation Uses Ignition

Here at Inductive Automation, we have found plenty of everyday uses for Ignition because it allows us to create customized tools that generate tremendous value. Discover a few of the ways we leverage our own software platform.

17 min video

Water Infrastructure Company Replaces Point-To-Point VPN With MQTT

Goodnight Midstream chose Ignition because it could fulfill several requirements: data mining and business intelligence work on the system backend; powerful Linux-based edge deployments; easy upgrades that could be performed by administrative staff; location data driven by an external database; and template support.

8 min video

Unleashing ROI And Innovation With Ignition

No matter how you look at ROI, Ignition is the best choice for HMI, SCADA, and Digital Transformation software. In this webinar, you’ll find out why that’s true by hearing the experiences of industrial professionals who have worked with Ignition for years.

54 min video

Integrating Ignition with Exciting Peripherals

Ignition is based on open standards, is deployable anywhere, provides data to anyone, and can integrate with virtually any system or device. This allows you to leverage best-in-class technology with seamless integration to Ignition. Perspective and the native iOS and Android application is a perfect example of this. Ignition enables people to extend their applications to a phone or tablet by leveraging the camera, GPS, NFC, Bluetooth LE, and other mobile tools. In this session, you’ll get some exciting use cases and live demos featuring one exciting OT peripheral and one very cool guest appearance you won’t want to miss!

45 min video

Architecting Success With Scalable System Design

Learn about common Ignition architectures, how to customize architectures, and the Ignition Architecture Builder, a powerful resource with tools that help you create, share, and track your architectures in a single project. Additionally, we will discuss Ignition's capabilities beyond traditional SCADA architectures, showcasing its ability to accommodate unique applications with third-party modules, database services, and more.

55 min video

Glass Manufacturer Leverages Hybrid Architecture To Deploy Identical Applications At Multiple Sites

Saint-Gobain Glass mobilized 2Gi Technologie and Plantformance to create and deploy Ignition applications in several countries, within a hybrid architecture of local real-time data and shared data in the cloud. These applications enable Saint-Gobain Glass to have identical applications in its plants to accelerate digitalization and to consolidate data at a global level, as well as leverage data locally for immediate remediation plans stored in Microsoft planner.

9 min video

Infrastructure Provider Builds Demo Platform To Give Clients Dynamic View Of Solutions

Vertiv, an organization that manufactures components and implements automation solutions for data centers and communication networks, used Ignition to create an internal and external demo platform that encompasses all of their go-to market offers and solutions, incorporating both manufacturing facilities and critical regional offices.

10 min video

Edge-To-Cloud Architecture Acquires Real-Time Data From Remote Oil & Gas Facilities

Automation Solutions Ecuador (ASE) developed a cloud-based solution for Smart Energy Applications that enables real-time monitoring, data acquisition, and reporting for Gas-to-Grid (G2G) systems located in remote oil & gas facilities in the Amazon. Smart Energy provides Gas to Grid in a Box (G2G_B) solutions to produce energy using the gas associated with the crude oil extraction process. The G2G_B system uses gas without treatment to reduce carbon footprint. It comprises a generation unit (Waukesha), a control and synchronism unit (Woodward Easygen), and a load shedding unit (Multilin). The project developed by ASE was crucial for Smart Energy to get real-time and historical data of electrical and mechanical parameters, KPIs, and automatic reporting of technical, financial, and environmental results. This allowed Smart Energy headquarters to assess the impact of its solutions. Additionally, the project allowed the solution to be maintained with OpEx instead of CapEx.

5 min video

Power Company Consolidates Diverse Assets With Ignition & Unified Namespace

Dautom successfully addressed the challenge of consolidating diverse power generation assets across multiple geographical areas. By leveraging Ignition as an IIoT platform, implementing Factory Compass 4.0, and the Unified Namespace (UNS) to standardize data models, they achieved operational excellence, resulting in enhanced interoperability and scalability.

10 min video

Automotive Parts Manufacturer Replaces Manual Logging With Fully Automated Ignition System

Murakami’s North American plant produces automotive side-view mirrors, processing plastic into assembled mirrors with included electronics. This project transformed Murakami Injection’s pen-and-paper logging process into a fully Ignition-powered system with automated production, scrap, downtime, and changeover tracking.

9 min video

Electric Utility Expands Ignition System To Oversee Entire Transmission & Distribution Infrastructure

Northern Wasco County People’s Utility District (NWCPUD) had an existing Ignition installation with several projects built by OS Engineering for reporting meter data and operating two hydroelectric power generation projects. To complete their SCADA system, OS Engineering was selected to expand this Ignition installation to include monitoring for over 80 Intelligent Electronic Devices (IEDs) across nine substations. NWCPUD wanted a single SCADA application to oversee all aspects of their transmission and distribution infrastructure, including KPIs and real-time data, along with reporting, alarming, and trending to aid in day-to-day operations.

10 min video

Cloud-Based Control System Delivering Cost-Effective Solutions

Environmental Operating Solutions Inc. (EOSi) designed a reliable, cost-effective control system capable of being deployed quickly for both pilot and long-term projects with a minimal site footprint and impact to operations. Additionally, EOSi aimed to create a user-friendly interface accessible by remote and local personnel.

9 min video

Configurable MES Solution Rapidly Delivers OEE Improvement For Cable Manufacturer

In order to gain more insight into how to optimize line performance, Belden decided to partner with Flexware and utilize their SparkMES™ to rapidly capture and visualize key OEE metrics. This project returned significant ROI for Belden.

11 min video

Island Water Utility Ensures Uninterrupted Service, Improves Compatibility & Scalability

Barbados Water Authority (BWA) implemented a comprehensive SCADA system using Ignition to monitor and manage 55 drinking water stations, nine wastewater stations, and two treatment plants. The project aimed to ensure the provision of uninterrupted and high-quality services while addressing operating system compatibility, scalability, and network issues. Aquatec-Automation designed the SCADA system using the Vision Module for desktop and the Perspective Module for the mobile application.

9 min video

Standardized Interface & Hardware Allow Oil & Gas Company To Rapidly Onboard New Facilities

Edge Controls combined the flexibility of Opto 22 edge devices to standardize field equipment configuration and commissioning with Ignition 8.1, Chariot MQTT Broker, and Perspective, utilizing these standards to rapidly onboard new facilities and provide users with new workflows with a fully mobile-responsive card-based user interface, all while lowering overall costs.

9 min video

Build-A-Thon

Behold, another Build-a-Thon is upon us, complete with all the intrigue, feats of daring design, unexpected surprises, and singing that usually accompany such a monumental event. This year, teams from two top integration companies will battle to see who can design the best Ignition project. Don't miss all the excitement of witnessing the crowning of a new Build-a-Thon champion live at this educational, one-of-a-kind competitive SCADA event!

100 min video

Brewery Optimizes Predictive CO2 Model Built in Ignition

Carlton and United Breweries redeveloped an Excel macro- and VBA-driven predictive CO2 model from beer production in Ignition’s Perspective Module. The model shows the predicted amount of liquid CO2 in storage hour by hour over two weeks. The system also monitors key quality and performance indicators in the liquid CO2 system and provides historical capabilities.

8 min video

Technical Keynote: What's New in Ignition 8.3

Traditionally, we've always held the Technical Keynote or Development Panel on Day Three of the conference, but this year, we've got something big to discuss, so we've moved it up to Day One of our conference content schedule. It's no secret that we've been working on the newest version of Ignition for several years now, and now we're finally able to dive deep into what's coming in Ignition 8.3 and how its powerful new features can lead users to their next big breakthrough idea!

69 min video

Main Keynote: Exploring the Impact of the Ignition Community

The global community of Ignition users includes large multinational enterprises, government and professional organizations, small companies, and individuals. While each uses the software differently, they all use Ignition to harness the power of automation to accomplish their own mission of making something better. In this keynote, we'll explore how Inductive Automation is supporting the efforts of the Ignition Community and the incredible impact their work has on the future and improving people's lives on a regional and local level.

56 min video

The Making Of World-Class Control Systems

This webinar will be a great opportunity to delve into some amazing projects and get inspiration for your own work. By learning from these examples, you can hone your innovation skills to attain greater success in your controls solutions, improve your business results, and truly make your mark on the industrial automation industry.

59 min video

UNS: Unified Namespace

Digital Transformation is all about data, and companies will only achieve this goal if they manage their data differently than in the past. A Unified Namespace (UNS) is the architectural foundation of successful Digital Transformation initiatives because it enables you to make data accessible from your entire enterprise to a single database.

7 min read

Unifying OT & IT Through Seamless Interoperability

On August 29, discover how you can bridge the OT/IT gap through open standard technologies and Ignition’s unlimited connections. You’ll learn how Ignition’s OPC UA Module enables you to break down barriers to connectivity, with drivers for nearly any PLC.

54 min video

Ignition EAM Module: Enterprise Control In One Place

The Enterprise Administration Module (EAM) provides a secure and intuitive way to manage multiple Ignition installations from a single location. While the module is ideal for enterprise systems across vast geographical distances, even companies with a single plant floor can benefit from the EAM’s ability to centrally synchronize projects, monitor performance, as well as automate backup and recovery.

3 min video

Design Like A Pro: 25+ Tips For Lightning-Fast Development

Join industrial automation experts as they share their top tips and tricks for developing applications amazingly fast (and without compromising quality). You’ll learn about functions in the Ignition designer that shorten a project’s timeline, how to speed up scripting, time-saving techniques for using the Ignition gateway, and a whole lot more.

56 min video

Ignition Perspective Module: The Plant Floor in Your Pocket

Build mobile-responsive HTML applications that run natively on any screen.

8 min video

Assembling The Puzzle Pieces Of Digital Transformation

In this webinar, you will see how to build a scalable system for SCADA, MES, IIoT, and Digital Transformation, step by step. Experts from Inductive Automation, Cirrus Link Solutions, Sepasoft, Opto 22, and 4IR Solutions will explain how their respective software and hardware components fit together to create a seamless automation ecosystem within an Ignition Hub and Spoke Architecture.

61 min video

Integrator Roundtable: Building A Successful & Sustainable Future In Manufacturing

This integrator roundtable will be packed with practical, first-hand advice on sowing the seeds of tomorrow’s success in today’s economy. Some of the best integrators across a wide range of industries will share insights on achieving great leadership, actionable tips to finding incredible talent, and what it really takes to create a company culture that cultivates success. They’ll also discuss building sustainable systems, recent challenges in integration, and emerging technologies in industrial automation. Don’t miss it!

54 min video

Iron Foundry Gains Competitive Edge & Increases Efficiency with Innovative Technology

With help from Artek, Ferroloy implemented Ignition to digitally transform their disconnected foundry through efficient data collection and analysis while integrating the new system with existing software and specialized machinery.

11 min video

Accelerating The Journey From Edge To Cloud To Results

In this webinar, find out how an integrated and proven set of technologies can make the edge-to-cloud journey much faster and easier. Industry experts will explain how to drive successful business outcomes through tools like unified namespace (UNS), digital twins, data lakes, KPI visualization frameworks for OEE and other metrics, and a lot more.

60 min video

Getting Started with Ignition

Getting setup with Ignition is quick and easy. And in this video, we'll guide you through some setup to help you get started.

9 min video

Boost PLC & Device Interoperability With New Drivers

On March 28, learn how to remove the limits of what you can connect your system to. You’ll discover how Ignition makes it a breeze to improve PLC connectivity. You’ll get up to speed on the new DNP3, IEC 61850, Mitsubishi, and Micro800 drivers for Ignition. Plus, you’ll have the opportunity to ask any questions related to the drivers or interoperability at large.

60 min video

What Is MES?

Simply put, a MES system is used to monitor and manage work-in-process on the factory floor, covering resource scheduling, production workflows, recipe management, traceability, inventory, quality assurance, document control, and more. A successful implementation of MES software will not only improve efficiency, but make manufacturers into better businesses.

4 min read

How Digital Transformation Starts With SCADA

In today's rapidly evolving industrial landscape, we cannot overstate the significance of a robust and modern Supervisory Control and Data Acquisition (SCADA) system. SCADA systems are at the heart of operational technology (OT), where we find most of the data needed for Digital Transformation. Ignition SCADA bridges the gap between OT and information technology (IT), facilitating the seamless flow of data essential for monitoring, control, decision-making, and much more.

57 min video

NERC CIP Best Practices with Inductive Automation and Ignition

This guide addresses best practices for using Ignition and working with software vendors in a CIP-compliant way, with recommendations based on specific CIP standards.

1 min read

Empower Innovation With Unlimited Licensing

Discover the pure magic of an unlimited licensing model in this webinar, with examples of real-world projects that benefited tremendously from having unlimited tags, clients, screens, devices, and more, for one single, astonishingly affordable price.

55 min video

Build-A-Thon

The conference is guaranteed to go out with a bang as the Build-a-Thon closes out ICC once again. Join us for the conclusion of the ultimate Ignition challenge, where the final two teams compete for the glory of developing the most elevated Ignition solutions and being crowned Build-a-Thon champions. Who will wear the orange winner’s blazer after the votes are all counted? There’s only one way to find out, so stick around to catch the competitive spirit and enjoy an unforgettable music performance from IA’s Department of Funk that you’ll be humming for weeks!

76 min video

Technical Keynote

Developing industry-defining software is no easy task, but someone has to do it. Join our Development team as they highlight recent improvements and upgrades, current developments, and a behind-the-scenes peek at the future of Ignition before answering questions directly from the Ignition community.

60 min video

From LinkedIn Connections to Community Leaders: The Automation Ladies Experience

What happens when two passionate ladies in industrial automation meet on LinkedIn and decide to create a podcast? Magic. And growth, lots of growth. Dive into the journey of the Automation Ladies podcast and how it has become an engine for both business growth and network expansion. Nikki and Ali will unpack how amplifying your voice online can have real-world business benefits. If you want to grow your customer base, attract top-tier suppliers, or strengthen your community, this talk should have some actionable takeaways on the power of creating an authentic personal brand by sharing your journey with the world.

46 min video

An Overview of Ignition’s MongoDB Connector Module

Earlier this year, we introduced a connector module that allows an Ignition Gateway to integrate with MongoDB. This session provides an overview of MongoDB, outlines the connector module's capabilities, and demonstrates how you can most effectively leverage it to elevate the functionality of your existing deployments.

42 min video

Hitting a Home Run with Ignition

Ignition is not limited to industrial applications alone; its powerful features extend to use cases of all kinds. From its intuitive design features to its robust scripting capabilities, you can harness the full potential of its flexible architecture and rich tool-set to create innovative solutions in non-industrial automation development. Witness this potential firsthand through a baseball scoring and statistics app developed entirely in Perspective, while providing examples of how tags, persistence, scripting, and views can be utilized in a non-industrial setting. Our goal is to inspire others to elevate their lives and hobbies in new creative ways with Ignition.

45 min video

The OG Perspective: 10+ Years of Ignition Wisdom and Beyond

In this session, we'll explore more than a decade of experience with Ignition, sharing valuable insights as a long-time member of the Ignition community. We'll take a practical look at how Ignition has evolved and its role in modern manufacturing, including topics like MES, OEE, AI, and more. It's an opportunity to gain practical knowledge and understand the journey from the early days to today's automation landscape.

42 min video

Rising to the Challenge - Adventures in System Conversion

The folks at Flexware are no strangers to a challenge. When the opportunity to convert a large system over to Ignition arose, they took it head on. Join them in this session where they'll talk about the project and share their lessons learned, talk about custom tools, and describe their thought process.

41 min video

Learning Ignition Fundamentals

Whether you're new to Ignition or just want a refresher, this session is made for all. The Inductive Automation Training team covers all the basic knowledge and fundamental features you need to get started with Ignition.

45 min video

Integrator Panel

Which new innovations will prove vital for future success and which flash-in-the-pan trends are destined to be forgotten by ICC 2024? During this panel discussion, some of the Ignition community's most successful integration professionals share how they are responding to emerging technologies and techniques that are driving the evolution of the automation landscape.

44 min video

Using Keycloak with Ignition

Keycloak is an open-source Identity and Access Management solution for adding authentication to applications or services. With Ignition, Keycloak functions as an Identity Provider to authenticate users and define roles to access client/session views.

10 min read

Tyson’s Smart Factory Journey

This session provides an overview of how Tyson has standardized operations with Ignition as a SCADA platform, highlighting and detailing how consistent data and dashboards allow for faster implementations. The talk will also include best practices that Tyson has developed, and will identify some of the key integrations that have helped simplify and streamline data collection processes.

28 min video

Don’t Get Lost in the Cloud: Tips & Tricks for Successful Ignition Deployment and Management

With the release of Cloud Edition, it's never been easier to get Ignition running in the cloud. But are you ready for it? From security concerns to misconfigurations, there are plenty of pitfalls to stumble upon when managing applications in the cloud. But fear not, as help is on the way. Join the experts from 4IR in this session where they'll provide helpful tips and tricks for deploying and managing Ignition in the cloud.

45 min video

Elevate Your OT Data Securely to the Cloud

Ignition Cloud Edition! Awesome! But wait… How can I possibly connect my PLCs or I/O systems to the cloud? Won’t that jeopardize them? And require heavy IT involvement? What’s the payoff? In this session, we’ll discuss how to use Ignition Edge and Ignition Cloud Edition together to quickly create scalable, high-performance, cybersecure architectures for democratizing your OT system’s data. Whether in brownfield or greenfield environments, you’ll unlock the power of edge-to-cloud hybrid architectures that are cost-effective, easy to manage, cybersecure, and deliver more value to your organization.

45 min video

What Is The Ignition Effect?

"The Ignition Effect” is not just about technology, but how Ignition creates a ripple effect that reshapes systems and sparks solutions. This series offers a panoramic view of the transformative power of Ignition told by the people who use it every day. Watch these videos to witness the impact Ignition has on its community and explore what it can do for you!

7 min video

We Love Ignition. But Can it REALLY Scale?

Can it REALLY scale? This is a question we have received for the last 10 years. Delve into the realm of enterprise Ignition rollouts with industry insights from the lens of an enterprise integrator. Uncover the strategies and best practices that accelerate the implementation and ensure the long-term sustainability of Ignition. Don’t just believe us – hear it firsthand from a guest appearance with one of our enterprise end users.

42 min video

Deployment Patterns for Ignition on Kubernetes

Kevin Collins returns to ICC for a demonstration of how to harness the combined power of Ignition and Kubernetes. This session offers an in-depth look at methods for effectively automating deployment, scaling, and managing containerized Ignition applications.

59 min video

Data Centers: How DCIM Improves Your Daily Operations

In this webinar, experts from Inductive Automation and ATS Global will look at those common requirements and present how an open data center infrastructure management (DCIM) solution based on Ignition can help you to comply, and maybe even change the public opinion about Data Centers in the long term. We’ll also present a new Ignition demo for data centers.

46 min video

Separating Design From Development - Using Design Tools with Ignition

Building screens in Ignition is a breeze, but did you know you can design screens even faster by mocking them up using a design tool? Join us for this session as we talk about the benefits of moving the design process outside of a development platform. We'll cover topics such as design vs. development, UI vs. UX, benefits of using design tools, and an introduction to the design tool Figma.

43 min video

Ignition Exchange Resource Showcase

Since the Ignition Exchange’s introduction in 2019, members of the Ignition community have contributed hundreds of resources ranging from pre-built templates, tools, and scripts to Ignition-powered retro arcade games — all available for free. Discover the full potential of the Ignition Exchange as we highlight some of its most valuable assets, including a handpicked sampling of the top Exchange resources developed by IA engineers.

41 min video

Ignition Diagnostics and Troubleshooting Basics

Ignition offers numerous built-in tools for gathering diagnostic information about the health of your system. This session offers an overview of these tools and explains how our Support Division leverages this information during the troubleshooting process. By the end of this session, fixing problems will feel like shooting code in a barrel.

46 min video

Introduction to Automated Testing of Perspective Projects

Learn the most effective ways for leveraging automated testing to safeguard your development-to-production process. This session will start by outlining how the core tenets of testing apply to automated testing, leading directly into best practices for verifying that your Perspective project development is production-ready.

38 min video

Industry Panel: ICC 2023

61 min video

I4.0 Accelerator for Driving Edge to Cloud Business Outcomes

Come and learn with Cirrus Link and Snowflake what your data has to say. Snowflake, Inductive Automation & Cirrus Link have partnered to provide Data Cloud Solutions. With Ignition UDTs, MQTT, and Sparkplug, discover how easy it is to leverage Snowflake’s platform to gain derived data insights immediately through native AI tooling. Learn about the impact of the recent partnership of NVIDIA and Snowflake. See how this disrupting technology, in conjunction with Ignition, will elevate and simplify your journey to data insights.

49 min video

Sepasoft MES Orchestration for Digital Transformation

Manufacturing workflows are required to execute critical processes the right way – every time. The correct tasks must be carried out in the correct order, with the correct materials, approvals, quality checks, and accurate records, especially in regulated industries (e.g., 21 CFR Part 11). This objective, and true Digital Transformation, can only be accomplished with a platform that is integrated, agile, low-code, and feature-rich. Join us for a demonstration of our various MES offerings to showcase Sepasoft’s orchestrated workflow solution.

43 min video

What's That in the Sky? An Intro to Ignition in the Cloud

Is it a bird? A plane? No, it’s Ignition! There’s enough buzz around deploying Ignition in the cloud, you’d think it would give your system super powers. But does a cloud deployment align with your organization’s grounded, realistic objectives? In this session, we’ll introduce cloud deployment concepts, discuss which architectures and scenarios benefit the most from cloud-based integration, and share real-world Ignition use cases.

46 min video

Main Keynote: Elevating Automation

Let's kick off the 2023 Ignition Community Conference on a high note. Join Inductive Automation's leadership team as they reflect on the past year, look toward the future, and give you a bird's-eye view of our growing company, ever-evolving industry, and thriving Ignition community. This is ICC, elevated!

98 min video

New Possibilities at the Edge

As industrial organizations do more at the edge of the network, important new questions are arising. What is the relationship between edge systems and centralized systems? What can you do at the edge that you couldn’t do before? How can you use the edge with the cloud effectively?

47 min video

Global Collaboration Helps Steel Manufacturer Implement Centralized Control Room

The main purpose of Uddeholm, a Voestalpine company, is to manufacture high-quality industrial steel tools, applying best practices for an efficient use of resources and a sustainable development. This strategy has led Uddeholm to become the world’s leading steel tool manufacturer with more than 350 years of innovation and presence in more than 90 countries.

5 min video

All Equipment And Recipes Across 10 Lines Monitored With Single Project

This Ignition project came as a result of a controls-focused project on increasing OEE across 10 packaging lines, specifically monitoring two aspects of production. The first was trending the speeds of each piece of equipment on the line to allow users to monitor the V-Curve over time. The second was maintaining equipment recipe data and tracking when changes were made.

6 min video

Glass Company Increases Profitability With True-North Metrics

HMI Glass was facing numerous challenges impacting profitability, leading to reduced earnings before interest, taxes, depreciation, and amortization (EBITDA) since 2018. The scope of the project was to utilize intelligent manufacturing data to implement a lean management model and drive cultural transformation. The success of the project was tied to fees based on performance and utilized a gainshare model based on a cost of poor-quality improvement.

10 min video

Real-Time Data & Custom Drivers Allow Power Supplier to Anticipate Demand

First Gen is one of the oldest and largest conglomerates in the Philippines that has an interest in power generation and power distribution. While Energy Development Corporation is a diversified renewable energy company, both are under the First Philippine Holdings Corporation – A Lopez Group of Companies, who constantly strive to meet the needs of its customers. In June 2021, the Enhanced Wholesale Electricity Spot Market Design Operations (EWDO) was launched. This officially started the new regulations for shortening of the dispatch interval: instead of a per-hour basis, it was transitioned to a five-minute interval. First Gen and Energy Development Corporation (EDC) have adapted the five-minute interval in their Central Dispatch Operations (CDO). This new regulation was addressed by installing multiple Ignition gateways for faster data monitoring, collection, and secured control of power generation across more than 30+ power plants (and counting). Controtek developed customized drivers to get the real-time dispatch setpoints from the Independent Electricity Market Operator of the Philippines (IEMOP) to meet the demands of the operations and compliance with the new regulation of the EWDO.

12 min video

Digital Troubleshooting Guide Boosts Chemical Company's Efficiency

Cooley Group has a corporate Manufacturing 4.0/Digital Transformation initiative that it is implementing using the Ignition platform. RoviSys was brought on to help guide Cooley Group on this journey and develop the functionalities it needed in a templatized way that promotes scalability and supportability. Cooley Group requested the use of Ignition to develop a Digital Troubleshooting Guide that operators could use to help resolve downtime events impacting their OEE. For this project, RoviSys implemented a creative solution that gave Cooley Group exactly what it asked for, yet made it easy for it to build and configure on its own within the Ignition designer.

3 min video

Water Utility Seamlessly Transitions Operating Systems and Speeds Development

Design and develop a new treatment plant HMI to replace WinCC and condense third-party applications into one platform.

9 min video

Reliable Data Supports Cleaner Energy Initiative For 50 Sites

One of South Jersey Industries’ (SJI) key initiatives is to deliver on its commitment to provide cleaner energy. The generation of renewable natural gas facilities at dairy farms is a key production commitment for SJI. A modular production facility is required at each farm site, near the raw materials. The speed of deployment and number of sites involved demands the establishment of a universal architecture and platform for the integration of control and enterprise systems at the company. In addition, the distributed nature of the system and criticality to the energy infrastructure demand the highest level of security and reliability. Finally, SJI requires that all these sites be centrally monitored from an enterprise SCADA system that will also historize data for financial and regulatory reporting. The central importance of reliable data for continual operational financial justification proves the common Digital Transformation adage that “data is the new gas.” SJI Industries tasked InflexionPoint to build a foundation for the application of key control and information technologies and systems that will allow the organization to realize world-class Digital Transformation and create a secure data pipeline. In doing so, SJI would be able to provide users at all levels of the organization with access to control system information. Through the strategic application of industrial information technologies, significant benefits are realized in the following areas: reliability, availability, visibility, and security. InflexionPoint successfully built and deployed this operational technology stack on Inductive Automation’s Ignition platform, which let ACC establish a scalable architecture to support plants/sites of varying sizes and complexity. The integration of data from the site’s control level, through various secure (DMZ) network layers to the corporate core network and cloud providers, has been addressed.

10 min video

Enterprise SCADA Gives New Zealand Meat Producer Standardized Control

Tamaki Control implemented a new Ignition Perspective standards framework for ANZCO Foods. This framework replaced unsupported SCADA systems and enabled new automation projects and ERP API integration solutions across its 10 manufacturing and processing sites in New Zealand. The project involved upgrading or installing Ignition 8.1 at each site and connecting them on the Gateway Network through an enterprise architecture with the Enterprise Administration Module. The result is a cohesive and efficient system that has positioned ANZCO Foods for continued success.

10 min video

New Control System Improves Safety And Compliance For Pharmaceutical Company

Initially, Zendal approached Optomation Systems to tackle their needs for monitoring unmanned storage units holding pharmaceutical final products for their customers. When Optomation introduced Ignition, it rapidly evolved into a larger project with a broader scope to encompass the data acquisition of varied equipment, process control and supervision, alarm notification, data historization, and automatic report generation. The main objective of the project was to implement a system that acts as a data repository for the information collected from the dedicated equipment in the different production areas and auxiliary services, both to satisfy regulatory requirements and prove compliance with CDMO obligations to customers. In addition, the system integrated new production areas into the system and expanded functionality to include control and supervision of several processes. Field devices and sensors are connected to controllers that execute automated sequences, and from Ignition, operators have full access to the operation, just like a traditional SCADA system.

10 min video

Defying Ordinary: A Deep Dive Into Unique Automation Projects

Every year, Inductive Automation shines a spotlight on modern marvels in industrial automation at the Discover Gallery, but there’s a whole lot more to these projects than we could ever capture in the showcase. In light of that, we’re diving deeper into some of this year’s most novel Ignition projects.

48 min video

Expanding Connectivity with Ignition’s Mitsubishi Driver

We are continually expanding Ignition’s capabilities, adding new features, updates, and drivers. With the release of Ignition 8.1.31 this month, Ignition’s new Mitsubishi Driver now adds the MELSEC-F devices to its growing list of compatible MELSEC series, including the iQ-R, iQ-F (FX5U), Q, and L series. This latest addition is more than just an increase in compatibility, it’s a step toward making the Ignition platform more effective globally.

46 min video

What Is a Panel PC?

Most people are familiar with PCs (Personal Computers), but far fewer understand the difference between a retail PC and a panel PC. Whereas PCs are typically found in offices, panel PCs are specialized units designed to be used on or near machines in industrial environments like plant floors or remote sites. Panel PCs are built specifically to run HMI/SCADA software that allows operators to monitor and control processes in virtually every industry, including food & beverage, oil & gas, automotive, water & wastewater, and many more.

4 min read

Design Like a Pro: Exceptional Industry-Specific HMIs

When it comes to designing an HMI, there are a few basic concepts to keep in mind, but no one-size-fits-all solution. Every screen will be unique, with functionality and requirements particular to the needs of its operators, and the more specialized the use, the more critical those differences are. So what makes an HMI excel in an industry setting?

58 min video

How’d You Get Here with Kevin McClusky: A Professional Journey

In this new segment of How’d You Get Here, Kevin McClusky chats with Arnell J. Ignacio to discuss Kevin’s professional journey. They talk about Kevin’s early experiences at Inductive Automation to where he currently is now. Kevin also shares insight of the early days at Inductive Automation, what makes IA such a unique place, his journey at Inductive Automation, and much more. We also get a peek into Kevin’s interests and what he is excited about.

50 min episode

Ditch Data Silos: Create a Unified Namespace with Ignition UDTs & MQTT

Data management can sometimes seem like the Wild West, with the chaos caused by inconsistent conventions for naming and organizing data. The current manual and point-to-point data entry methods used in the manufacturing industry result in inefficient operations, difficulty scaling, and dreaded data silos that make it hard for people to share information.

56 min video

How’d You Get Here with Paul Scott: A Professional Journey

In this new installment of How’d You Get Here, Paul Scott sits down with Arnell J. Ignacio to take a trip back in time to explore Paul’s professional journey. They talk about Paul’s early experiences at Inductive Automation to where he currently is now. Paul also shares insight about what it is like to work at Inductive Automation, what makes IA such a unique place, her journey at Inductive Automation, and much more. We also get a peek into Paul’s interests and what he sees for the future.

43 min episode

Ignition Community Live: Ignition Cloud Edition

Hotly anticipated since it was first teased at ICC 2022, Ignition Cloud Edition combines the power of Ignition with the convenience of the cloud. Join some of our Ignition experts as they answer questions from the Ignition community, and explain the best uses for Cloud Edition as well as how it compares to the standard Ignition platform.

66 min video

Ignition + Docker: How to Use Containers for Faster Development

In the never-ending quest to develop and deploy automation projects more quickly, containers represent a powerful leap forward — especially when paired with Ignition. In this webinar, thought leaders from Inductive Automation and the Ignition community will discuss effective ways to use Ignition with the Docker platform, which is widely regarded as the de facto standard for building and sharing containerized apps.

56 min video

Building Businesses and Relationships With Ignition

Rafey Shahid from Qanare Engineering joins Don Pearson to talk about the influence that Inductive Automation and Ignition has on his career. Rafey shares his early days of integration, how he found Ignition and its impact on his business, and the relationships he has developed over the years. Rafey and Don also discuss the challenges and opportunities Rafey has faced and what the future looks like for Qanare Engineering.

35 min episode

Supercharge Your Power Monitoring with Ignition + IEC 61850

One of the defining features of the Ignition platform is its interoperability and now with the IEC 61850 driver, Ignition can natively connect to virtually any IEC-enabled device. Leveraging this new driver, Ignition can supercharge power-monitoring applications through a combination of expanded functionality, increased flexibility, and Industry 4.0 technology.

53 min video

How’d You Get Here with Peggie Wever: A Professional Journey

Peggie Wever joins Arnell J. Ignacio to talk about her professional journey at Inductive Automation. In this discussion, they explore Peggie’s experiences from the early days all the way to her current role. Peggie also shares insight about what it is like to work at Inductive Automation, what makes IA such a unique place, her journey at Inductive Automation, and much more. We also get a peek into Peggie’s interests and what she sees for the future.

25 min episode

How’d You Get Here with Jason Waits: A Professional Journey

Jason Waits talks with Arnell J. Ignacio about his professional journey at Inductive Automation. In this discussion, they explore Jason’s experiences from the early days all the way to his current role as Chief Information Security Officer. Jason also shares what it is like to work at Inductive Automation, what makes IA such a unique place, his journey to becoming the Chief Information Security Officer, and much more. We also get a peak into Jason’s interests and what he sees for the future.

29 min episode

Breakthrough Batch Manufacturing Solutions

Batch manufacturing has not seen major innovation for decades – until now. Creating batch solutions that include process graphics, communications to business systems, traceability, e-signatures, and WIP inventory historically required purchasing and interfacing together several separate software packages, resulting in inconsistent production quality, difficulty making recipe/batch changes, and struggles to comply with regulatory requirements. Finding the right tools to conquer these challenges is key to unleashing your production’s full potential.

56 min video

Educating the Next Generation of Manufacturing Engineers

Jake Hall, also known as the Manufacturing Millennial joins David Grussenmeyer for a great discussion on the outlook on education within the manufacturing industry. They dive in and discuss the effects of the OT and IT convergence in manufacturing, the new generation of manufacturing engineers, and how education is evolving to meet today’s manufacturing needs. Jake and David also talk about the challenges of education and how the pandemic revealed opportunities in manufacturing.

41 min episode

Design Like a Pro: Mobile-Responsive HMIs for Any Screen

Mobile apps have become exponentially more important as smart phones and tablets continue to advance and become the dominant computing devices around the world. This means creating an app that is easy to navigate, visually appealing, and functionally consistent is more necessary than ever before. However, there is no user manual to tell you what to include in your mobile app or what structure is best for your purposes.

55 min video

21 CFR Part 11 and Pharmaceutical Best Practices with Ignition

This guide addresses Food and Drug Administration (FDA) 21 CFR Part 11, Data Integrity and Good Automated Manufacturing Practices (GAMP). It provides best practices and guidelines supporting regulated Ignition applications in the life sciences and pharmaceutical industries.

1 min read

Ignition Community Live: Ignition Certification Update

Join us as we explore the details and timeline of the new Certification process, what this means for integrators in the Integrator Program, and the reasons behind the change, as well as addressing any questions from the Ignition community.

56 min video

How’d You Get Here with Kathy Applebaum: A Professional Journey

Kathy Applebaum joins Arnell J. Ignacio to talk about her professional journey at Inductive Automation. In this discussion, they explore Kathy’s experiences from the early days all the way to her current role as Software Engineering Department Manager. Kathy also shares insight about what it is like to work at Inductive Automation, what makes IA such a unique place, her unusual journey to becoming Software Engineering Department Manager, and much more. We also get a peak into Kathy’s diverse interests and what she envisions for the future.

28 min episode

Harnessing the Power of Edge-to-Cloud Architecture

Cloud-native applications have supercharged industrial systems with previously unthinkable levels of storage space and computing power.

59 min video

De-Risk Your Digital Transformation — And Reduce Time, Cost & Complexity

Although many manufacturers want to get a Digital Transformation project going, they feel hesitant about investing major time and effort into a project that may not deliver the desired results. However, just imagine if you could achieve a quick win for Digital Transformation in only 90 minutes!

60 min video

Back In-Person at ICC X: Insights From the Ignition Community

Arnell J. Ignacio of Inductive Automation sits down with guests from Blentech, 4IR Solutions, NetApp, OnLogic, DMC, Flexware, NV Tecnologías, Streamline Innovations, Qanare Engineering, Vertech, and Automation Professionals LLC. In this podcast, Arnell and guests dive into what it is like being back in person at ICC, their challenges and accomplishments during the pandemic, what to look forward to at ICC, and the future outlook of the industry.

77 min episode

Numerous Custom Applications from One Platform for Provider of Gases, Materials, and Equipment

The customer suffered from a classic corporate administrative problem: too many of its critical processes were managed by a hodgepodge of spreadsheets and paper records. Off-the-shelf products solved some of these needs but were too inflexible to be adapted to the custom internal procedures. Ignition allowed custom applications to be built to satisfy these needs and gain wide community acceptance and shape corporate policy and culture.

8 min video

Cloud-Hosted Enterprise SCADA for Large Provider of Aggregate Material and Cement

Dolese Bros. is a large provider of aggregate material and cement throughout the state of Oklahoma. Over the past several years, Dolese has upgraded many of its quarries with advanced automation, networking, and operational systems. A key component of this strategy is the deployment of Inductive Automation’s Ignition platform at each quarry, and then a cloud-hosted enterprise-level Ignition system to provide reporting, visualization, and business system integration at a corporate level. Dolese enlisted the help of Industrial Networking Solutions (INS) to accomplish their goals.

5 min video

New SCADA Improves Productivity for Biomanufacturing Company

National Resilience Inc. offers a broad mix of customized manufacturing and development capabilities at their Mississauga, Ontario facility to serve the needs of biopharmaceutical companies at all stages of the drug development process – from pre-clinical development to commercial supply. Resilience requested Grantek’s assistance to develop an Ignition SCADA to support new GMP manufacturing processes in the building area known as the “H-Area.” This solution was needed to rapidly scale a brownfield contract pharmaceutical manufacturing facility, allowing Resilience to maximize their productivity and meet their commercialization goals.

6 min video

Improved Monitoring of Power Generators Nationwide

Brown Engineers developed a USA-branded solution specific to their needs for monitoring a nationwide fleet of generators for high-reliability customers.

8 min video

Industry Leader Reduces Paper, Gets Faster Reporting and Better Productivity

This project was created by FG Automação Industrial for Saint-Gobain, a world leader in the design, manufacturing, and distribution of materials and services for the construction and industrial markets. To better attend to their customers' needs, FG Automação Industrial used Ignition Perspective and Sepasoft's OEE Downtime modules. By combining these modules, they were able to transform the Saint-Gobain tube production management process into a robust, user-friendly, dynamic, reliable, and 100% digital interface.

7 min video

New Mobile Capabilities for United Airlines at Houston Airport

In addition to the HMI baggage handling system Vision application running on the workstations for Houston Terminal C/E (and now B), the intent was to offer the same functionality on a mobile device, such as a tablet. While incorporating the same security roles as the Vision application, the operator on the tablet can view/acknowledge/shelve alarms, view graphics, view and interact with device statuses and controls, view statistics and view connection status details from the new Perspective application.

9 min video

Variety of Connections and Unlimited Licensing Aid Cancer Therapy

This project involved using Ignition in the personalized medicine industry to handle multiple communication protocols in one 21 CFR Part 11-compliant environment. The same regulatory data integrity requirements exist in personalized medicine as in large-scale productions and Ignition has proven to be a valuable tool because of its flexibility, mobility, and above all — device integration.

5 min video

Improvements Beyond Expectations for Global Leader in Beauty & Wellness

This project was developed for a greenfield site, built for the manufacturing of beauty and wellness products. The customer had outgrown their original site and had to expand their production to meet demand. The new site had to provide a solution with improved visibility on their systems, services, and manufacturing processes, and provide consistency in the quality of their manufacturing procedures.

7 min video

Improved SCADA, HMI, and MES for Ninth-Largest Craft Brewer in United States

Stone Brewing is the ninth-largest craft brewing company in the US, located in Escondido, CA, and was founded by Greg Koch in 1996. The goal of the project was to upgrade the existing Siemens BRAUMAT brewing automation system with a new design consisting of Rockwell PLCs, networks, Ignition HMI, historian, batch, and MES software for the two brewhouses at Stone Brewing Company in Escondido, California.

6 min video

Lower Costs, More Data for Australian Water Agency with Over 300 Sites

A regional municipal council has implemented the next generation of remote telemetry monitoring and data-driven decision-making. This represents a significant step for the water industry in Australia and provides access to the same data-driven decision-making process used by large water authorities for a fraction of the cost. Since implementing the new system, the council has seen the commencement of significant cost reductions, improved planning, and data-driven decision-making

7 min video

Global Automotive Machinery Company Gets Single Source of Truth in Every Department

Ignition is used to create a SCADA/MES application that replaces a lot of separate Excel sheets and an old Citect SCADA platform. By using Ignition, AT-Automation instead created a single source of truth for every department (production, process engineering, technical service, quality, logistics) within the company.

7 min video

Enterprise SCADA Streamlines Processes for Renewable Energy

SB Energy engaged Vertech to provide a world-class enterprise SCADA solution for their new remote operations center. They needed a single-platform SCADA system to oversee six solar locations across North America and report industry-standard KPIs and data analytics in real-time.

9 min video

New SCADA and Greater Mobility for Large Water-Management Agency

The evolution of Réseau31 agents' missions requires more and more mobility and access to management and supervision tools using mobile terminals (smartphones, tablets). In addition, the rapid changes in the infrastructure to be monitored and operated (organic changes in the network, maintenance, new contracts, etc.) require frequent changes to the applications.

7 min video

Data from Numerous Processes Aids Large Salmon Producer

This project has been developed by employees at the automation department of Nordlaks Produkter AS for the Nordlaks group. The project consists of several departments where operators can control entire processes and managers can extract information and data all the way down to the component level.

8 min video

Largest Publicly Traded U.S. Water/Wastewater Company Benefits from Enterprise Solution

More organizations are bringing Information Technology (IT) and Operations Technology (OT) together to assist in business decisions at every level of the organization. American Water teamed up with Flexware Innovation and Automated Controls Concepts (ACC) to create an Ignition ecosystem for SCADA/HMI standards, central data collection and analysis, and integration with other backend systems to support data-driven decision-making across the company. This project was the first and largest-scale standardization of their operational technology systems, and consisted of converting an outdated SCADA system to a modern system that is ISA 101-compliant. Ignition Perspective and Cirrus Link MQTT modules were included as key parts of this solution.

9 min video

UK’s Leading Leather Manufacturer Has Better Data, Better Results

The project allows Scottish Leather Group to track rawhides through an intake fridge system, and categorizes these hides based on their food grade, weight, gender, origin and status to intelligently fill the fridge rails. An outfeed selection algorithm helps operators choose the best available hides for a given fridge outfeed job (i.e. lime processing, recirc, etc.).

10 min video

Build-A-Thon

The 2021 Build-a-Thon was the first ever to feature members of the Ignition community battling it out head-to-head. This year, we invited all of Inductive Automation’s Premier Integrators to apply for a chance to wear the Build-a-Thon blazer, and after three rounds of challenges, the final two integrators, DMC and Roeslein & Associates, will face off at the conference.

61 min video

Running Ignition in a Container Environment

Leveraging Docker can be a powerful technology for rolling out large systems and setting up flexible development environments. In this session, you'll hear practical tips for running Ignition in a container environment from Inductive Automation's Docker expert.

45 min video

How Far We've Come - Ignition Across the Enterprise

Ignition was always great for solving problems and beloved by Operations. But could it scale? Could it be deployed across an enterprise? Could it stand up to scrutiny in the boardroom while execs are aligning on their digital strategy? Absolutely. Over the past several years, Brock Solutions has been deploying Ignition across enterprises, helping customers accelerate their digital transformations. But don't take it from Brock; hear it from our customers' mouths about how and why Ignition has become the real deal in their enterprise landscape.

42 min video

Performance Tips & Tricks for Optimizing Gateway Networks

Getting the most out of your Ignition gateway network is important to your system’s performance, especially for large implementations. In this session, you’ll get expert tips about how to optimize the performance of your gateway network for heavy workloads.

60 min video

Stone Brewing Successfully Implements Modern Batch System

In this session, Stone Brewing and Wunderlich-Malec Engineering will showcase the first successful implementation of Sepasoft’s Batch Procedure Module. Going into the project, Stone Brewing hoped to upgrade to a flexible and modern batch system that could handle complex recipes. With the support of Wunderlich-Malec, Stone Brewing easily configured the module to replicate existing processes. Attend this session to learn about Stone Brewing’s quick adoption of Batch Procedure and more project highlights.

47 min video

Ignition: The New Enterprise Connection Platform

The quest for greater productivity and reduced costs is driving market forces and investments into new projects trying to combat today’s challenges from the supply chain, labor, and inflation. Learn how Ignition has advanced from the “New SCADA Platform'' to become the standard tool for OT-to-IT Enterprise Digital Transformation. The session will discuss and demonstrate how Ignition with MQTT/Sparkplug is the “Swiss Army knife” Digital Transformation platform from the edge to the cloud to achieve these goals. Get your Enterprise ready to Xperience and Xplore the serendipitous nature of your OT data!

48 min video

Modern Cloud Deployment Strategies

With the systems getting larger and the need for flexibility increasing, effectively running Ignition in the cloud can be a powerful deployment strategy. In this session, Inductive Automation’s architecture experts will talk about how to utilize the cloud for modern deployment strategies.

48 min video

Drain The Data Lake - Model And Contextualize Your OT Data at the Edge

Join a panel of Ignition community experts who helped the State of Indiana launch a Digital Transformation program for manufacturers quickly and simply. Energy data, manufacturing output, and other OT data can be collected and modeled in-plant, and efficiently published into cloud infrastructure and unsupervised AI for actionable insights with a pre-built “I4.0 in a Box” solution.

48 min video

Integrator Panel: How Integration Has Changed & Where It's Going

This panel will bring together some of the Ignition community's most accomplished integrators to discuss how the industry has shifted over the past decade and what technologies and practices will be vital in the future. From IIoT-enabled hardware and cutting-edge security tools to eliminating paper from the plant floor, changes in the last 10 years have altered how integrators approach business and opened up new opportunities. But which areas still have room for refinement and innovation? Hear experienced professionals give their insight and answer your questions about the industry's past, present, and future.

45 min video

Unlocking Innovation & Delivering New Services Through Digital Transformation

Digital Transformation has accelerated as a result of the pandemic as nearly every industry and every company has had to adapt to changing work conditions, market conditions, and environmental conditions. Those companies that are thriving in this new normal have uncovered new value in leveraging technology to accelerate innovation cycles and deliver entirely new products, services, and even business models. Imagine fully recovering from this pandemic better off than before it started with entirely new revenue streams that fill the revenue gaps with even greater profitability through new channels. Learn how this can be done and hear the stories of companies who have succeeded.

45 min video

Industry Panel: Exploring Digital Transformation

It takes coordination to revamp processes or upgrade machinery, but it’s a far more complicated task to establish change all the way from the plant floor to the C-suite. While the necessary Digital Transformation of manual operations may look different across a variety of industries, the critical benefits of increased stability, flexibility, and security remain consistent. Hear from a panel of industry thought leaders and experts as they explore how enterprise-wide solutions have led their companies to a new level of growth and answer your questions about large-scale Digital Transformation.

64 min video

Technical Keynote & Developer Panel

This year, the co-creators of Ignition, Colby Clegg and Carl Gould will be expanding the traditional developer panel into a new format. In this new Technical Keynote, Colby and Carl will cover the recent progress of Ignition and look at the roadmap for the near future of the platform. They will also get some help from a few Software Engineering Division all-stars to give further insight into specific aspects of the platform like security, advanced analytics, and design tools.

65 min video

Overcoming Digital Transformation Pain Points

In order to succeed at Digital Transformation, organizations must plan and carry it out at the levels of process, technology, and culture. Because it is an all-encompassing and ongoing endeavor, the pain points associated with Digital Transformation can be more complex than those you’d encounter when doing something like a SCADA system upgrade or a first-time OEE project.

60 min video

How’d You Get Here with Colby Clegg - A Professional Journey

Colby Clegg joins Arnell J. Ignacio to talk about his professional journey at Inductive Automation. In this discussion, they explore Colby’s experiences from the early days all the way to his current role as CEO. Colby also shares insight about what it is like to work at Inductive Automation, what makes IA such a unique place, his journey to becoming CEO, and much more. We also get a peak into Colby’s interests and what he envisions for the future.

43 min episode

How Ignition Eases SCADA Pain Points

Although SCADA systems are the backbone of modern manufacturing, they are not immune to pain points. While new difficulties have arisen with the need for enterprise-wide Digital Transformation and implementation of IIoT-enabled technologies, many of the issues afflicting integrators and end users have persisted for years.

43 min video

Ignition Community Live: What to Expect at ICC X

This year’s Ignition Community Conference (ICC) is right around the corner! Join us for a behind-the-scenes look at ICC X that will help you to truly make the most of it, whether you plan to attend virtually or in person.

45 min video

The Forces Behind the Digital Transformation

Jeff Winter from Microsoft joins Don Pearson for an interesting discussion on the forces that drive Digital Transformation. They will dive in and discuss the forces of consumer demand and government investment into manufacturing. Jeff and Don will also talk about the power of innovation, the ongoing impact of artificial intelligence, and how to harness the never ending stream of data. You may access the video version of the podcast here.

43 min episode

New Ignition Features In Action

Ignition 8.1 was released in late 2020, bringing many exciting new features like Perspective Workstation, Perspective Symbols, Power Chart, and plenty more. Ignition 8.2 will still be in the works for a while, but that doesn't mean that you have to wait long for new features and improvements. The Ignition software development team puts out “release train” updates nearly every month, and each one comes loaded with significant features that are based on user requests.

56 min video

Ignition Community Live: Ask a Sales Engineer

The Ignition community always asks outstanding questions about industrial automation, software, and technology. For our second installment of “Ask A Sales Engineer,” Co-Director of Sales Engineering Travis Cox will answer attendees’ questions, whether about SCADA, HMI, IIoT, digital transformation, machine learning, Ignition, or beyond! With such a wide range of important topics, missing this webinar is out of the question.

55 min video

Solving Data Problems to Accelerate Digital Transformation

One of the biggest Digital Transformation challenges companies face is how to make the most of their data. Problems like stranded data, lengthy setup times for systems, and difficulties bringing IT and OT data together inhibit an organization’s ability to gather insights. Without these insights to fuel the decision-making process, many companies end up stalled on their Digital Transformation journey.

59 min video

The People Behind Digital Transformation

IA’s very own Don Pearson sits down with Arnell J. Ignacio to explore the people-driven aspect of Digital Transformation. They discuss how Digital Transformation is more than just implementing technology and why motivated professionals are so important to its success. Don and Arnell also talk about the Digital Transformation effect on company culture, the processes people adopt, challenges people face, the business implications, and the business value.

33 min episode

Digital Transformation: Your Guide to Business Success

Digital Transformation is not just a buzzword or a passing fad businesses can afford to ignore. It’s the evolution of business.

12 min read

Ignition Community Live: Behind the Scenes of IntegrateLive!

You already know Inductive Automation helps build great SCADA solutions and information platforms ... but did you know they have also helped build an incredible friendship resulting in a new community that is uniting industrial automation changemakers from around the world? Learn more about this exciting new project as we are joined by Allen Ray (head of the Ignition Cross-Industry Collective) and Jeff Knepper (Canary Labs) for what is sure to be an entertaining episode where we look behind the scenes at what it takes to build a service-oriented community.

58 min video

Security Best Practices for Your Ignition System

Cybersecurity is a moving target. The techniques and technologies of yesteryear won’t necessarily protect your system in this highly interconnected era of IIoT-enabled systems. As attacks on industrial control systems become increasingly commonplace, it’s more vital than ever to stay up to date on the latest in security best practices to mitigate risk and maintain peace of mind.

53 min video

Variety of Connections, Unlimited Licensing Aid Cancer Therapy

Autolus Therapeutics is working hard to deliver life-changing benefits to cancer patients.

5 min read

Ignition Community Live: OEE Accelerator Built with Ignition Perspective

Understanding how your manufacturing systems and assets are performing is one of the first steps to real-time operational insights, identifying opportunities for improvement, and intelligent Smart Manufacturing initiatives. Overall Equipment Effectiveness (OEE) is the essential, industry-standard metric for capturing asset utilization and efficiency.

50 min video

Context is the Key to Unlocking Data

Daniel Voit and Keith Weerts of Blentech join Paul Scott to discuss the importance of context when it comes to data. They dive into how Daniel and Keith started on this path to unlocking the power of food production data, how Ignition played a crucial role in their development, and how companies can fully utilize their equipment in a short amount of time.

45 min episode

Turn Any Panel PC Into an Ignition HMI

The traditional human-machine interface (HMI) is a hardware-and-software solution used to view and track data in all kinds of industrial settings. Lately, supply-chain problems have led to long wait times when ordering traditional HMIs. But don't worry: It’s easy to turn any panel PC into an Ignition HMI solution, and in this webinar we'll show you how!

55 min video

The Business Value of Digital Transformation

Remus Pop from Riveron chats with Don Pearson about the meaning of Digital Transformation, Industry 4.0, and IIoT and the business value of the technologies developed for these initiatives. They further discuss the challenges and obstacles of implementation, how companies are handling global disruptions, and the outlook of our industry and the agents of change leading the charge.

34 min episode

5 Mobile-Responsive Layout Strategies

In our smartphone-dominated world, developers need to make HMI screens and applications that will look great on small, medium, and large devices. Are you familiar with the mobile-responsive layout strategies that make this possible?

55 min video

Ignition Community Live: Practical Ways to Use Ignition to Achieve Digital Transformation

The phrase "Digital Transformation" is taking the world by storm — but is there substance behind the hype? In this presentation, executives from 4IR will describe current trends in manufacturing digital transformation and show how these initiatives deviate from technology adoption cycles of the past. We will close with a technical showcase of specific, practical examples of Ignition techniques you can use today in support of digital transformation initiatives.

35 min video

Bringing Digital Transformation Into Focus

Today it seems like every company is embarking on a journey of Digital Transformation. While this is a necessary shift, only those companies that see the big picture will succeed at it, which means looking at not only the technological aspect of Digital Transformation but its wider impact on processes, people, and programs.

57 min video

Ignition Community Live: Ignition Platform Demo

In this Ignition demo, Inductive Automation’s Travis Cox shows the range of capabilities Ignition has, and how it’s the SCADA software of the future.

61 min video

Integrators Explore the Road Ahead

After navigating many unforeseen challenges in 2020 and 2021, how should system integrators move forward in 2022? The answer will be different for every integrator, which is why we’ve gathered a group of experienced integration professionals who work in a variety of areas and industries to talk about what lies ahead.

62 min video

What SCADA Systems Need in the Modern Era

Learn about the features you need to guarantee that a SCADA system is powerful and flexible enough to excel in the modern era.

10 min read

Sustainable SCADA for Your Water Utility

Sales Engineering Manager Kent Melville explains how to build budget-friendly water SCADA systems with five small steps for sustainable SCADA.

46 min video

Two Companies Assist University with Engineering Education

For engineering students, experience with real-world tools can be very beneficial.

5 min read

Improved Efficiency and Reporting for Large Manufacturer

Atlas Copco is a global company based in Stockholm, Sweden, with 40,000 employees worldwide.

5 min read

Top 10 Design & Security Tips to Elevate Your SCADA System

Inductive Automation explains why It's more important than ever to embrace modern technology and security standards through collaboration with IT and OT.

61 min video

The Art of Displaying Industrial Data

There is a huge amount of data out there and a great deal of power and insight that we can gain from it — if we can just bring it all into focus and make it more manageable. Many industrial organizations are accomplishing this by building sophisticated HMI, SCADA, and MES projects with the Ignition Perspective Module.

59 min video

Ignition Community Live: Flexibility, Scalability, and Mobility for Clover South Africa

Leading South African branded foods and beverages group Clover Industries adopted Ignition to meet crucial system technology requirements. In this discussion, Francois and Deon from Clover share their needs, architecture overview, and multi-site implementation approach, including new standards and templates and the coordination of several system integrator partners. We'll also talk through the valuable lessons learned and challenges overcome during implementation during the COVID-19 pandemic.

58 min video

Creating Opportunities with Ignition Worldwide

Inductive Automation’s very own Annie Wise joins us to discuss the benefits, successes, and importance of our international distributor program. We hear about how the program got off the ground, the story of our first distributor, what territories currently have partners, and how the program has grown over the years. Annie shares what qualities we look for when partnering with new distributors and tells us about the new international track at the 2021 Ignition Community Conference.

12 min episode

Improving Sustainability in Waste Management